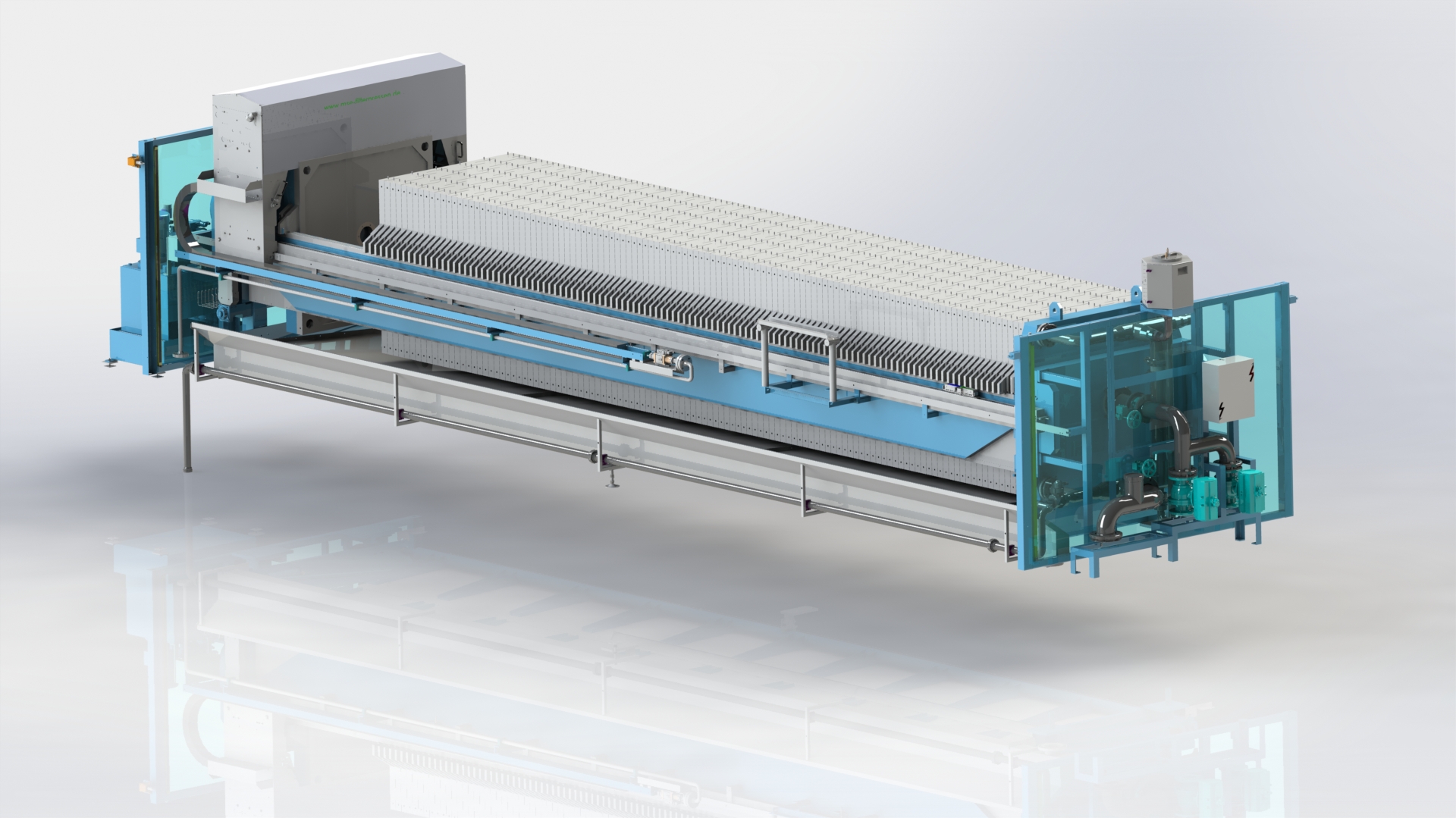

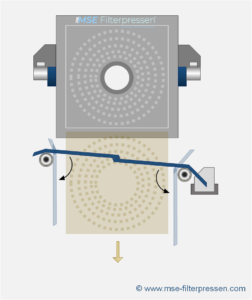

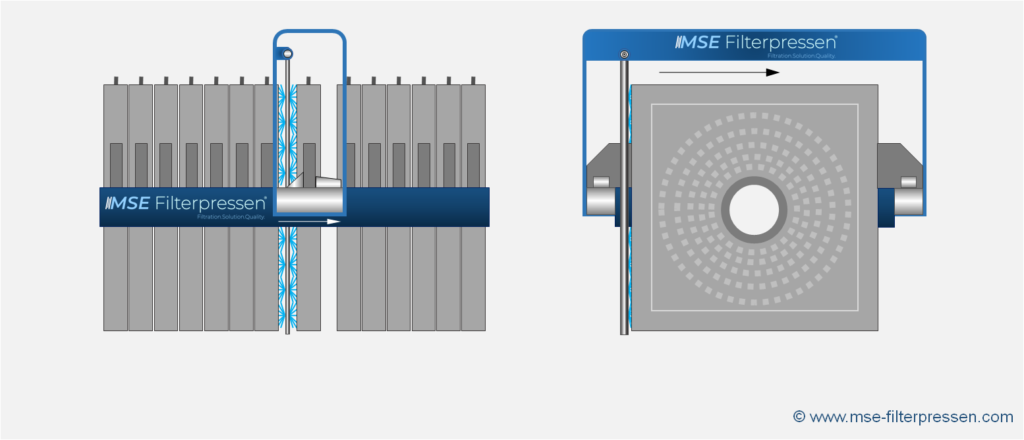

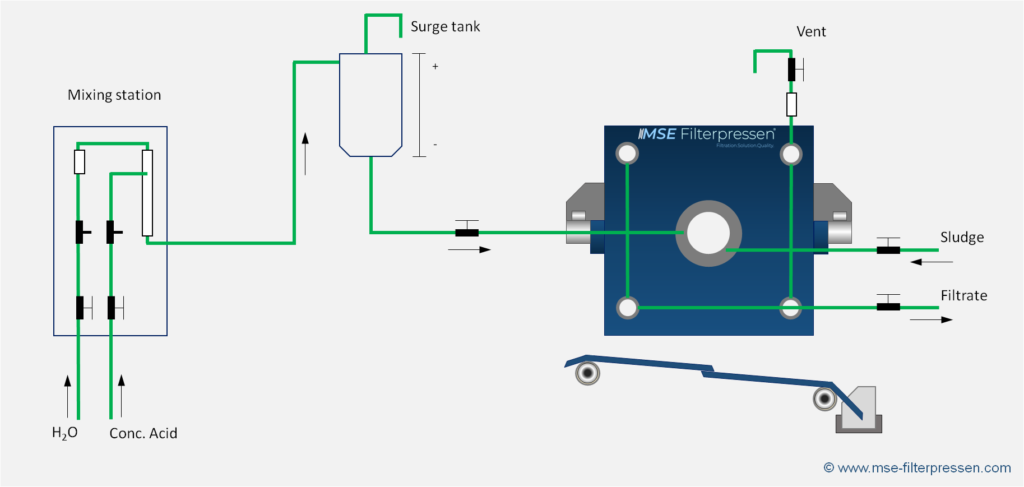

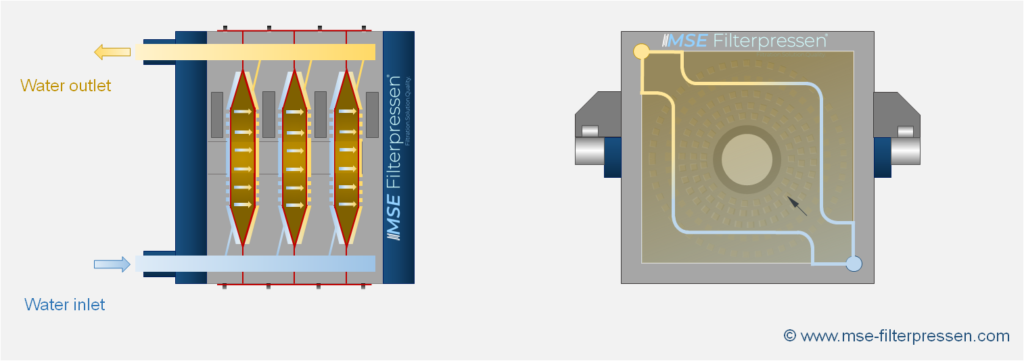

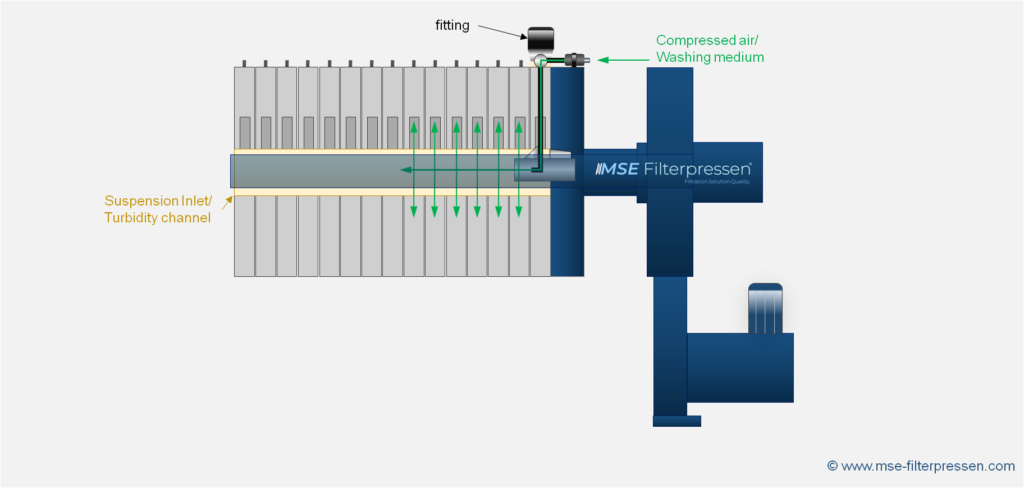

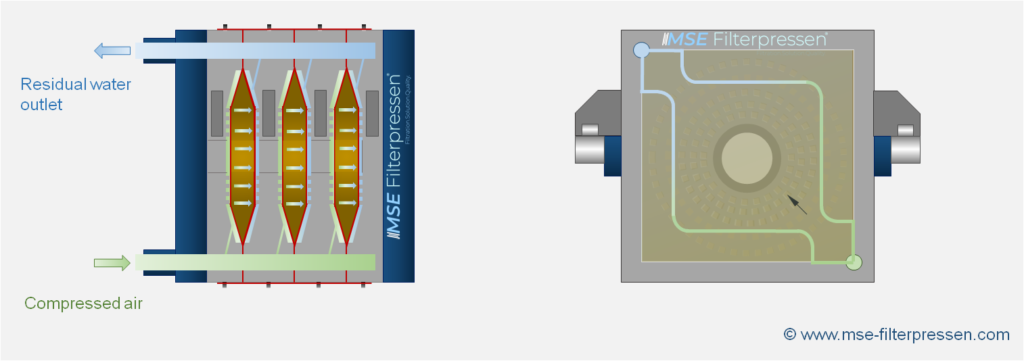

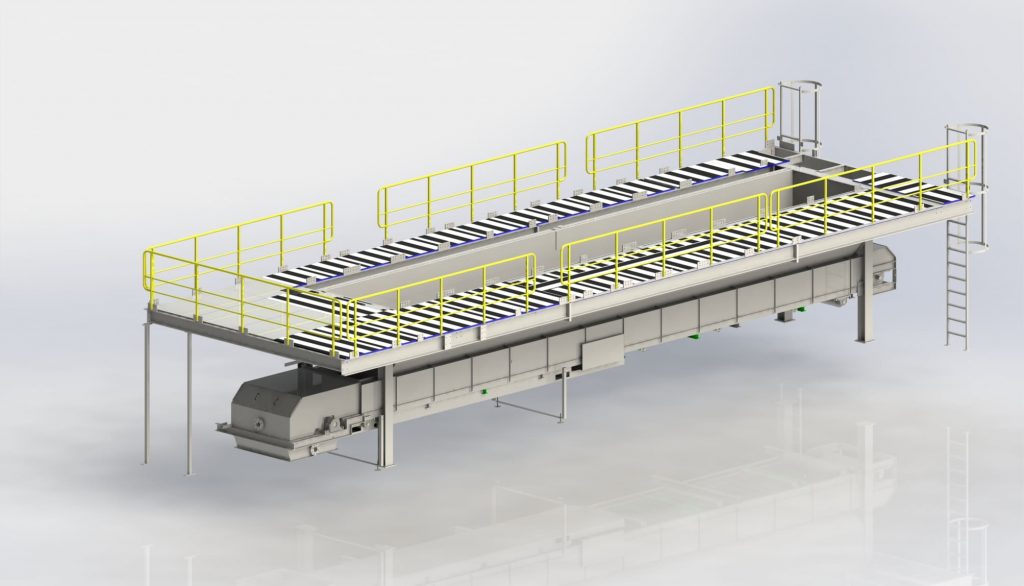

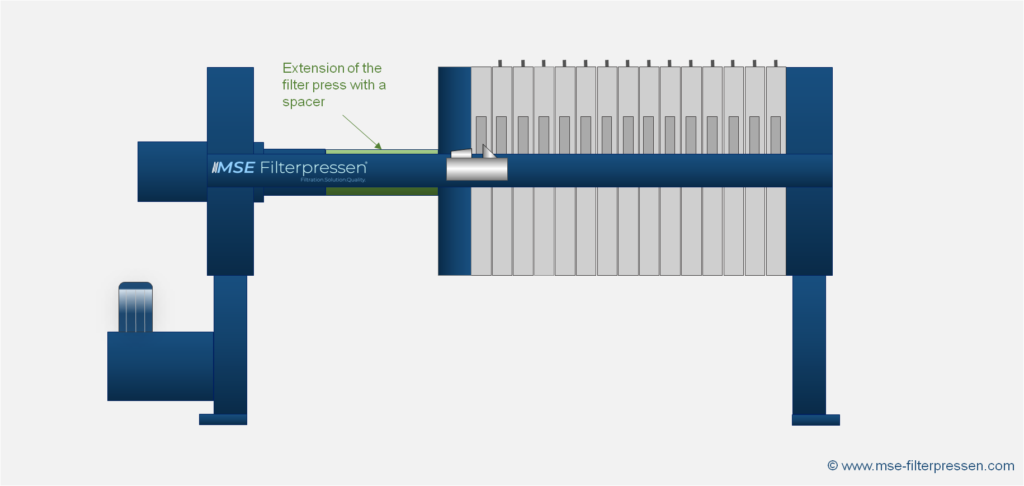

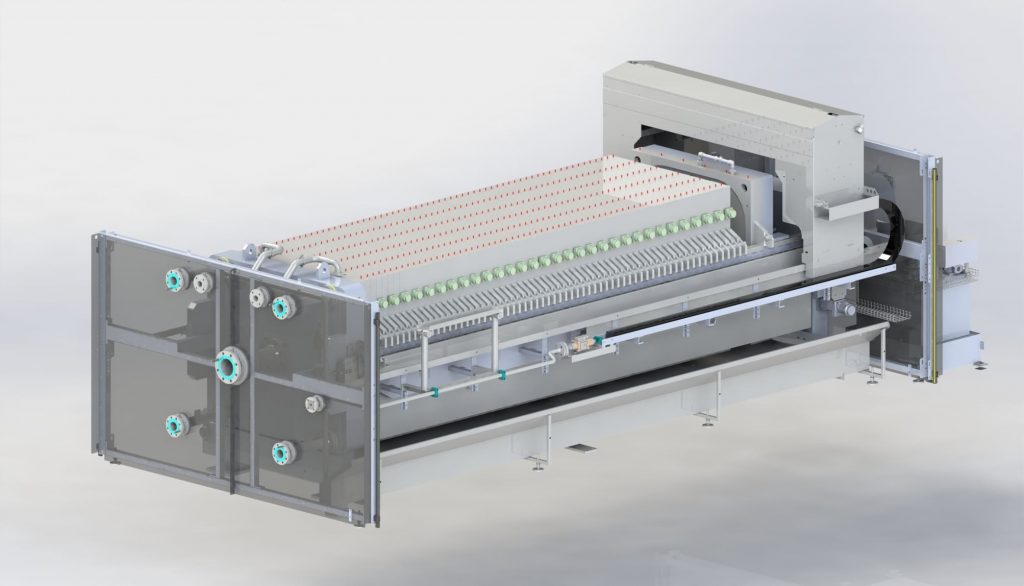

In addition to its simple and inexpensive design, the chamber filter press is also a powerful and reliable filter press. The type of suspension to be filtered (e.g. mining, chemical or pharmaceutical industry) is irrelevant. In order to meet the different requirements of industry and municipalities, MSE chamber filter presses are designed for this in modular design. The solid and heavy-duty steel filter press frame, which consists of the following main components, forms the basis: Feeding stands with filtrate outlet (head piece), hydraulic stands with locking cylinder (pressure piece), cross beam and side rails on which the individual filter plates are arranged accordingly including filter cloths. The plate pack also consists of uniform chamber plates with a cut-out of 15-50 mm for holding the puncture-proof filter cake. Polypropylene (PP) is used as the chamber plate material in the standard version.

HIGH PERFORMANCE AND HIGH DEGREE OF CONFIGURATION FOR YOUR CHAMBER FILTER PRESS

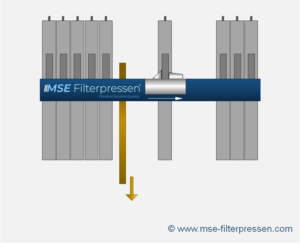

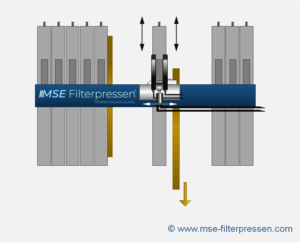

The chamber filter press can be configured as required depending on the series. These include, for example, automatic plate shifting, a vibrating device or core blow-out and/or core rinsing. Taking different influencing factors into account, chamber filter presses achieve a solids content in the filter cake from 30 to over 50 percent. The intelligent filtration principle leads to immense cost savings in the waste water sector, for example. The operation of the chamber filter press is designed for a feed pressure of up to 30 bar in order to successfully filter even the finest particles.