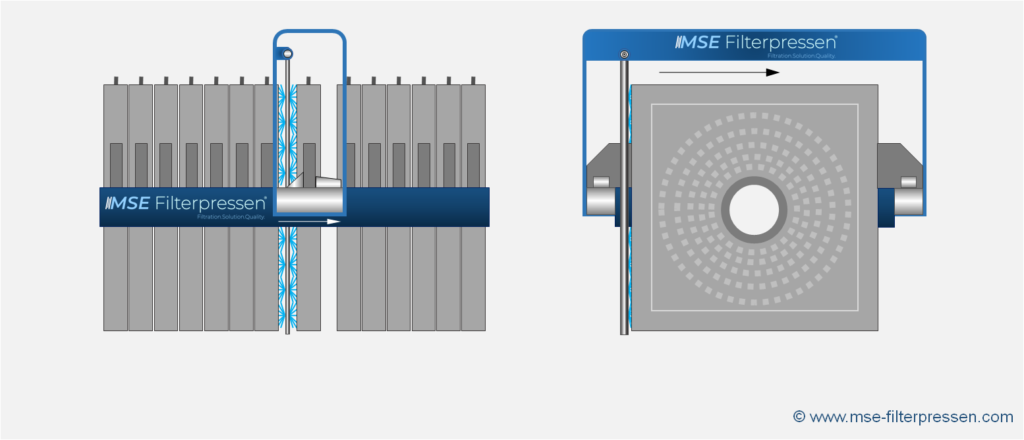

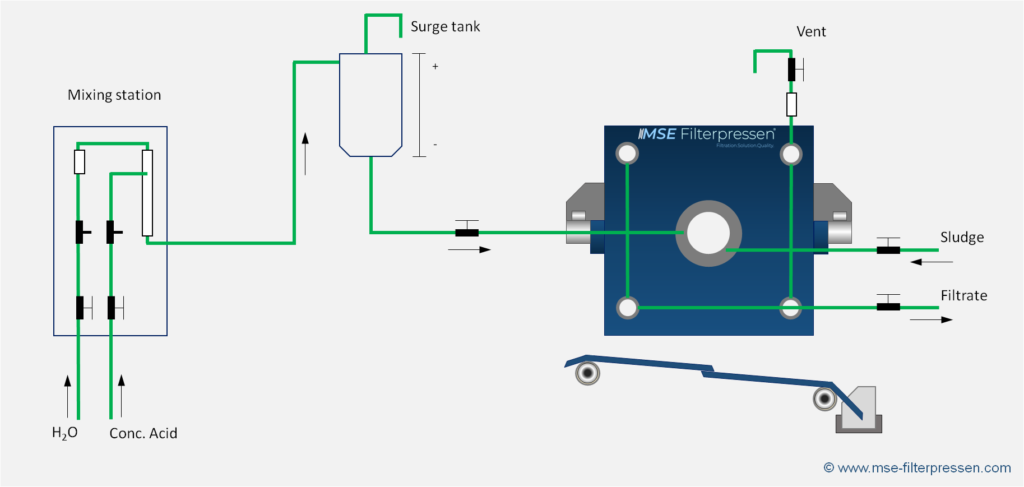

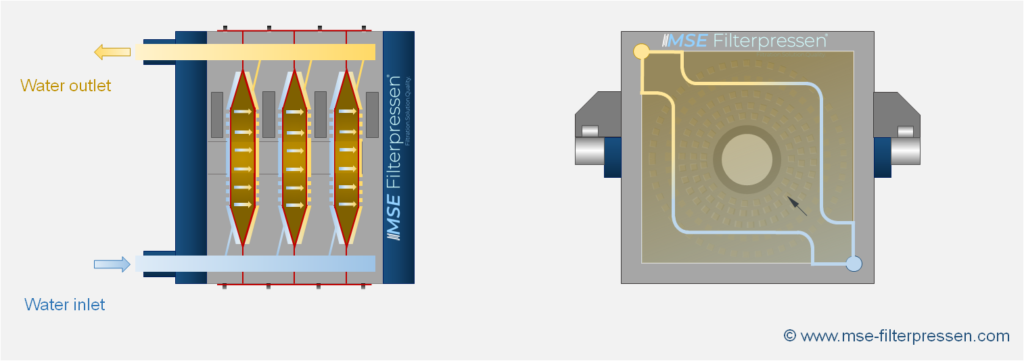

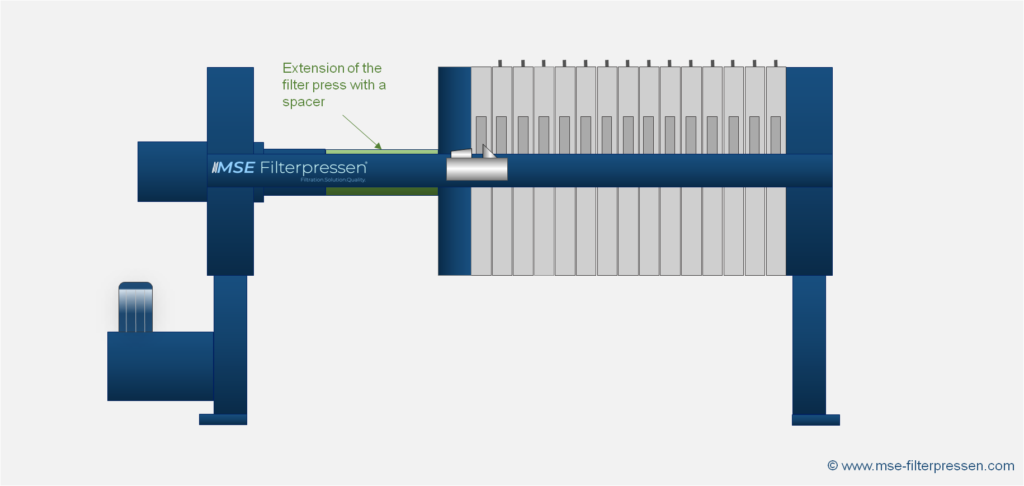

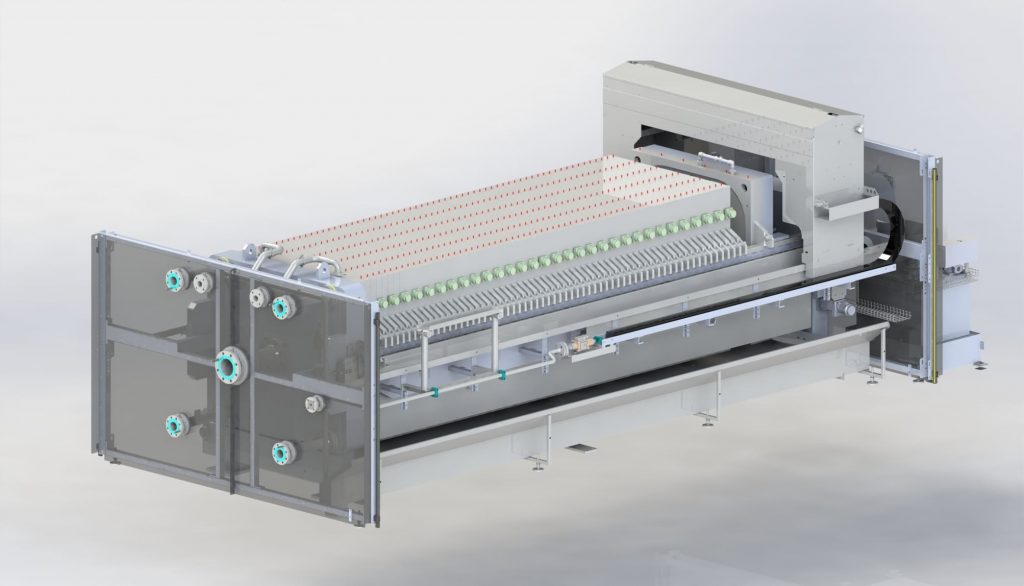

On the one hand, rubberised filter presses differ only slightly from conventional filter presses. The basic architecture, the filtration principle and process technology are identical. However, they differ in their surface properties. Based on the decisive properties of the flexible material, the rubberised filter press is mainly used for the filtration of particularly aggressive suspensions and environments. The aggressive suspensions include, for example, solvents or acids. In this context, the conventional painting of the steel parts is no longer sufficient.

THE RUBBERIZED FILTER PRESS OF MSE AS PROTECTIVE MEASURES AGAINST AGGRESSIVE SUSPENSIONS

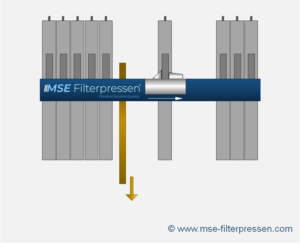

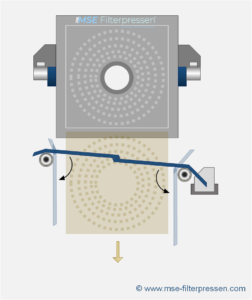

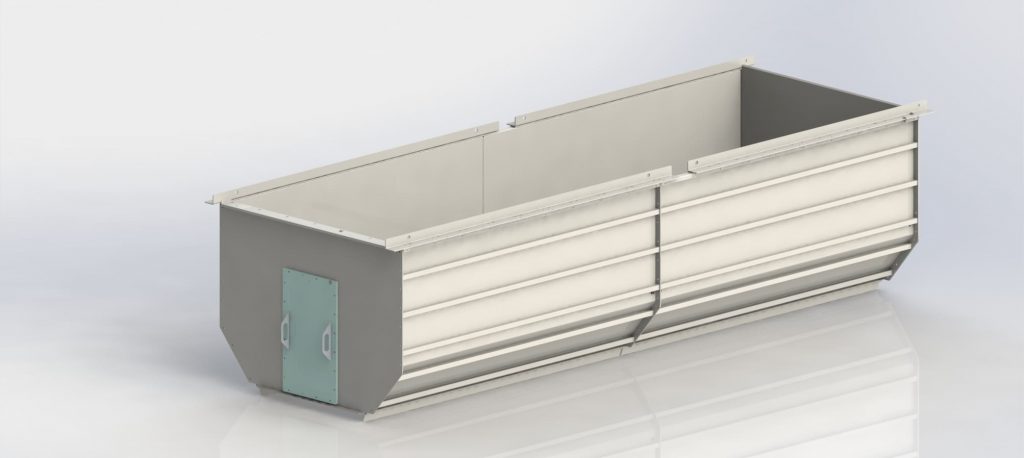

In a complex process, the load-bearing filter press components are coated with a layer of 3mm thick plastic. In the case of the rubberised filter press, the hydraulic stands, feed stand, pressure plate and supporting beams are hard rubberised and the smaller components are made of polypropylene. It is also possible to rubberise only the components in contact with the product, such as the feed stand and the pressure plate. The composition of the rubber coating depends on the special surface requirements of our customers.