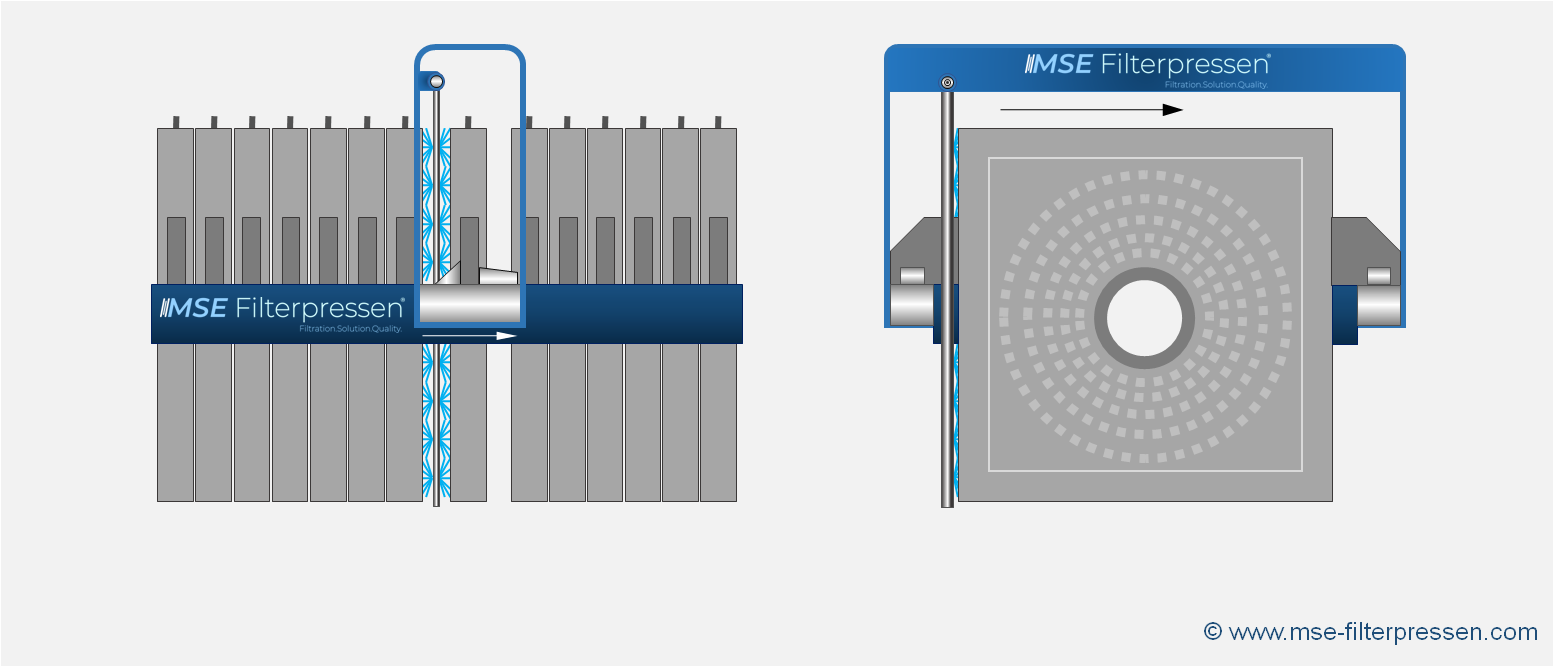

The industry-leading filter cloth washing system from MSE Filterpressen is a device that uses PLC logic controls to ensure fully automatic cleaning of filter cloths without operator intervention. The cleaning is done using water that is sprayed on the surface of the filter cloths at a high pressure. The washing trolley is a frame construction which moves on track rollers and guide rails and is coupled to the automatic plate shifter.

Filter cloth washing device

FILTER CLOTH WASHING DEVICE FOR FILTER PRESSES

The automatic plate shifting first pulls the filter plate into its position. The washing device then positions itself in relation to the filter plate. The swivelling nozzle holder then moves along the filter plate and cleans it via the water jet which flows out of the arranged nozzles. The system works completely automatically and also prevents excessive contamination of the filter cloths. This is particularly important in the edge or sealing area of the filter cloths.

OPTIMISATION OF THE FILTRATION THROUGH THE USE OF A FILTER CLOTH WASHING PLANT FOR FILTER PRESSES

Contaminated filter cloths are the cause of many problems when operating a filter press (e.g. a chamber filter press and a membrane filter press) and lead to:

-

- Long filtration times with moderately good results

-

- Destruction of the filter cloths as a result of high flow loads

-

- Unplanned shutdown of the plant

-

- Damage to the press design as a result of differential pressures

HIGH SAVINGS THROUGH THE USE OF AN AUTOMATIC FILTER CLOTH WASHING PLANT

Ultimately, every filtration costs real money when the filter cloth is in poor condition. The solution is to use an automatic device to clean the filter cloths. The filter press works more efficiently with a consistently good condition of the filter cloths and less operating effort. The service life of the filter cloths may potentially be significantly extended. The cleaning of the cloths takes place automatically without supervision, e.g. also on weekends or at night, during the downtimes. In one specific case (in a gravel plant), it took 12-14 hours per press to clean two filter presses (using a high-pressure cleaner).

Today, the automatic cleaning of one filter press takes only 3 hours. This not only reduces the personnel costs but also contributes to an improvement of the working conditions for the operating personnel. Filter cloth washing plants can also be retrofitted to an existing filter press (chamber filter press / membrane filter press) of all makes. There are different types of equipment for cleaning the filter cloths. The selection depends on the available overall construction height, the required splash guard and the desired degree of automation. We will be happy to advise you on which of the variants is the most suitable for your application.

SEE MORE

PRODUCT PORTFOLIO

In the product area, you can find a wide range of different filtration plants (chamber, membrane and stainless steel filter presses, and much more). In addition, you will find a wide range of by-products, such as feed pumps, filter elements as well as automation and expansion modules.

APPLICATIONS OF DEWATERING PLANTS

Due to their excellent drainage properties and process technology variety, filter presses are used in different applications such as sewage, chemical, mining and much more. Within the individual application areas, you will find a list of exemplary application areas.

MSE SERVICES

MSE Services offers you a comprehensive range of transparent and clearly structured services for your filter press system. As a reliable service partner, we accompany you throughout the entire life cycle of your system and ensure its productivity and availability.