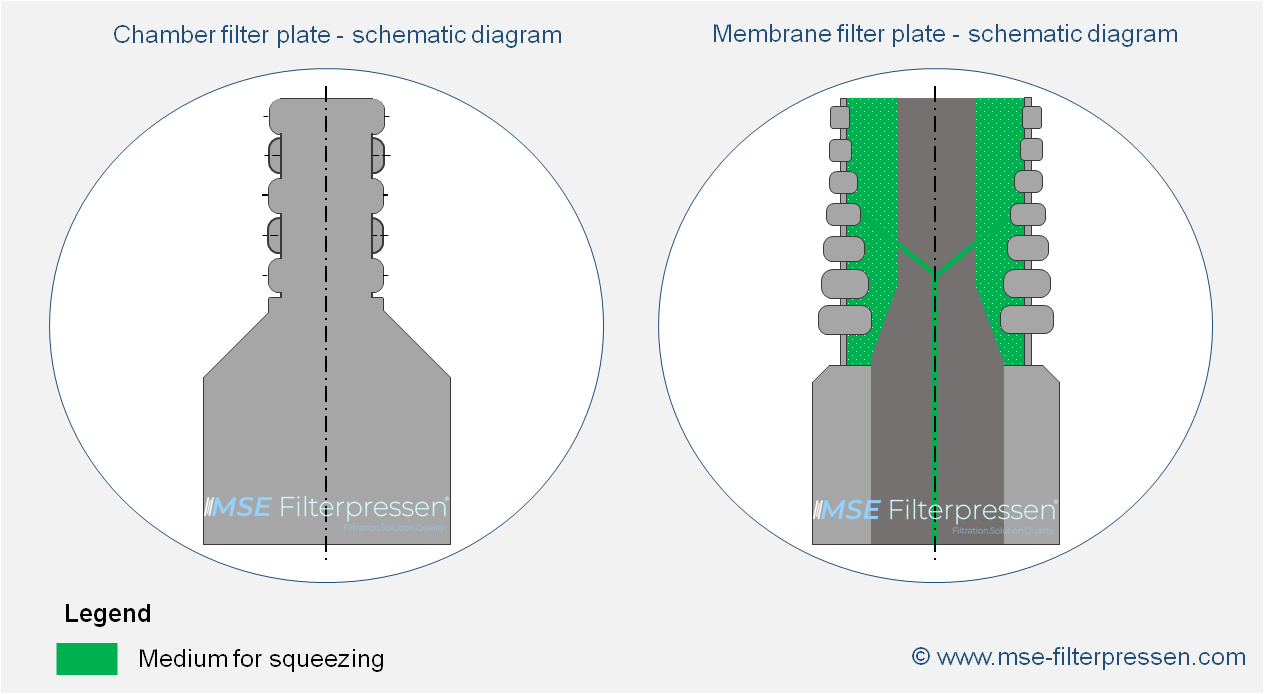

Filter press plates for chamber filter presses and membrane filter presses are primarily chemically resistant and pressure-resistant plastic plates made of PP. Together with the overhanging filter cloth, these form the process space for cake filtration in the filter press and are mainly responsible for solid/liquid separation. Special materials for higher temperatures up to +130°C and for lower temperatures down to -10°C are also available for continuous operation. The drainage surface integrated in the filter press plates is designed with nubs or grooves. This supports the filter cloth on the one hand and allows the filtrate to flow off in a defined manner on the other. Process-technical parameters for the selection of a filter plate for your individual application are the filter area, the chamber depth or the filter cake thickness and the degree of dewatering. This results in the chamber or cake volume as well as the filter plate type. Essential aspects of the design depend on the optional process steps such as filter cake washing, filter cake drying as well as core blowing and much more. The criteria for selecting the right filter plate specifically include:

-

- Chemical resistance

-

- Differential pressure resistance

-

- Temperature stability

-

- Filter cloth support

-

- Drainability (grooves, nubs, with/without membrane technology)

-

- Handling