At MSE Filterpressen, we don’t just build machines—we engineer solutions that redefine industry standards. Our filter presses are designed to tackle the most complex challenges, combining cutting-edge precision, long-term durability, and groundbreaking innovation.

Whether you need a fully customized system, modular expandability, or a solution built for extreme environments, MSE delivers filtration technology that does more than just work—it gives you a competitive edge. From energy-efficient operations to revolutionary automation, we don’t just create results—we transform your processes.

Cake-Forming Filtration with MSE

Unparalleled Performance in Solid-Liquid Separation

MSE filter presses stand at the forefront of mechanical solid-liquid separation, delivering tailored solutions for industries that demand excellence. Whether it’s for purification, by-product separation, resource recovery, or wastewater treatment, our technology offers:

- High dewatering efficiency

- Unmatched filtration precision

- Sustainable resource utilization

Designed with cutting-edge engineering, our press filters achieve industry-leading dry solids content and filtration purity, setting new performance benchmarks

Because your challenges require more than standard solutions—MSE delivers innovation.

Advantages & Features

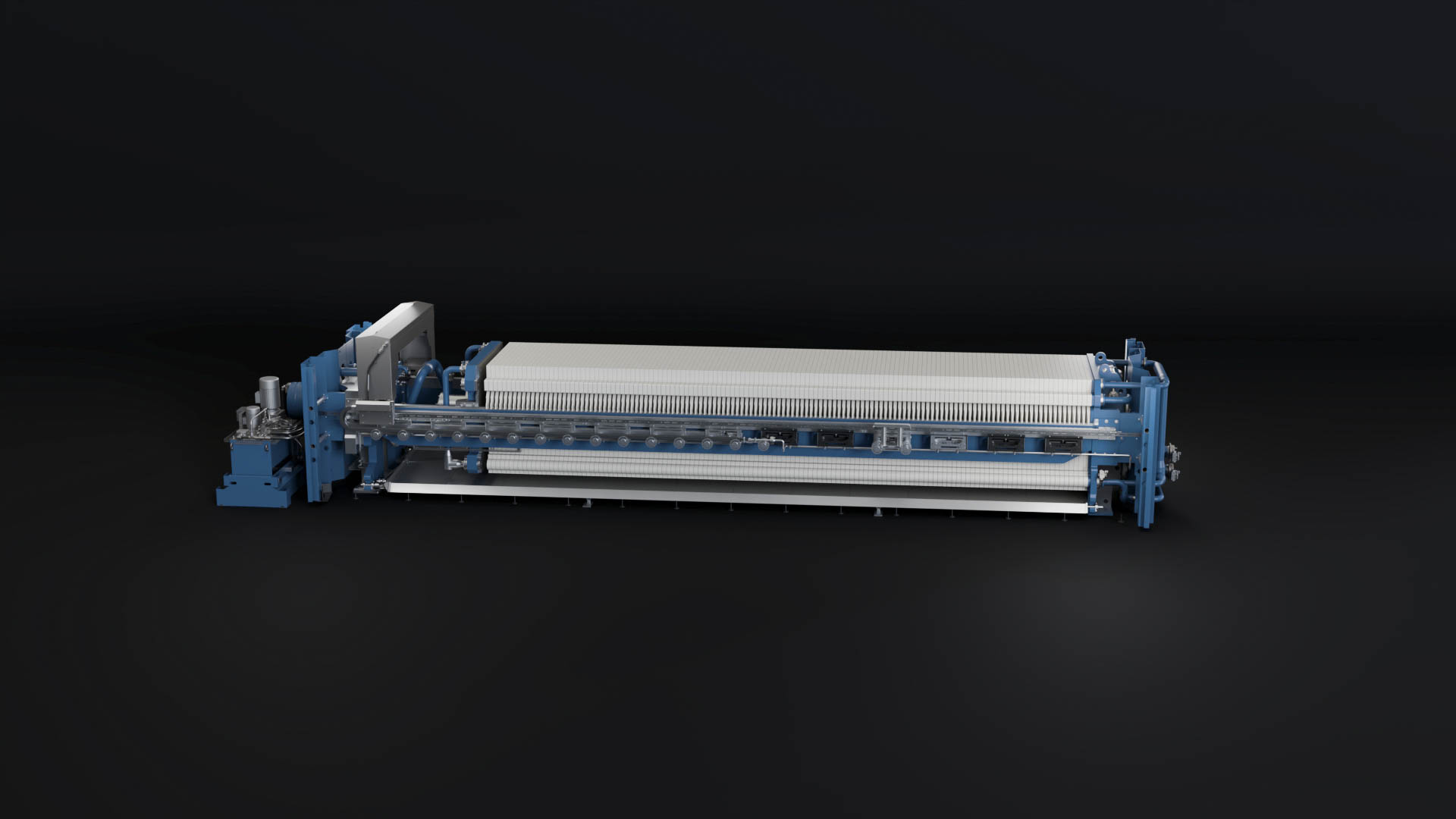

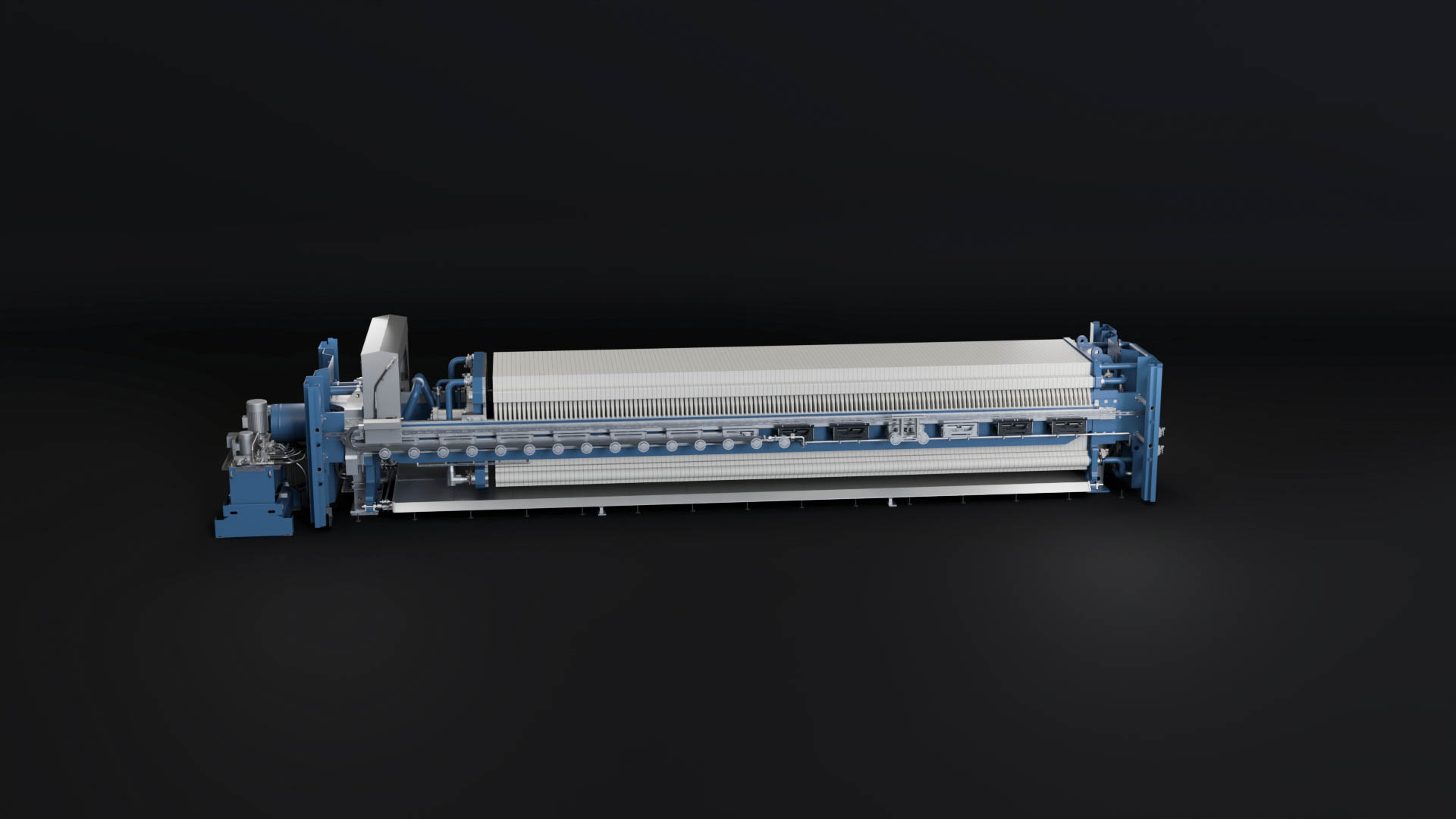

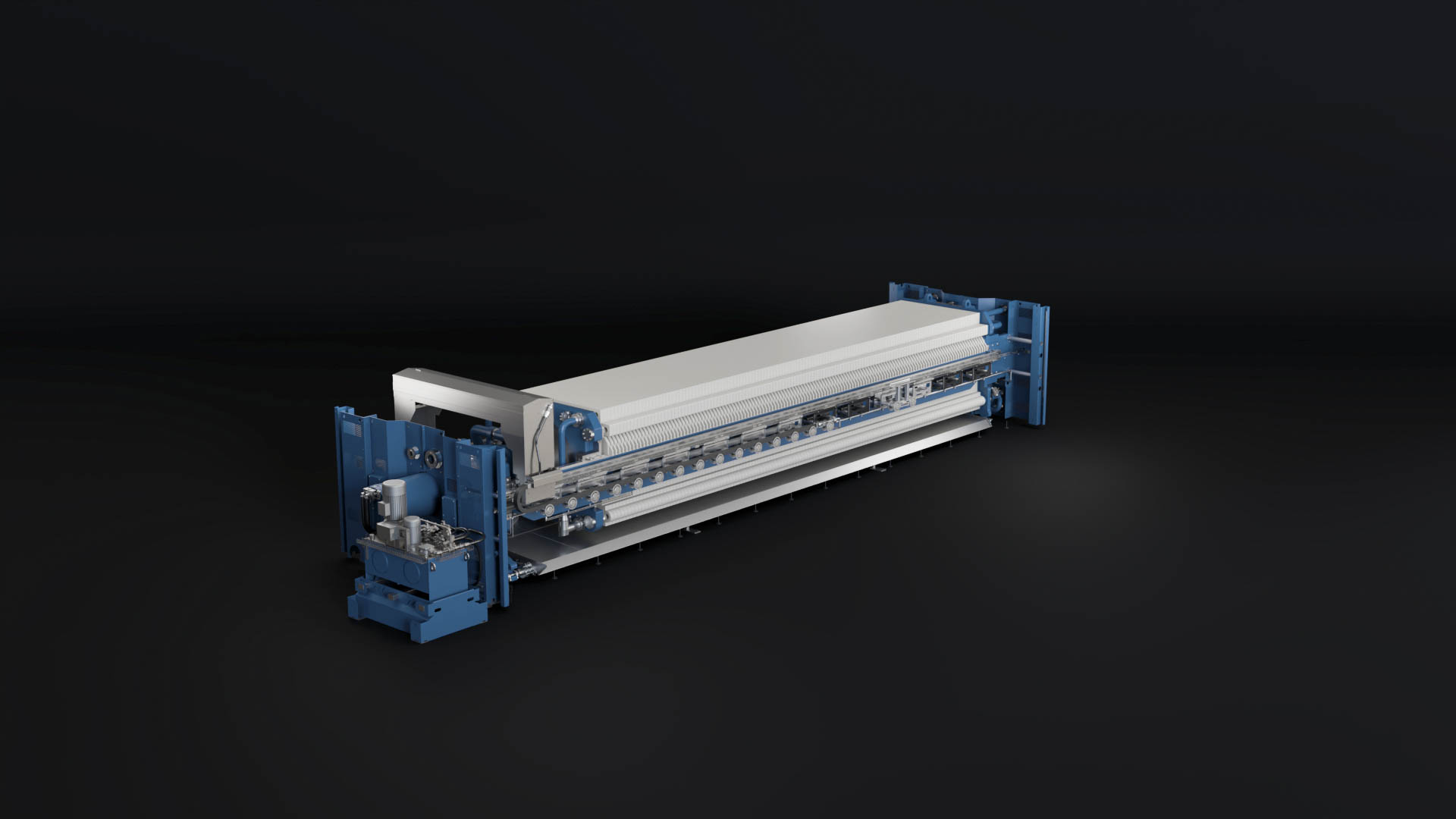

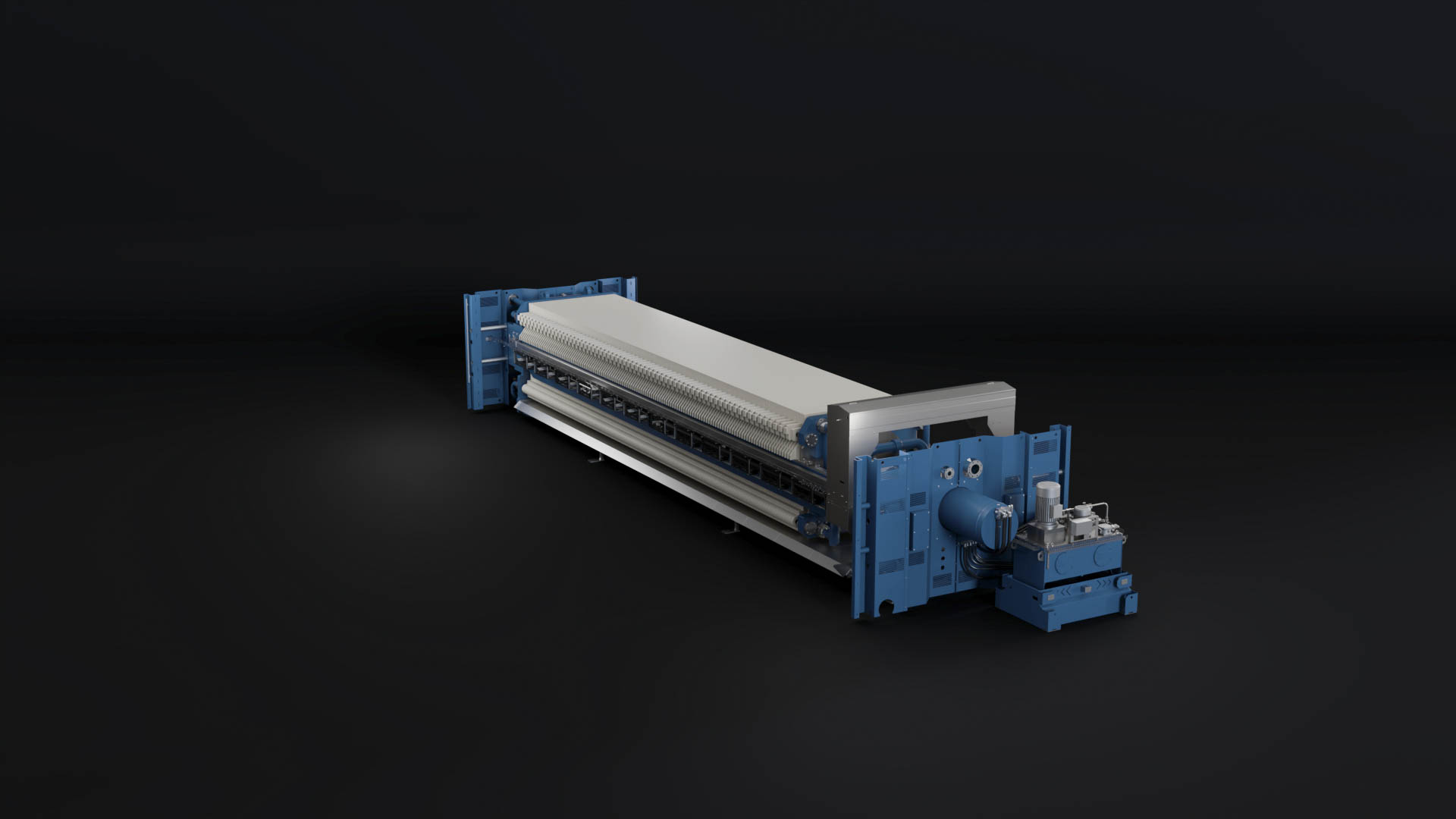

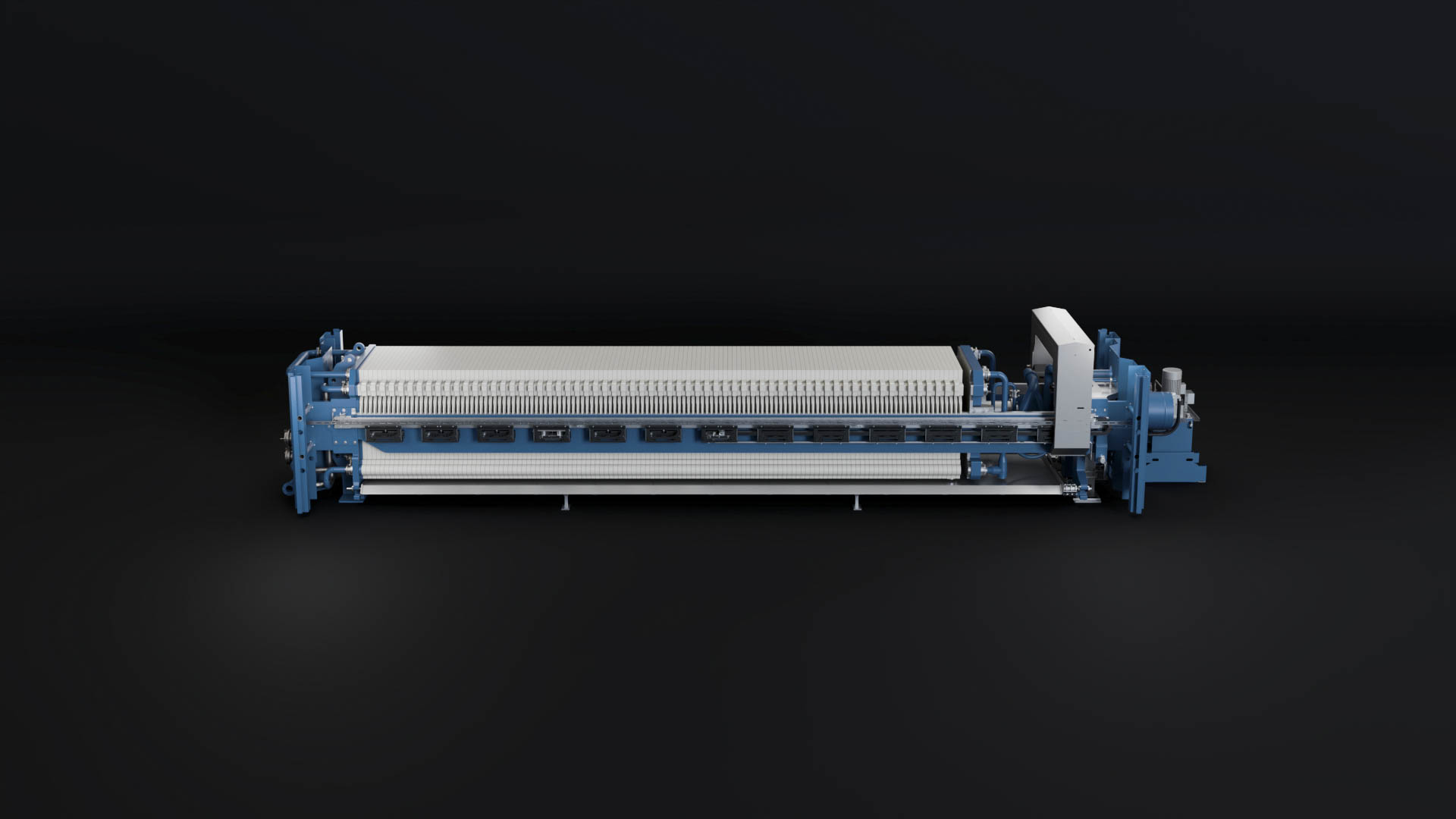

Chamber Filter Presses & Membrane Filter Presses by MSE

Our filter presses aren’t just another industrial product—they’re the key to pushing boundaries in your sector.

Why? Because at MSE, we don’t just build machines—we engineer success.

Modular Filter Press Design

Smart Engineering for Maximum Efficiency

MSE filter presses feature a modular design, allowing for scalable, high-performance solutions. The robust steel frame includes a feed stand, hydraulic stand, side beams, and a movable pressure plate, ensuring precise fixation of filter plates and cloths.

- Single-cylinder hydraulic technology reduces complexity, increases reliability, and minimizes maintenance.

- Compact side beam construction enables easy handling and installation.

- Modular design ensures cost-efficient solutions without sacrificing quality.

The side-beam design reduces overall weight compared to overhead beam filter presses. This significantly lowers structural loads and leads to considerably reduced investment costs in building infrastructure.

Precision-Engineered Filter Elements

Filter Cloths & Plates – Performance Redefined

MSE custom-engineers filter cloths and plates tailored to your process needs. Whether it’s cake washing, core blowing, or real-time moisture measurement, every element is optimized for efficiency.

- Premium materials such as copolymers, aluminum, stainless steel, and carbon fiber ensure chemical and mechanical resilience in extreme conditions.

- Precise separation, uniform cake formation, and minimal residual moisture maximize efficiency.

- Proprietary MSE developments redefine quality and functionality in filtration.

Modular Filter Press Options

Intelligent Automation & Seamless Integration

Our mechanical and automation modules turn your filter press into a high-performance, fully optimized system. From automatic plate shifting to intelligent cake discharge and real-time monitoring, every feature is designed to enhance efficiency and eliminate downtime.

- Advanced automation ensures peak performance at every step of filtration.

Flexible Filtration Configurations

The Right Filter Press for Every Application

MSE filter presses are designed for adaptability, offering tailored solutions for a diverse range of industries. The ideal press type and format is determined by your medium, process requirements, and filtration cycle.

Our filter presses separate solids from µm to mm, whether in enzyme production, sewage sludge disposal or other demanding applications. Developed for the toughest challenges. Tailor-made for you.

- Handling solid separations from microns to millimeters, in industries like enzyme production and sludge dewatering.

- Available in sizes from 250 mm to 2500 mm, with pressures up to 30 bar, ensuring maximum process reliability.

- Filtration Volume: 2 l to 25,000 l

- Filter Area: 0.5 m² to 1500 m²

Protective Coatings & Surface Finishes

Durability Meets Design

Longevity starts with protection. MSE filter presses are treated with high-performance coatings for maximum resistance against wear and environmental exposure.

- Standard coatings: 220 µm (C4-M) for structural parts, 160 µm (C3) for add-on components.

- For extreme environments: Optional C5 coatings, stainless steel cladding or rubber linings.

- Standard color: RAL 7011 (Iron Gray), with custom RAL colors available.

Smart Control Systems

Intelligent Automation & Precision Control

MSE’s in-house engineered control systems are designed for maximum process efficiency, safety, and precision.

- Seamless integration with industrial control networks via PROFINET or PROFIBUS interfaces.

- User-friendly touch panels provide clear visualization and effortless process control.

- Customizable and scalable—built to evolve with your operations.

Technical Specifications

MSE Filter Element Technologies in Comparison

Choosing between a chamber filter press, a membrane filter press, or a heated filter press depends on the specific demands of your process. While chamber filter presses are valued for their simplicity and cost-effectiveness, membrane filter presses stand out for their higher efficiency, shorter cycle times, and superior dewatering performance. At MSE Filterpressen, we provide customized solutions that are meticulously engineered to meet your exact requirements, ensuring maximum efficiency, reliability, and cost-effectiveness.

01

Core Design

- Chamber Filter Press:

Built with fixed filter plates featuring integrated chambers, covered by filter cloths. The dewatering process relies solely on pressure-driven filtration. - Membrane Filter Press:

Functions similarly to a chamber press, but includes flexible membranes that enable an additional mechanical squeezing step, significantly reducing moisture content in the filter cake. - Heated Filter Press:

Similar in design to chamber or membrane filter presses (depending on configuration), but equipped with internal channels within the filter plates to enable additional thermal drying.

02

Dewatering Mechanism

- Chamber Filter Press:

Filter cake formation is achieved exclusively through pump pressure and filtration, which may result in longer cycle times and limited moisture removal. - Membrane Filter Press:

Incorporates additional mechanical compression, leading to faster dewatering, increased efficiency, and drier filter cakes. - Heated Filter Press:

In addition to pressure filtration, heated plates (comprising chamber or membrane elements) further dry the filter cake, enabling higher dry solids content. Optionally, the cake can be mechanically compressed using membrane elements before thermal drying.

03

Achievable Dry Solids Content

- Chamber Filter Press:

Achieves dry solids levels of 60% to 80%, depending on suspension properties and process conditions. - Membrane Filter Press:

Capable of reaching up to 98% dry solids content, even in partially filled chambers, making it ideal for high-demand applications. - Heated Filter Press:

Achieves the highest possible dry solids content—depending on sludge composition and dewatering characteristics.

04

Process Adaptability

- Chamber Filter Press:

Suitable for low-to-moderate solid concentrations or applications where standard dewatering efficiency is sufficient. Designed to handle feed pressures up to 30 bar, which effectively reduces residual moisture. - Membrane Filter Press:

The added mechanical membrane compression (up to 30 bar) enhances process flexibility, providing superior moisture reduction and adaptability to varied operational conditions. - Heated Filter Press:

Ideal for processes with demanding dry solids requirements. Optional feed or membrane pressure (up to 30 bar) enhances adaptability and reduces cycle times.

05

Cycle Time & Throughput

- Chamber Filter Press:

Longer processing times, as the filtration cycle depends entirely on pump pressure and filtrate flow rate. - Membrane Filter Press:

Accelerated moisture reduction due to mechanical cake compression, resulting in shorter cycles and increased overall throughput. - Heated filter press:

The additional thermal drying step extends the overall cycle compared to pure membrane filtration, but significantly increases the achievable dry substance content.

However, if the process is optimally designed, the heated filter press can reduce overall process times – especially if downstream thermal drying stages (e. g. belt dryers) can be eliminated or reduced in size.

06

Cost & Maintenance Considerations

- Chamber Filter Press:

Lower upfront and operational costs due to its simpler design—no membranes or additional pressure systems are required. The straightforward mechanics lead to lower maintenance efforts and costs. - Membrane Filter Press:

Higher initial investment and operating costs, as additional membrane components and compression systems require extra energy or air pressure. However, enhanced efficiency and shorter cycle times contribute to long-term cost savings. - Heated Filter Press:

Highest capital and operating costs among the three filter element technologies due to more complex mechanics, specialized filter plates, and the required heating station. Additional energy is needed for the thermal drying process.

07

Application Benefits

- Chamber Filter Press:

Budget-friendly solution for applications where standard dewatering efficiency meets process requirements. Ideal for stable filtration processes with moderate throughput needs. - Membrane Filter Press:

Preferred for industrial applications requiring maximum dewatering performance and efficiency. Faster cycle times and reduced pump wear lower long-term operational costs, especially in abrasive or high-demand environments. - Heated Filter Press:

Ideal for industrial applications with extremely high dry solids requirements or when purely mechanical dewatering is insufficient due to the filter cake’s dewatering behavior.

Modules for Maximum Performance

MSE Filterpressen offers fully customizable modules—from automated plate transport systems to advanced cake treatment solutions—to ensure maximum efficiency, reliability, and process control.

Custom System Peripherals

From robust platforms and intelligent conveyor systems to custom-built containers—MSE provides fully integrated solutions that seamlessly enhance your filter press operations.

Detailed consulting & innovative engineering

We implement your requirements quickly and precisely! With our in-house development and production, we work with you to create tailor-made solutions. We master even complex challenges! See for yourself.

Contact

Get in Touch Speak with Our Experts

How can we support you? We’re here for you throughout the entire

lifecycle of your filter press.