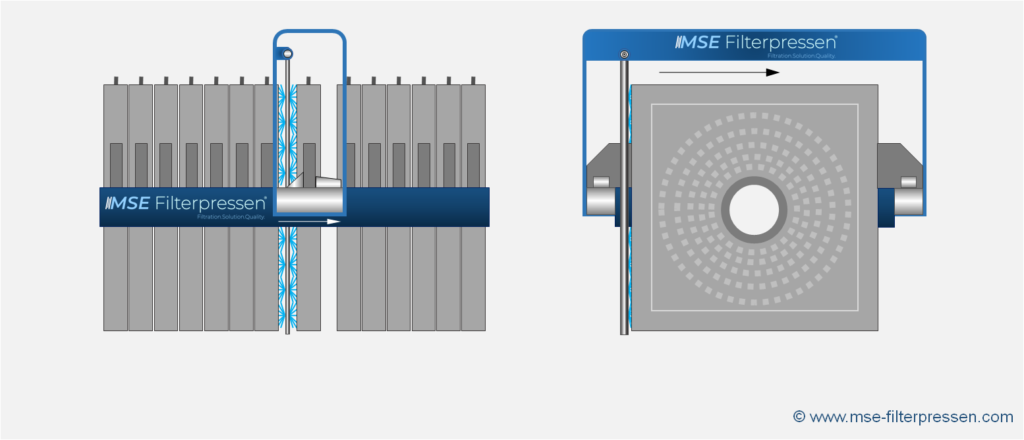

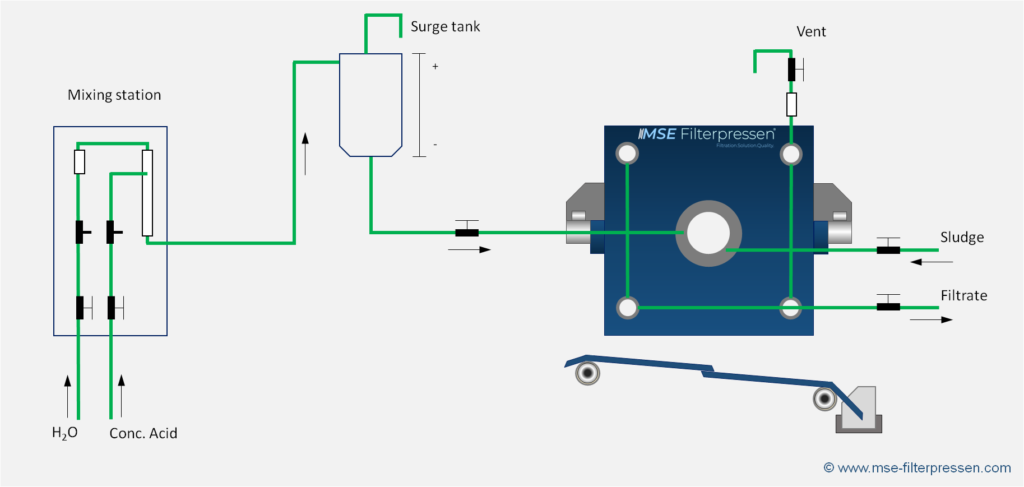

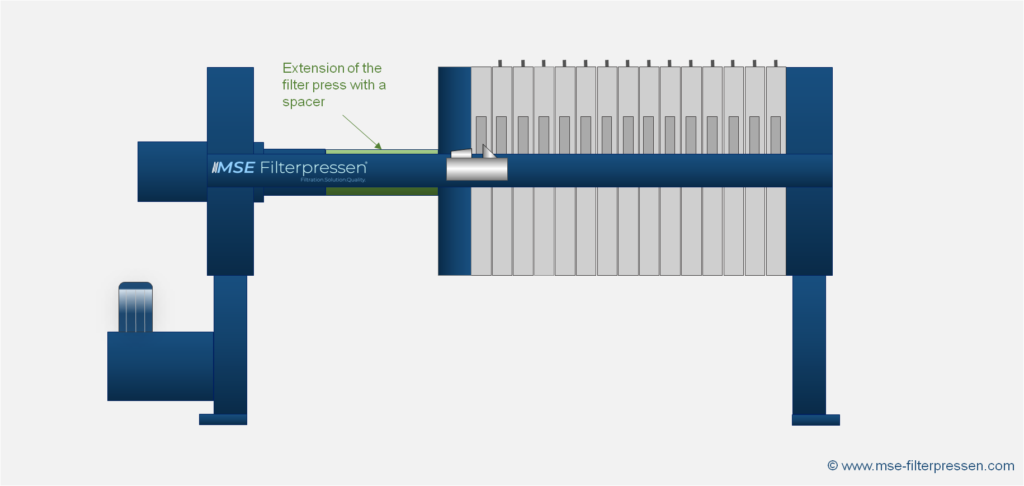

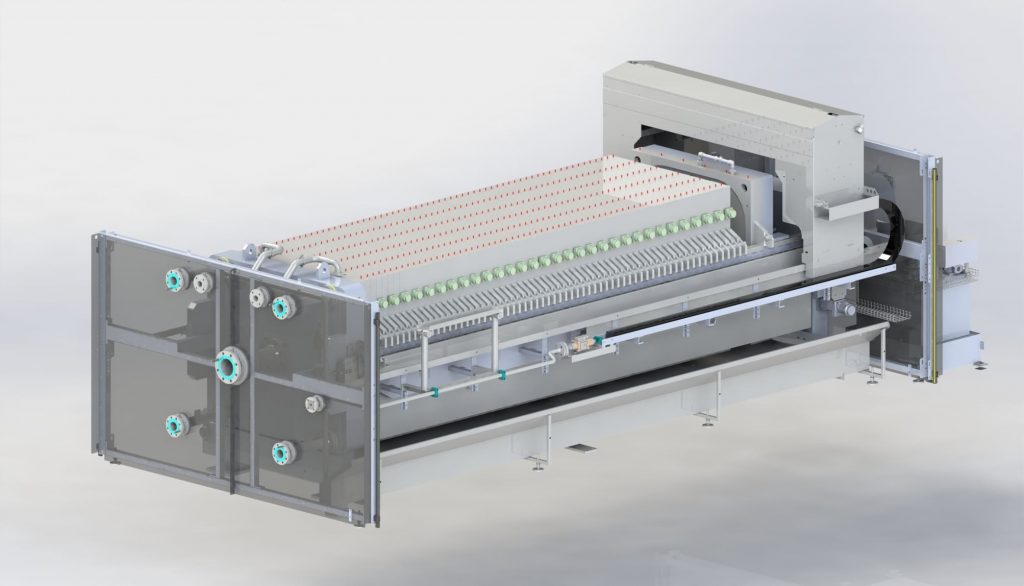

On the one hand, ATEX filter presses differ only slightly from conventional filter presses. The basic architecture, the working principle and process engineering are identical. However, the difference is in their structural protection measures. Here, the ATEX filter press, with its specific requirements, complies with the ATEX directives. As a result, these types of filter presses are designed for a high level of safety and explosion protection.

ATEX „ATMOSPHÈRES EXPLOSIBLES„

ATEX derives its name from the French term „ATmosphères EXplosibles”. It consists of two EU directives governing explosion protection and thus the equipment and working environment in an environment with an explosive atmosphere. ATEX filter presses are especially used in filtration processes in the chemical, petrochemical, oil and gas extraction, mining, food and waste water sectors. With their design, as well as the selected materials, they comply with all the requirements of the ATEX certification in potentially explosive areas.