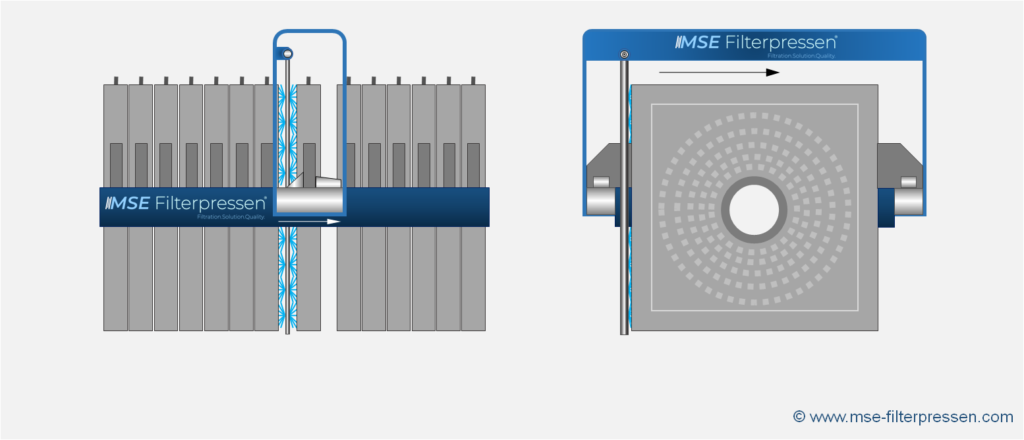

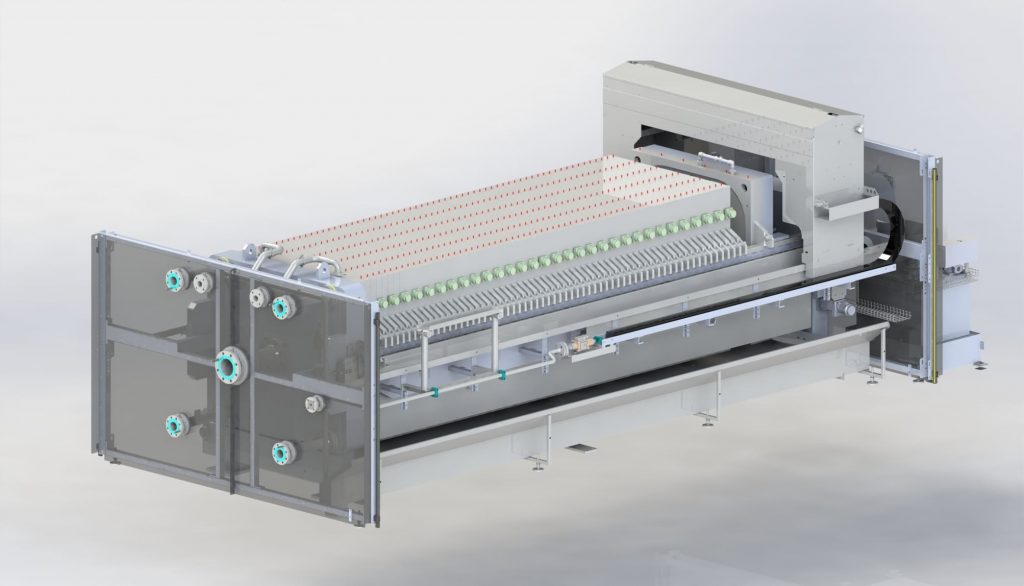

Semi-automatic filter presses according to EN 574 are conventional filter presses with regard to their working principle and process technology, however represent a simplified and cost effective solution for the reliable operation with respect to operation and safety measures. This type of filter press is distinguished by a special, a rail-mounted two-hand control panel. The filter press with two-hand control is used in particular when the space on site is limited or a higher degree of automation is not required. Accordingly, a conventional version of the protective device is no longer effective.

REDUCED PROCUREMENT COSTS AND SIMPLE OPERATION – THE SEMI-AUTOMATIC FILTER PRESS WITH TWO-HAND CONTROL FROM MSE

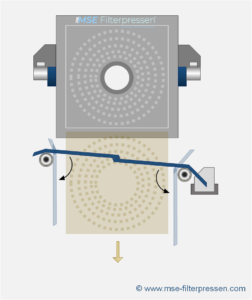

Based on the safety technology requirements, an intelligent two-hand control is implemented, for example, for moving the filter plates by means of automated plate transport. This functional principle thus prevents the operator from reaching into the working area. Complicated mechanical designs including further safety measures are not necessary. The combination of two-hand control, plate transport and the elimination of further attachment measures reduces the procurement costs and also guarantees consistently simplified operability with complete protection against mechanical hazards.