Filter presses versus centrifuges in comparison

Filter presses are mechanical solid-liquid separation units which are used in the field of pressure filtration of suspensions. During discontinuous filtration, the actual separation effect takes place through a filter cake, which forms on the filter cloth. As one of the oldest filter units, the filter press is the most important and efficient process pressure filter. Especially when it comes to the highest level of filtration efficiency and maximum degree of dewatering of various filter media. Filter presses are widely used in industrial production for the separation of sludges, chemical substances and petroleum. Also, in the field of municipal waste water treatment. Filter presses have also been making a major contribution to the separation of solid-liquid substances in the production of raw materials for decades, for example for the pharmaceutical, chemical and petrochemical industries as well as the food and mineral industries.

Centrifuges are also units for mechanical solid-liquid separation of suspensions. When centrifuging, the separation of the medium takes place not by using filter agents (filter plates and filter cloths) but by exploiting the centrifugal force occurring in uniform circular motion in contrast to filtration with filter presses. This centrifugal force which is caused by inertia is generated in a rotating is generated in a rotating drum, the centrifuge, where high acceleration forces can be achieved. Centrifuges are used in the dewatering and thickening of sewage sludge. Centrifuges are also used for solid-liquid separation in other industrial applications such as, e.g. the food industry and oil and fat production.

Starting situation and task:

In this project, separation units (the filter press or the centrifuge) are compared to see which achieves the better result with respect to specified customer requirements in the case of solid-liquid separation based on the same basic suspension. The range of requirements includes a minimum throughput, a required maximum residual moisture in the filter cake, the amount of depositable substances in the filtrate as well as the type of conditioning of the suspension. The starting medium for this comparison is a mineral suspension present after separation in a sewage canal drift. This is very sticky, because it is permeated with clay and marl. The clay-marl suspension is conditioned for the solid-liquid separation.

Requirements:

-

- Throughput > 8 tons TR/h

-

- Residual moisture in the filter cake < 40%

-

- Depositable materials in the filtrate < 20 mg/l

-

- Conditioning with polymer (do not use lime milk), if necessary use small amounts of a precipitant.

Result:

The final result is tabulated below. The filter press meets all specified requirements or exceeds these.

To sum up: The filter press once again demonstrates its outstanding performance in the field of mechanical solid-liquid separation compared to the centrifuge.

Chamber filter press Centrifuge

throughput [T/TR/h] 10 5

Residual moisture [%] < 35 < 50

DM substance [%] > 65 > 50

Depositable material Filtrate [mg/l] < 20

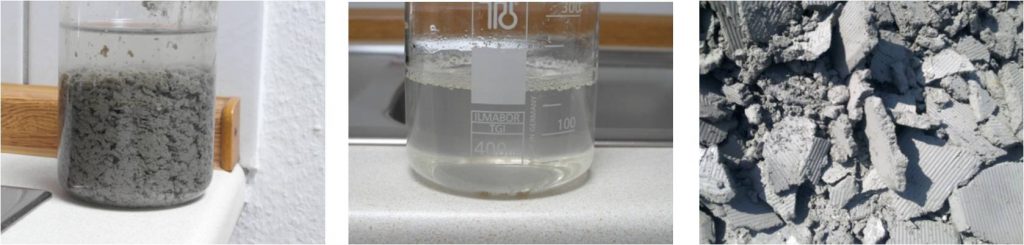

Suspension Centrate from the centrifuge Solid discharge from the centrifuge

Flocculated suspension Filtrate from filter press Solid discharge from the filter press

Du musst angemeldet sein, um einen Kommentar abzugeben.