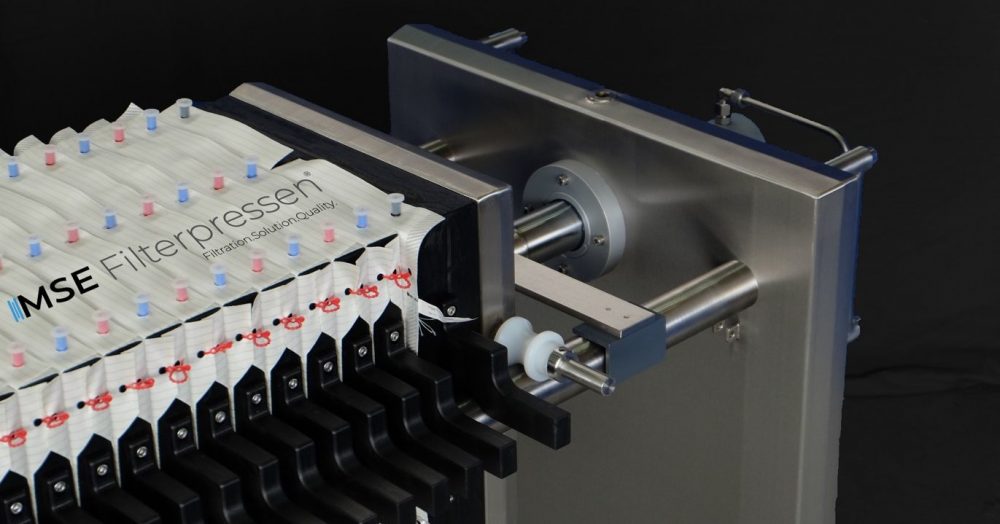

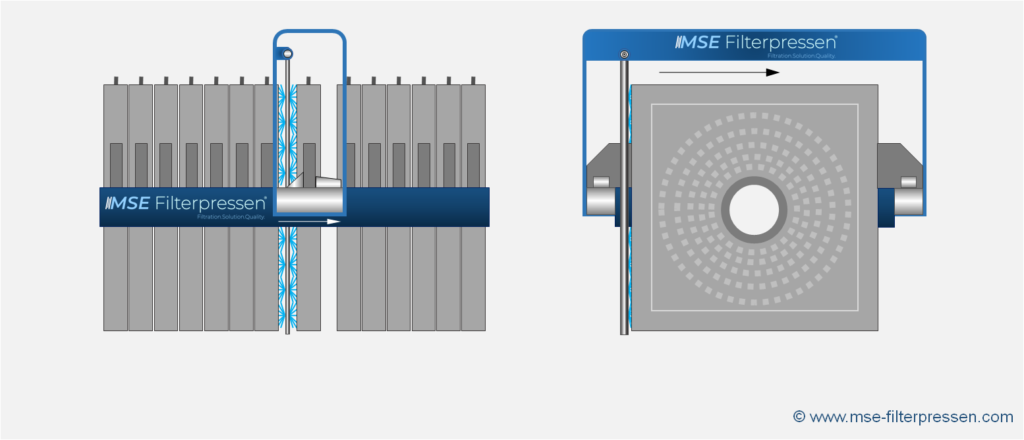

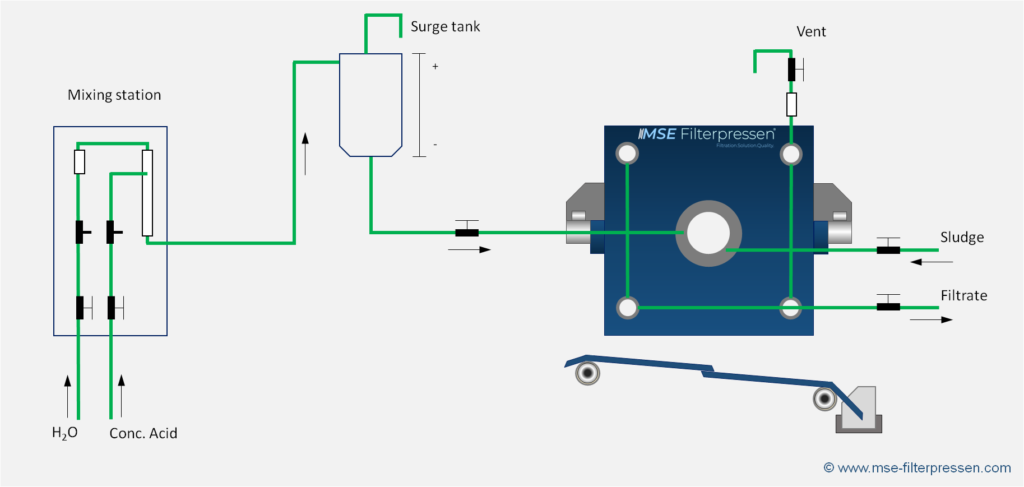

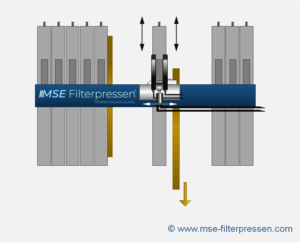

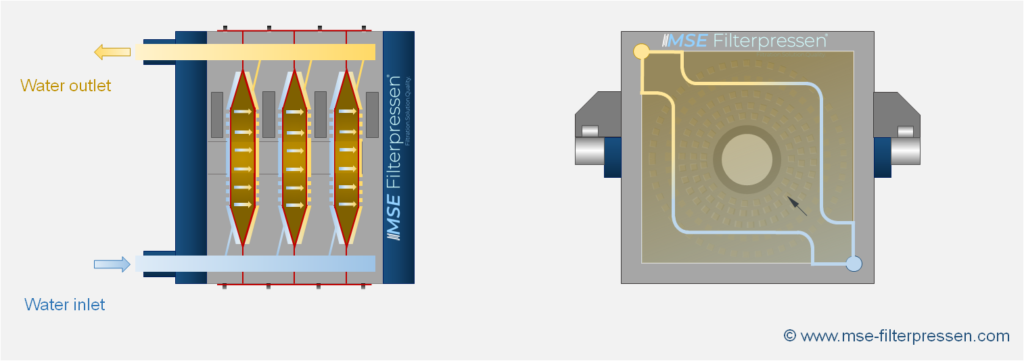

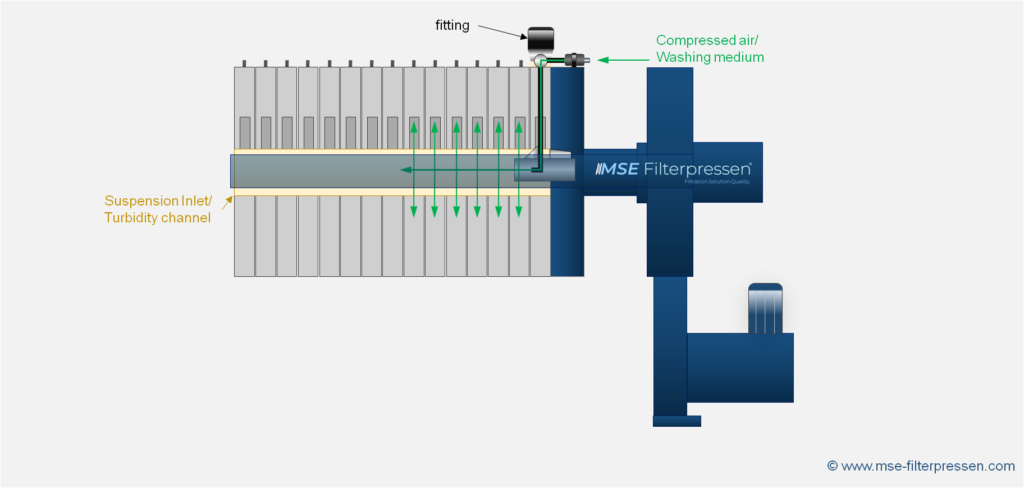

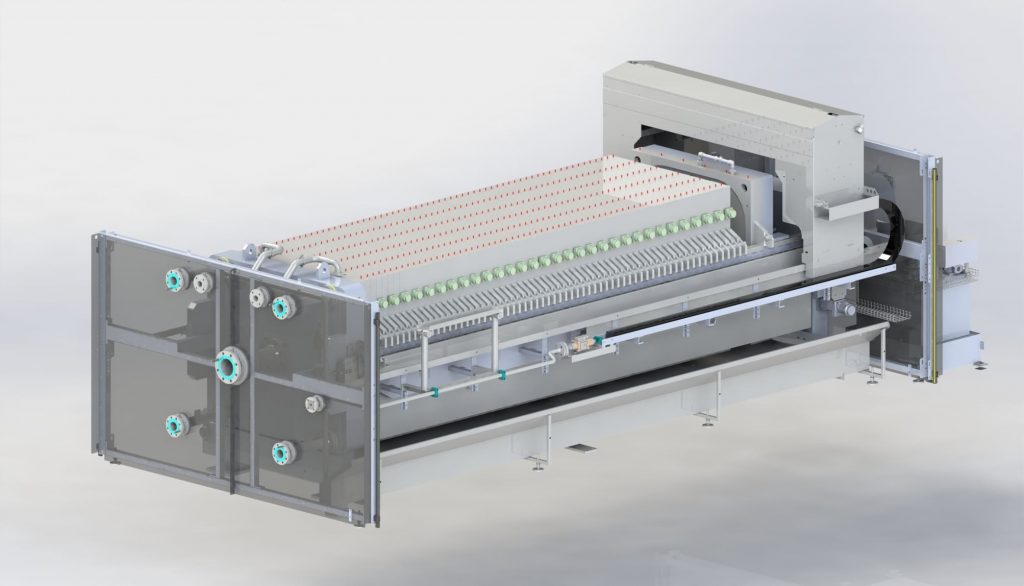

On the one hand, stainless steel filter presses differ only slightly from conventional filter presses. The basic architecture, the working principle and process technology are identical. However, the difference is in their structural protection measures. Depending on the application area (chemical, pharmaceutical or food industry), certain guidelines must be adhered to. MSE stainless steel filter presses comply with the high hygiene and purity standards both in design and processing. With the stainless steel filter press, all components in contact with the product (with the exception of the filter plates) are covered with high-quality stainless steel. This also provides optimum protection against corrosion. In special cases, the filter presses can be made entirely of stainless steel or is stainless steel-plated.

FDA-COMPLIANT SOLID-LIQUID SEPARATION WITH THE MSE STAINLESS STEEL FILTER PRESS

A large number of materials with different properties are used in the food sector in particular. Here, especially care must be taken to ensure that no ingredients are released into the food. The law stipulates a FDA certification for this. Accordingly, all materials used must be FDA-certified. The FDA certification stands for high purity and durability. Each component such as the filter plates, filter cloths and piping systems complies with the FDA guidelines. This contributes to high hygiene and safety requirements. MSE Filterpressen also supports you in clarifying all necessary conformity declarations in order to counteract the increasing directives in the food and beverage industry.