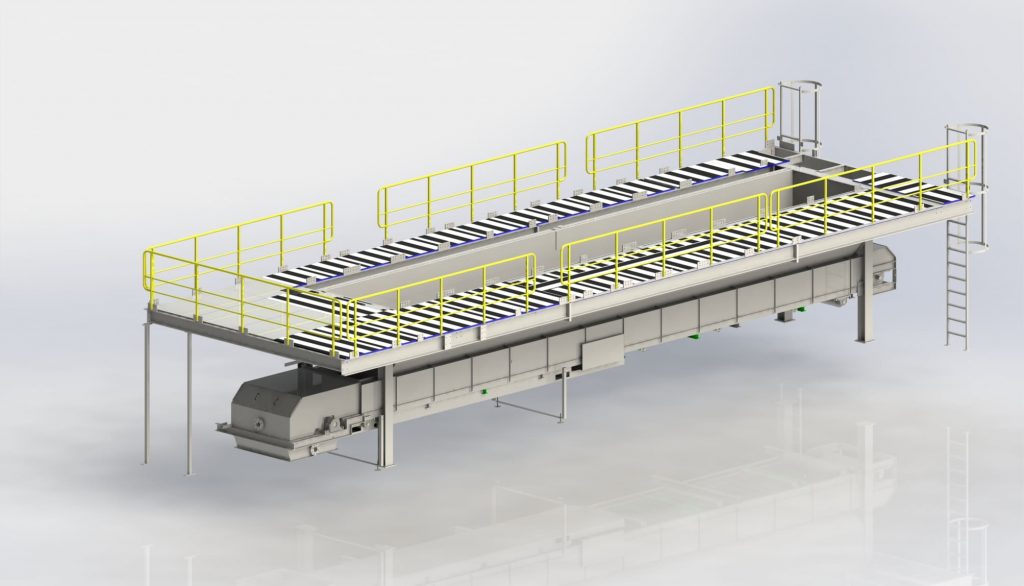

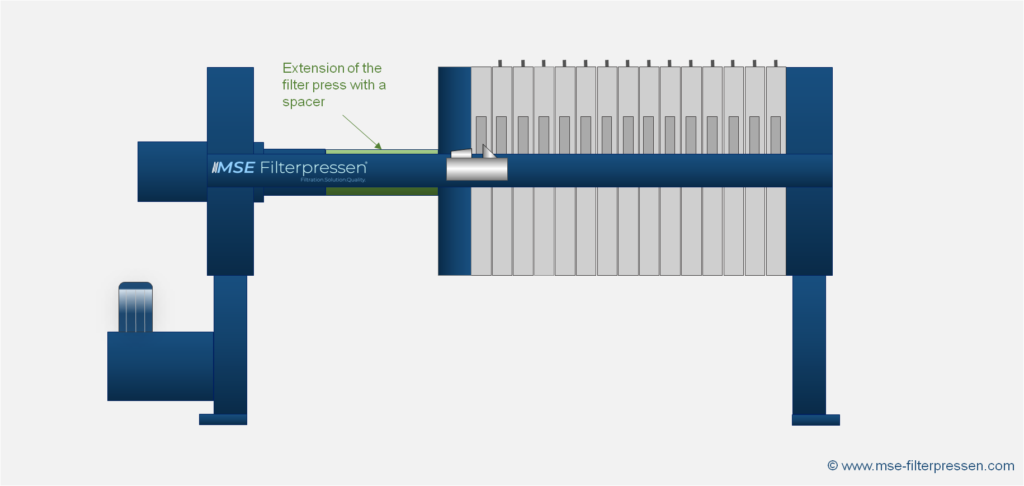

When it comes to maximum productivity and special tasks in solid-liquid separation, there is no way around a CellTRON® series filter press. This high-performance filter press is suitable for both medium and heavy performance levels for the most challenging filtration tasks. The CellTRON series is also upgradeable in modules and equipment features and can be adapted to your specific needs and requirements. For perfect dewatering of tailings, MSE high-performance filter presses are therefore state-of-the-art in terms of technology and functionality.

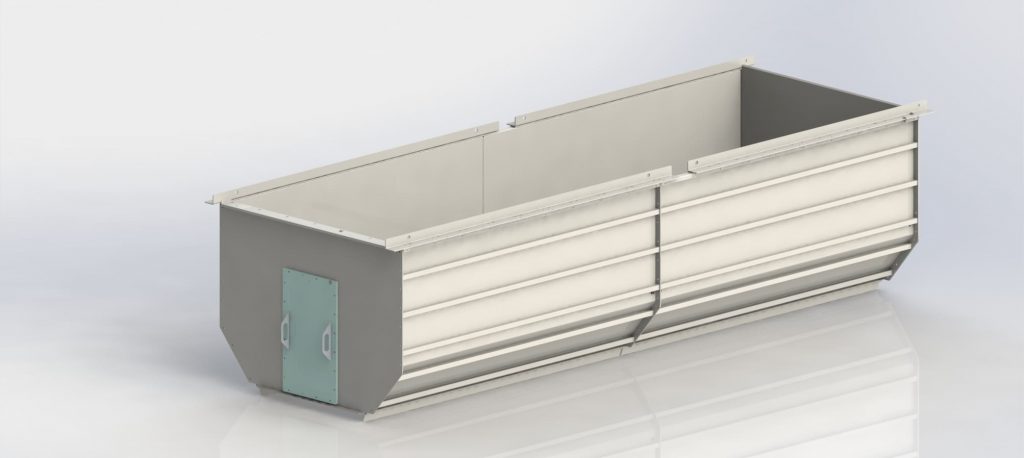

CellTRON®-Light filter press

BENEFITS OF MSE CellTRON® FILTER PRESS

- Suitable for the most demanding applications and harshest environments requiring the highest standards of safety and efficiency

- Max. machine protection due to all-round splash guard

- Fully automatic roof and rolling door opening

- Automatic & reproducible cleaning of rolling doors

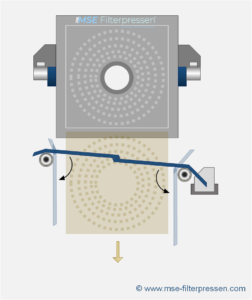

- Fully automatic operation through intelligent filter cake removal system and lifetime error message

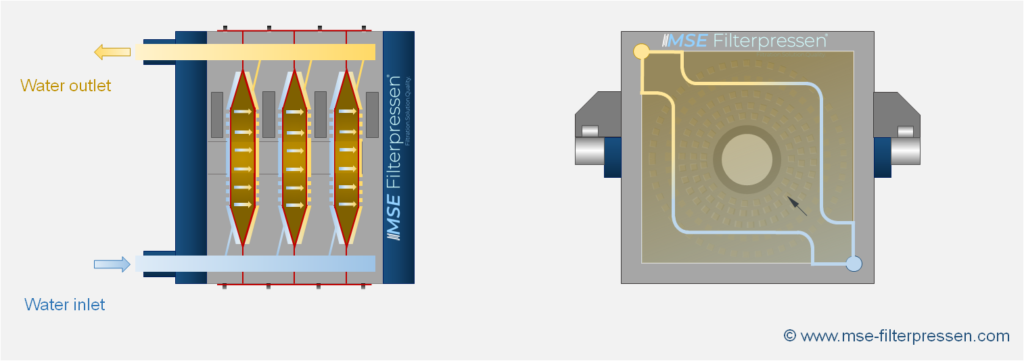

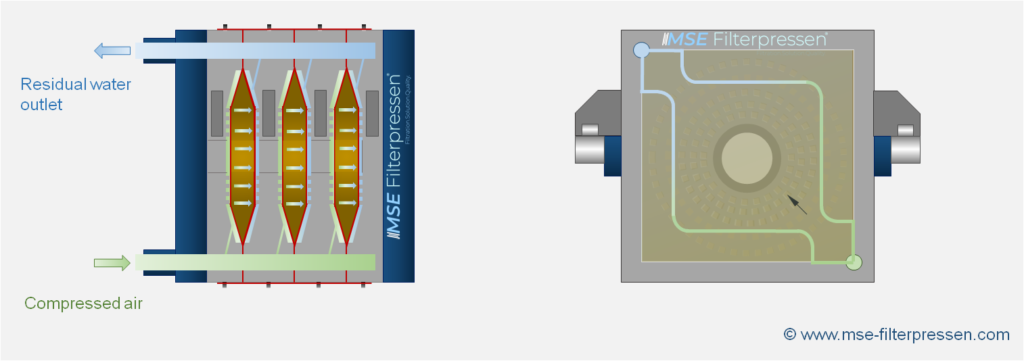

- MSE filter plate technology for lowest moisture

- Hygienic Design upon request

- Low maintenance

- No cost-intensive revision after a short operation time

HIGHLY EFFECTIVE PRODUCT FILTRATION - FROM MEDIUM DUTY TO HEAVY DUTY

AREAS OF APPLICATION

OPTIONAL MACHINE EQUIPMENT

FILTER PRESS PRE-LAYOUT

Calculate the size of your chamber filter press with our online calculator. This service will assist you in planning and sizing your filter press machine. Please note that this result is an estimated value based on solid-liquid separation. We will be pleased to support you with your detailed calculation of your dewatering plant. Please contact us for more.

SEE MORE

AUTOMATION MODULES

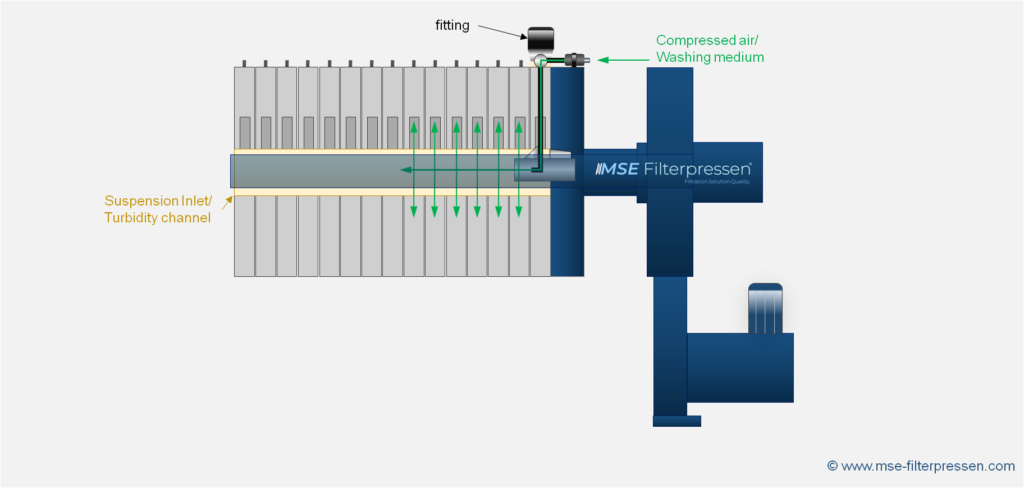

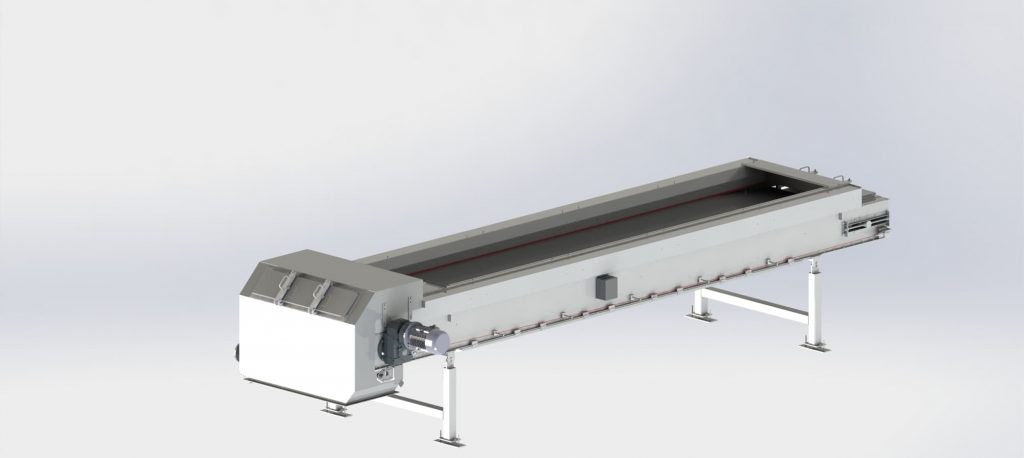

With the automation & expansion modules, we offer our customers advanced solutions to increase the productivity and flexibility of your filter press. From this, MSE generates custom-fit and tailor-made solutions – from the single machine to the fully automated turnkey filtration system.

MSE SERVICES

MSE Services offers you a comprehensive range of transparent and clearly structured services for your filter press system. As a reliable service partner, we accompany you throughout the entire life cycle of your system and ensure its productivity and availability.

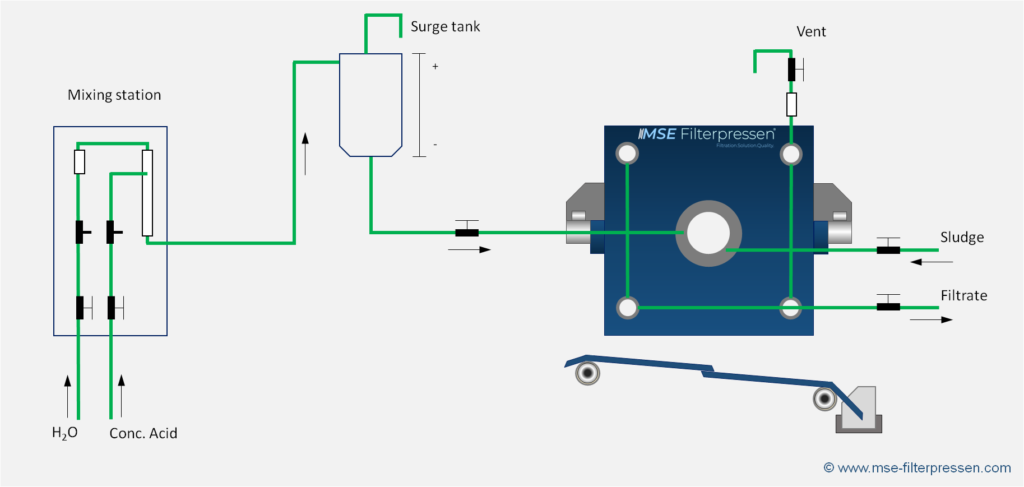

PROCESS TECHNOLOGY

Cake filtration is a mechanical process for the separation of solid-containing liquids. It pertains to surface filtration like cross-flow filtration. In contrast to depth filters, the actual separation effect takes place through the filter cake, which settles on the filter cloth.