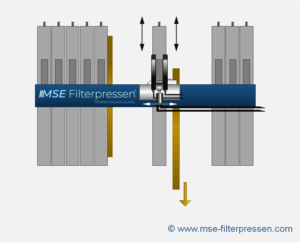

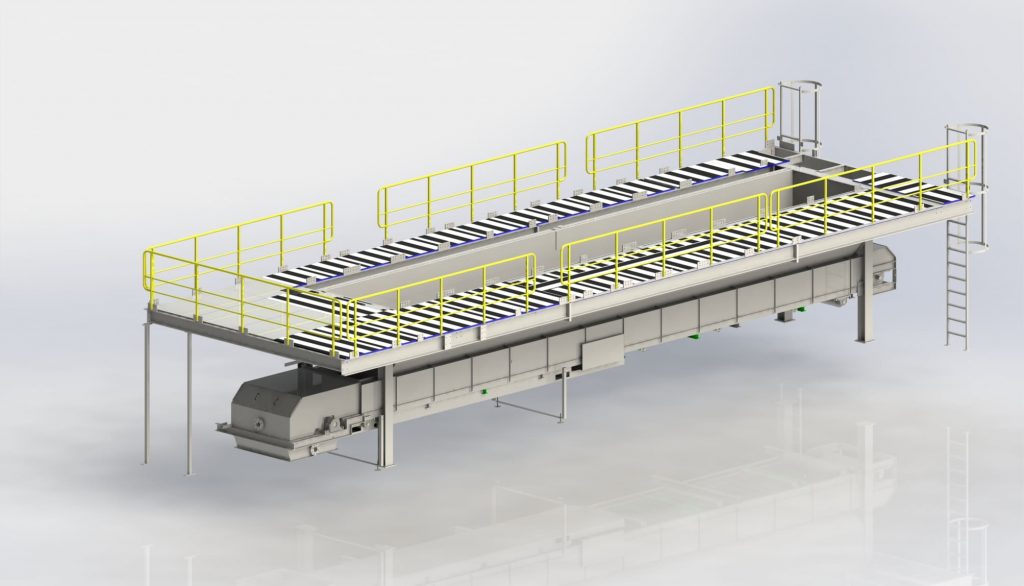

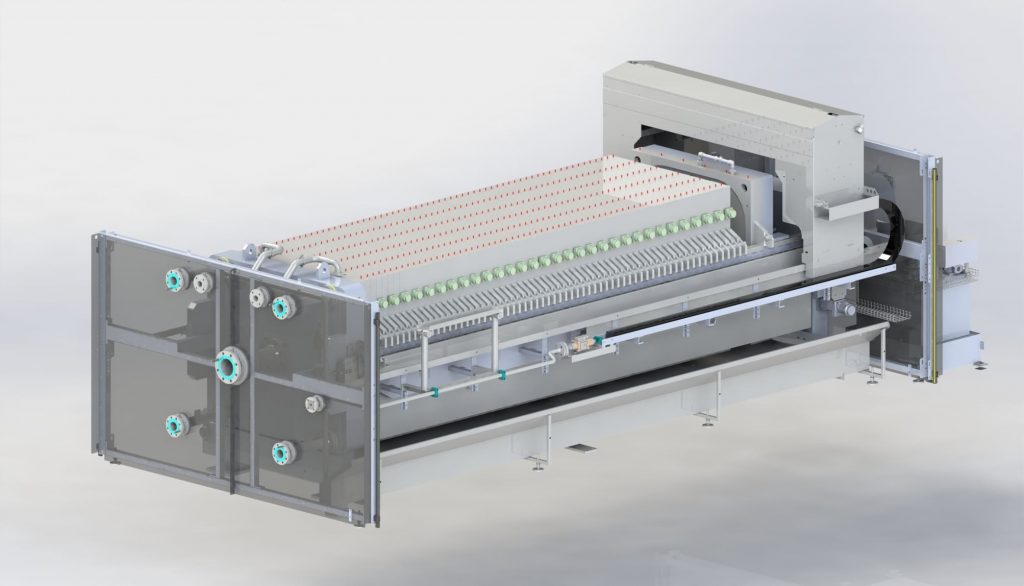

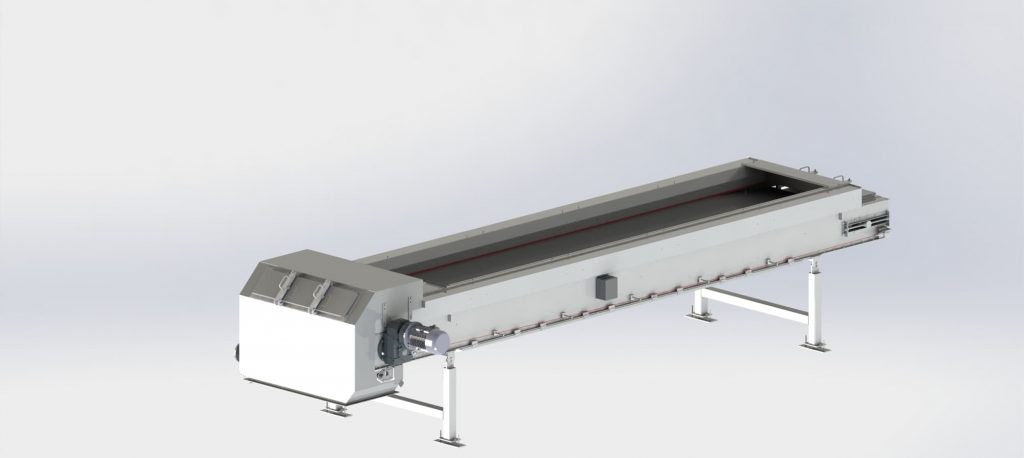

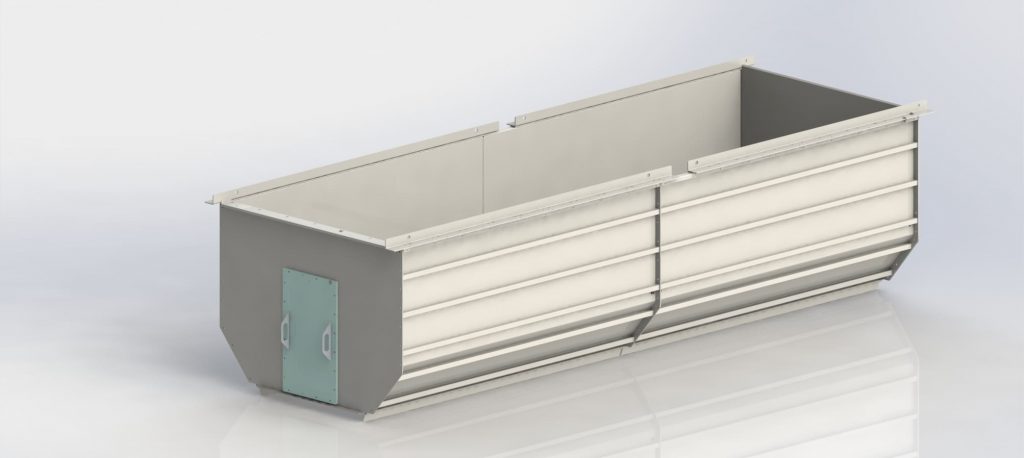

At first, fully automatic filter presses differ significantly from conventional filter presses. The basic architecture, the working principle and process technology are identical. Fully automatic filter presses are specifically designed for applications in which a continuous operation and fast cycle times are essential and therefore crucial. MSE fully automatic filter presses provide a high degree of automation while providing uninterrupted operation at the same time. The option of the simultaneous filter plate opening system, for example, helps to realise a particularly fast cake release reducing the cycle time to a minimum. The result is a high-speed filter press that allows increased production per unit area of filter. For this reason, these machines are used in applications with highly filterable products where high filtration speeds are required. These include, e.g. mining concentrates and residues.

OPTIONS FOR A FULLY AUTOMATIC FILTER PRESS

MSE also has several systems/plants for fully automated filter presses. This means that we have the right solution for all applications. All systems are self-monitoring and can be parametrised by the operator and optimised accordingly. In essence, there are 3 different systems. These include, e.g. the vibration device with eccentric beams and a simultaneous filter plate opening system, the vibrating device for individual filter plates and the spreader clamp/spreader cloth version.

FULLY AUTOMATIC FILTER PRESSES FROM MSE INCREASE PRODUCTIVITY AT THE SAME TIME REDUCING PERSONNEL COSTS

The operating time of a fully automatic filter press is 24/7. Although a daily check of the filter press is necessary. This only involves personnel costs of about 2 hours per day which is well below the value of a manually operated filter press. Please also read our detailed report in the process technology – filter presses for fully automatic operation.