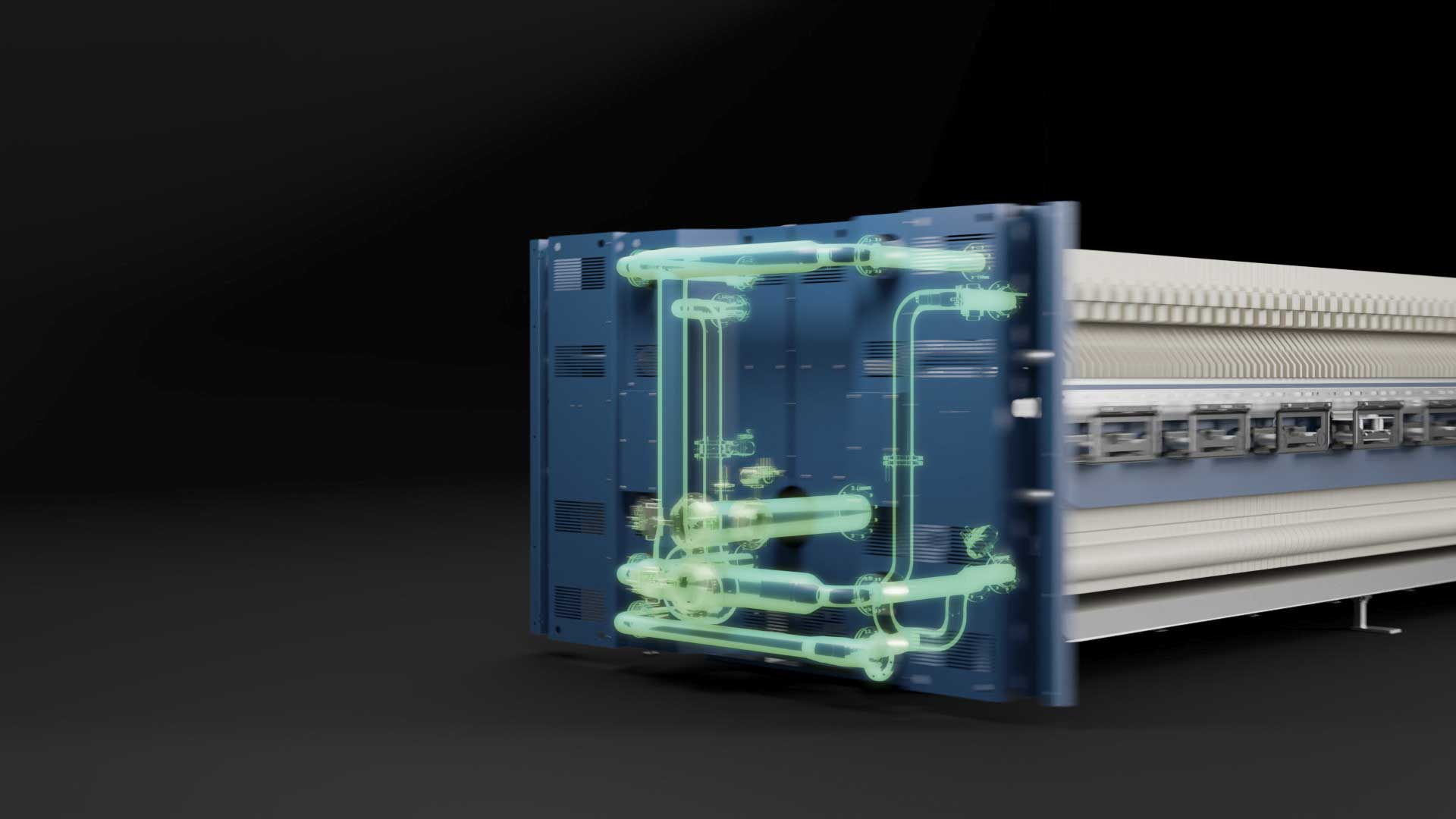

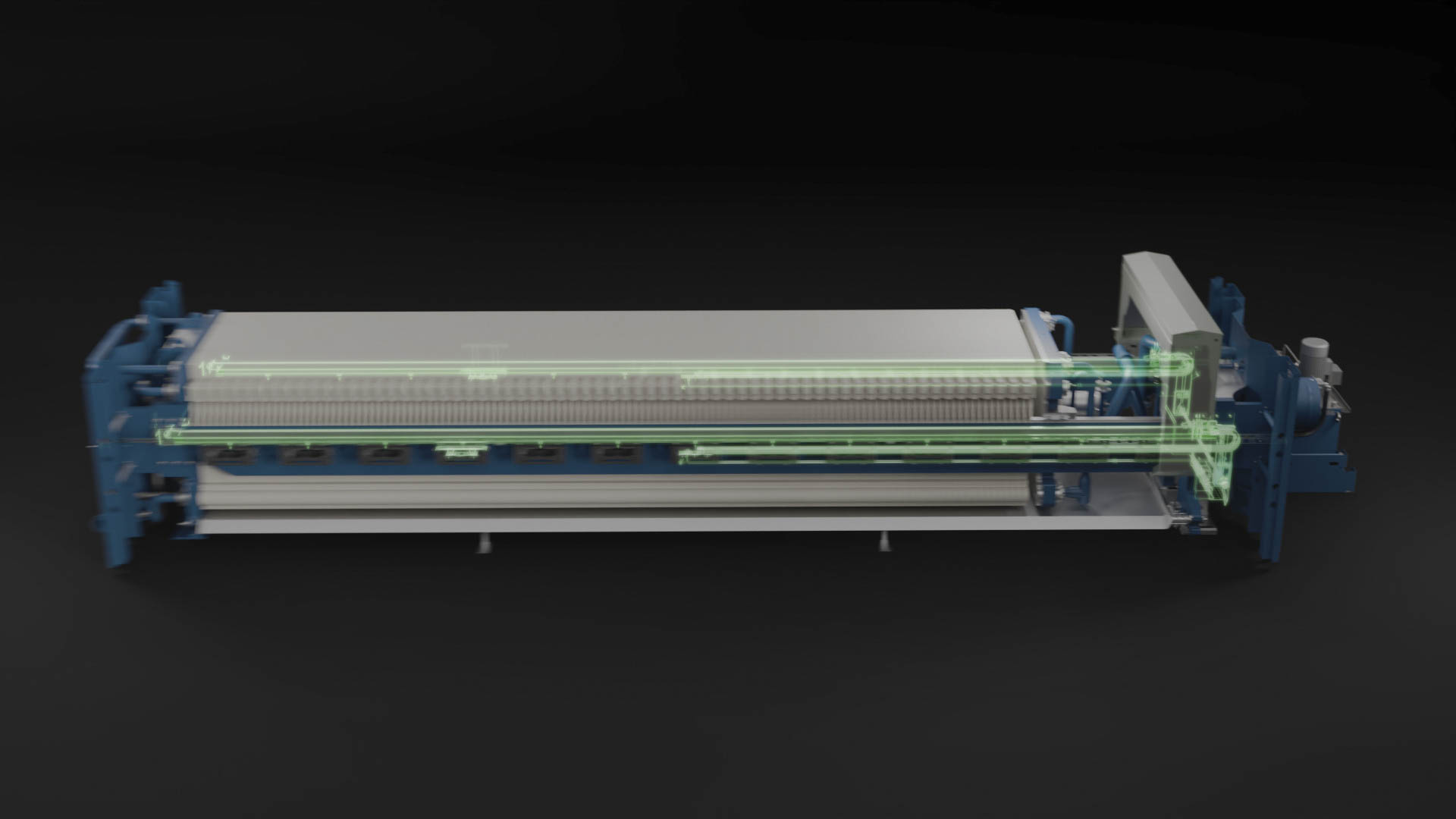

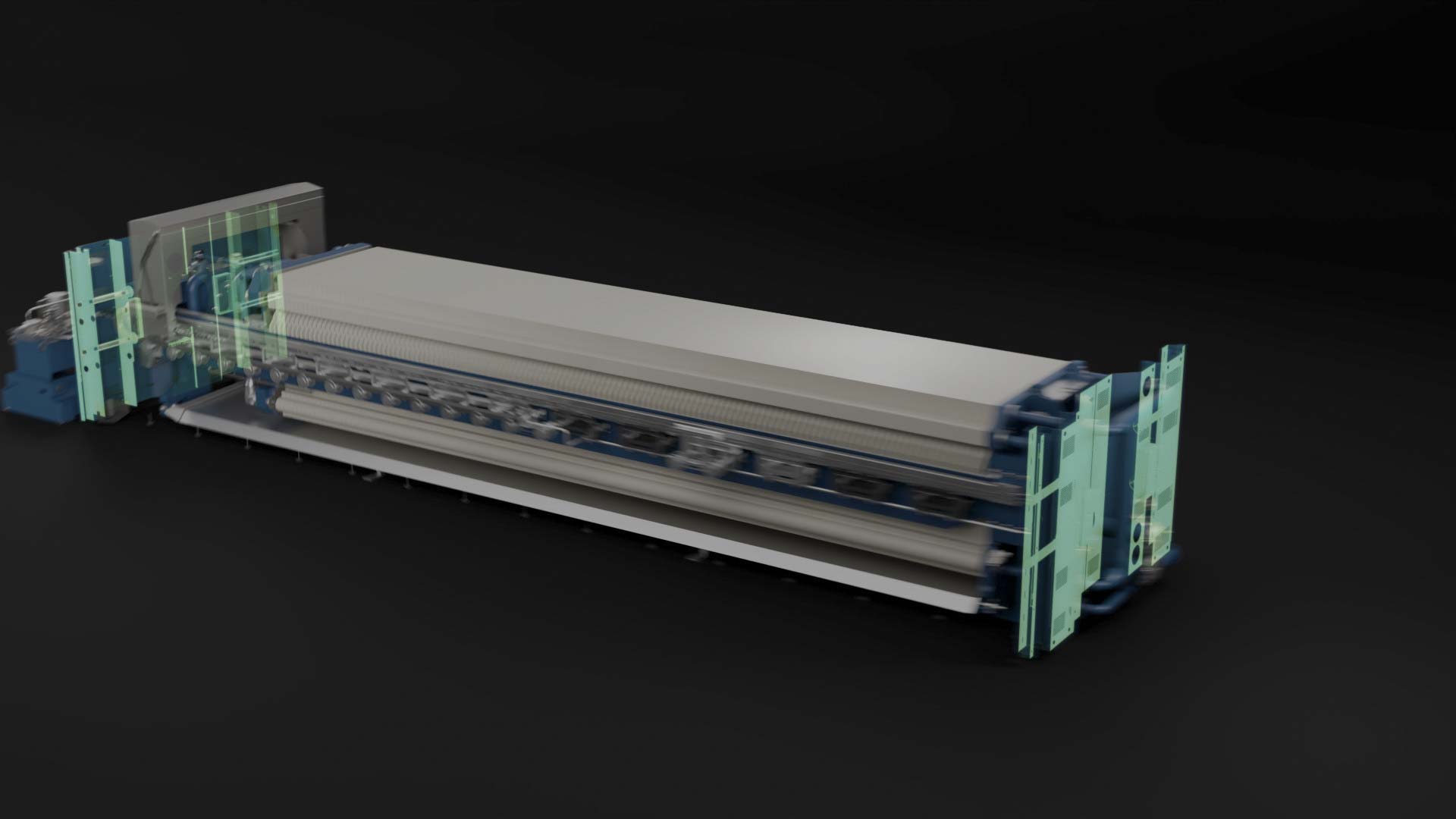

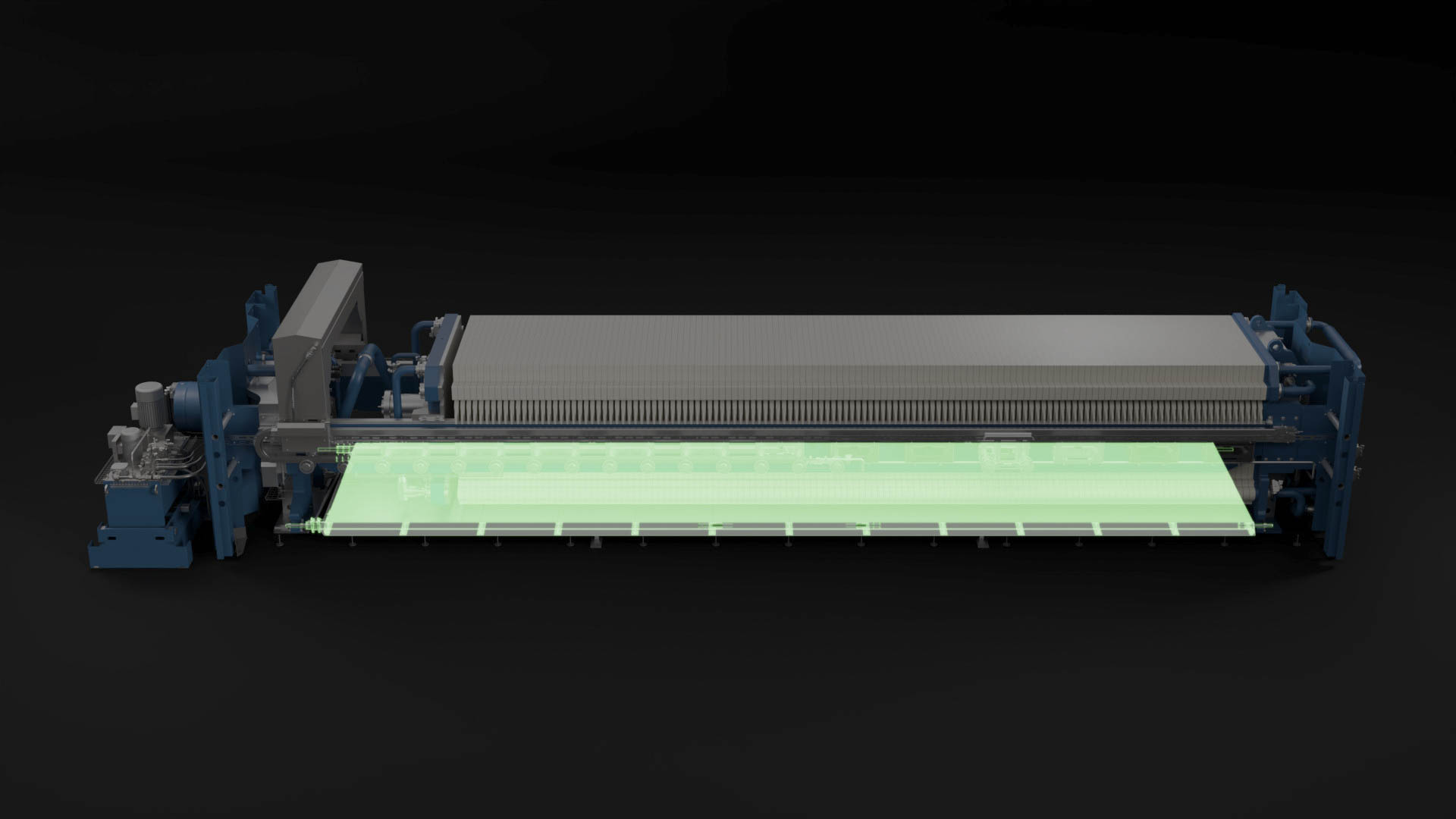

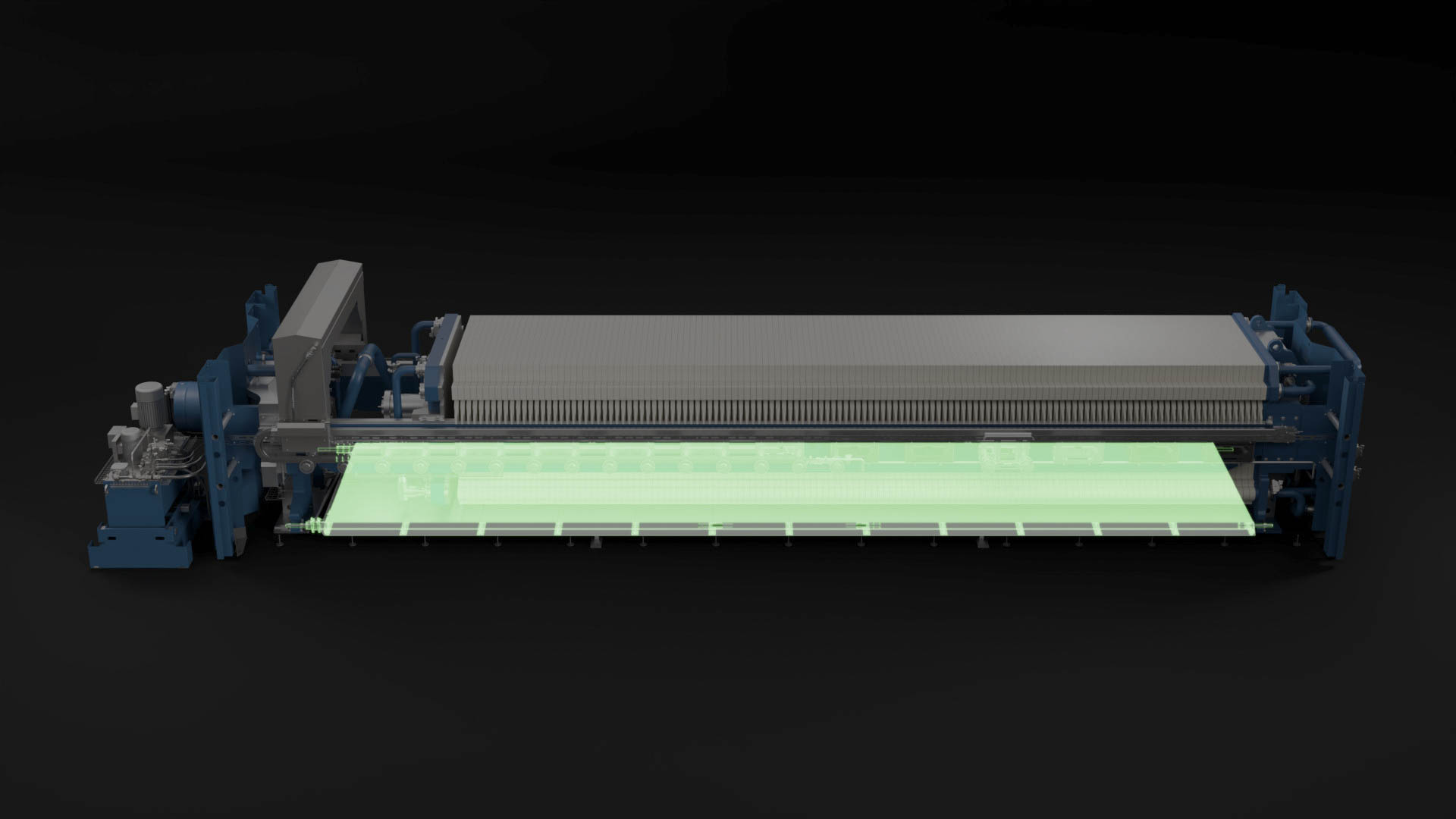

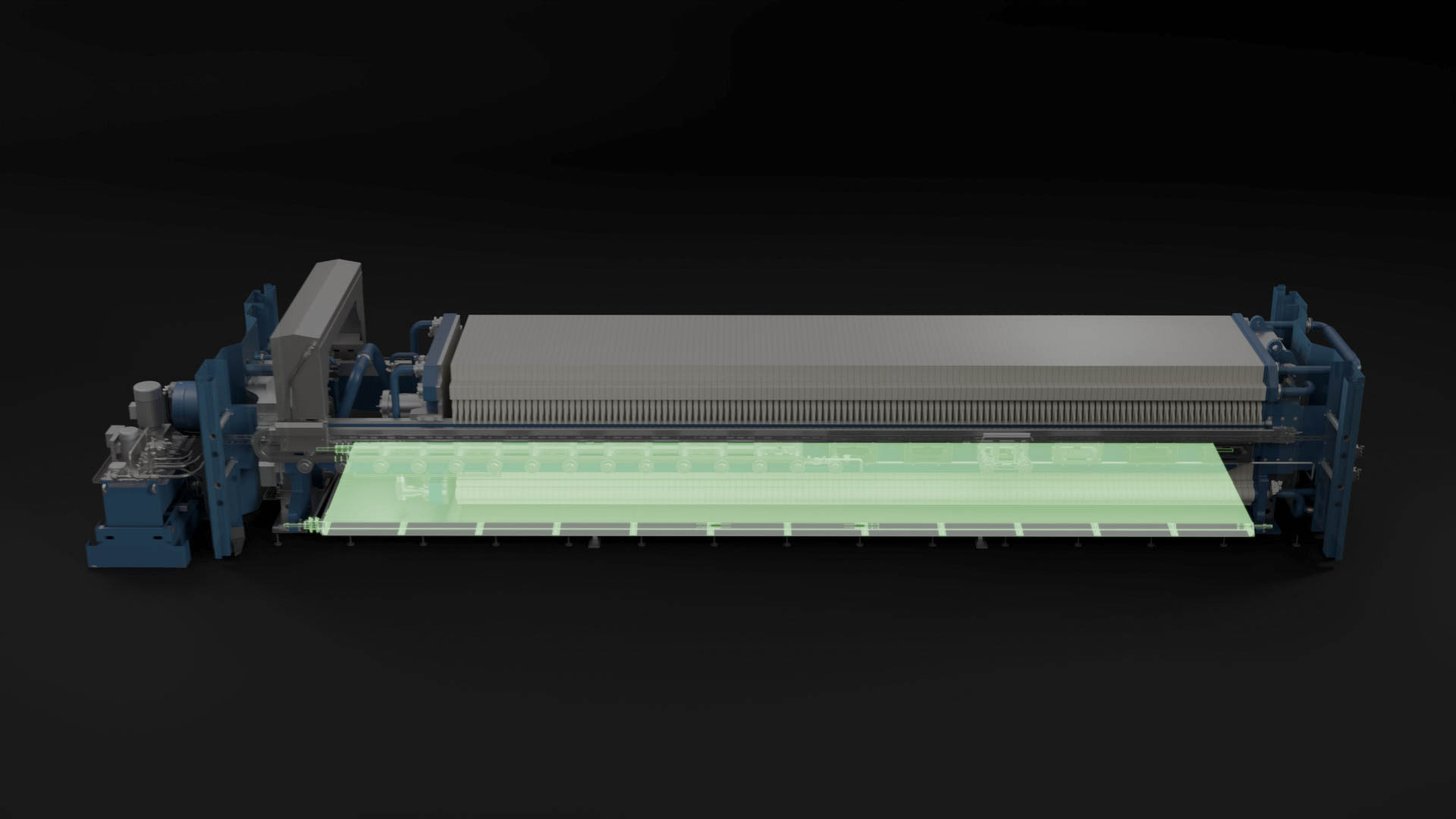

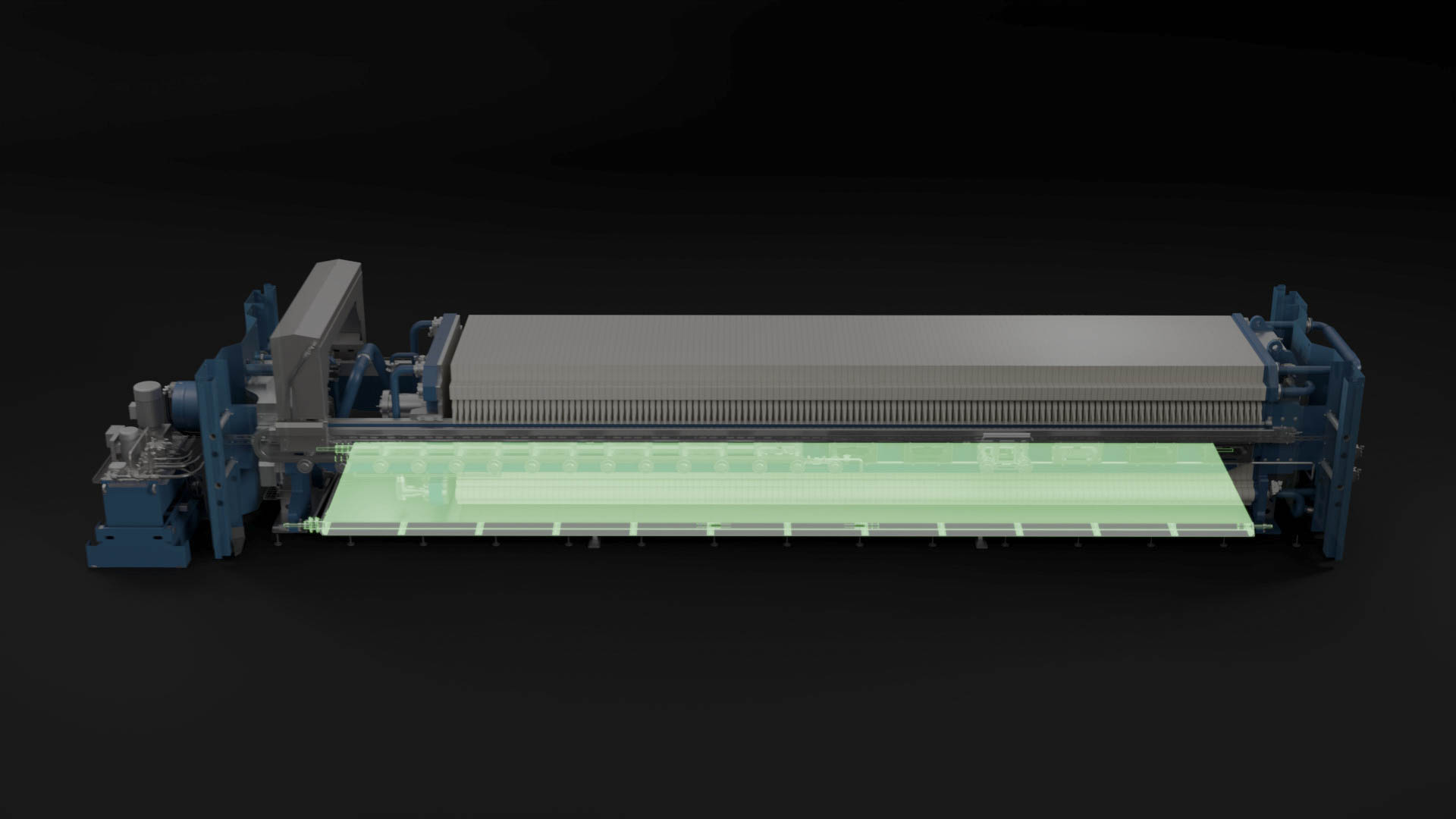

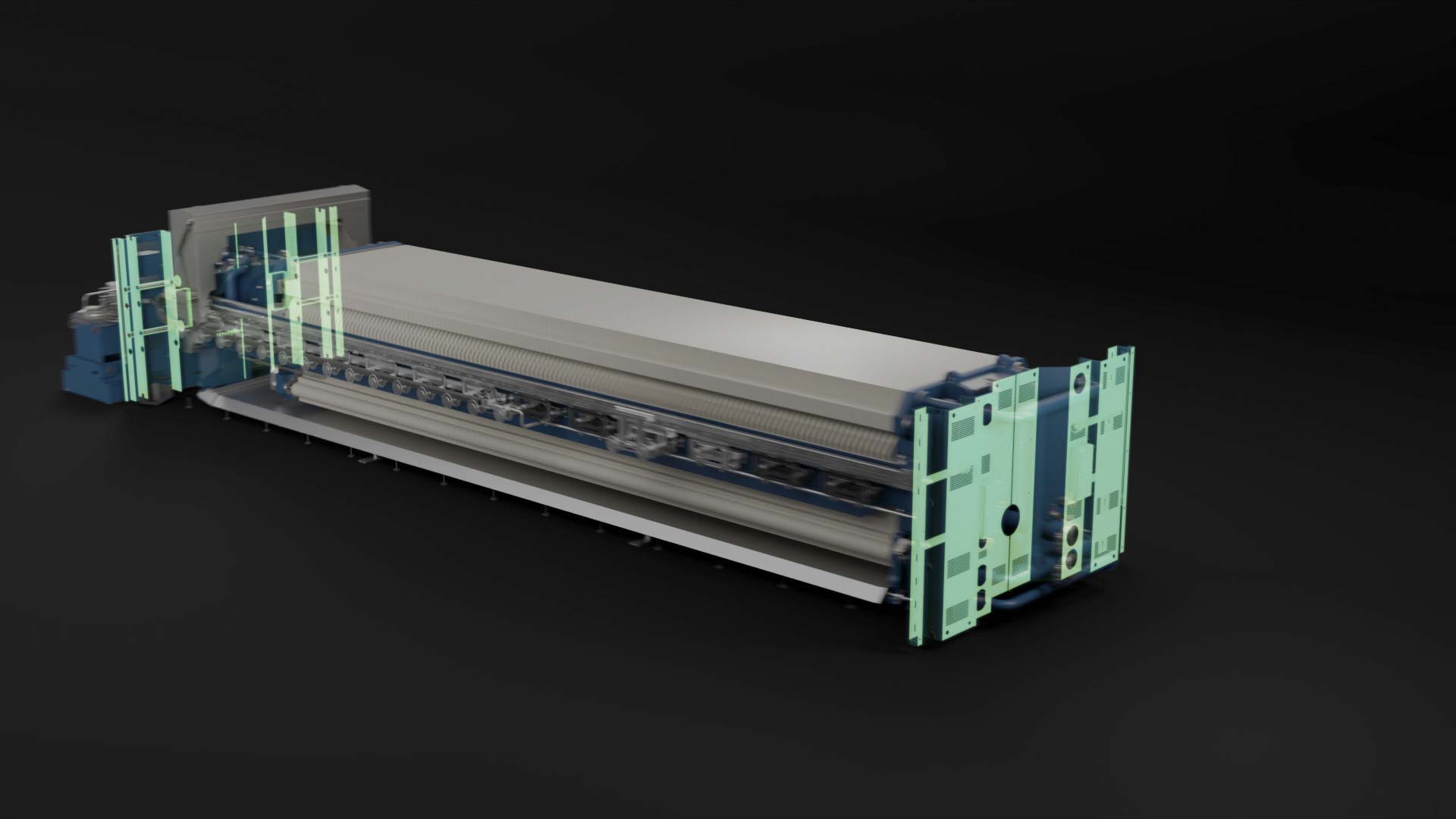

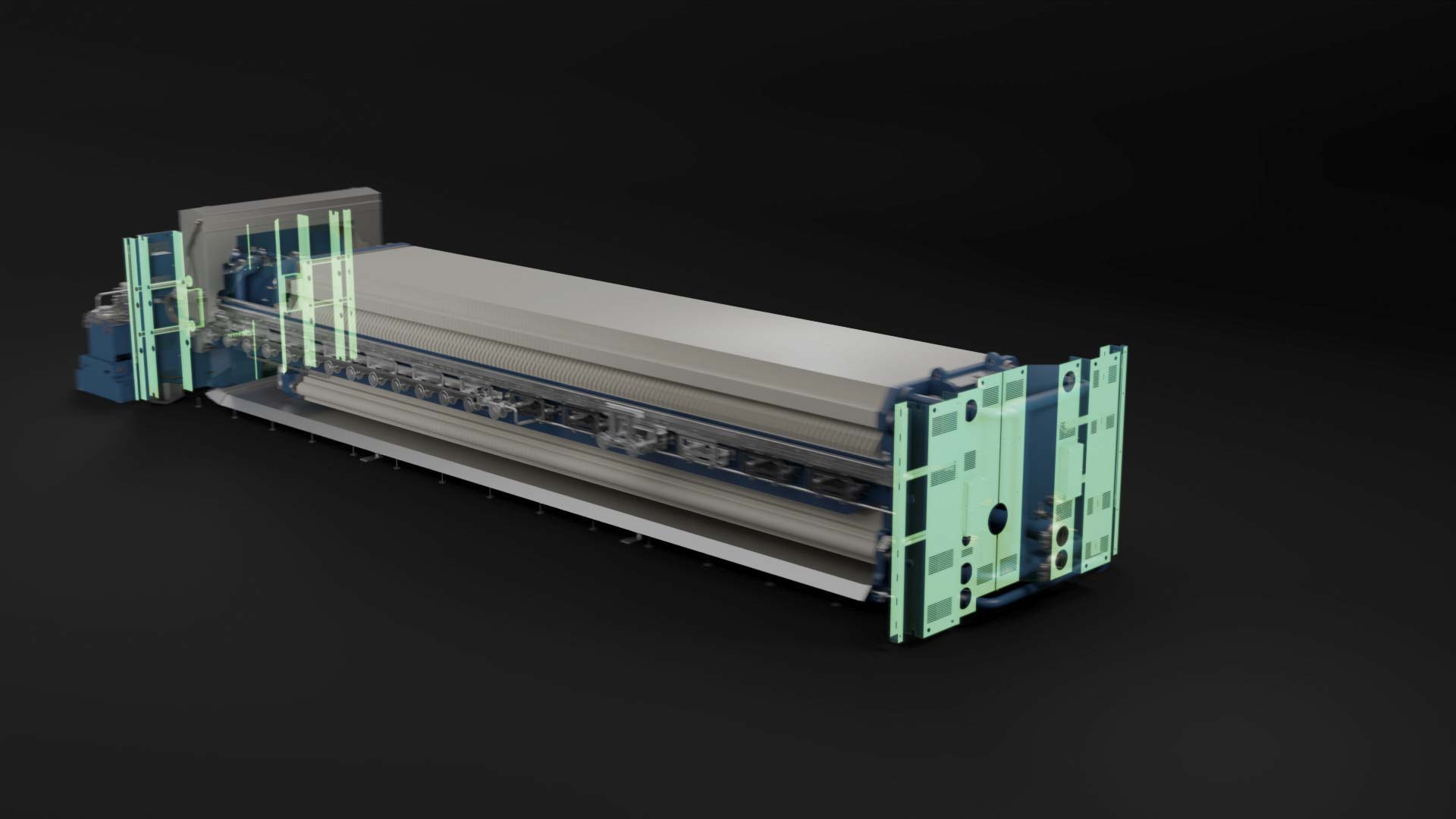

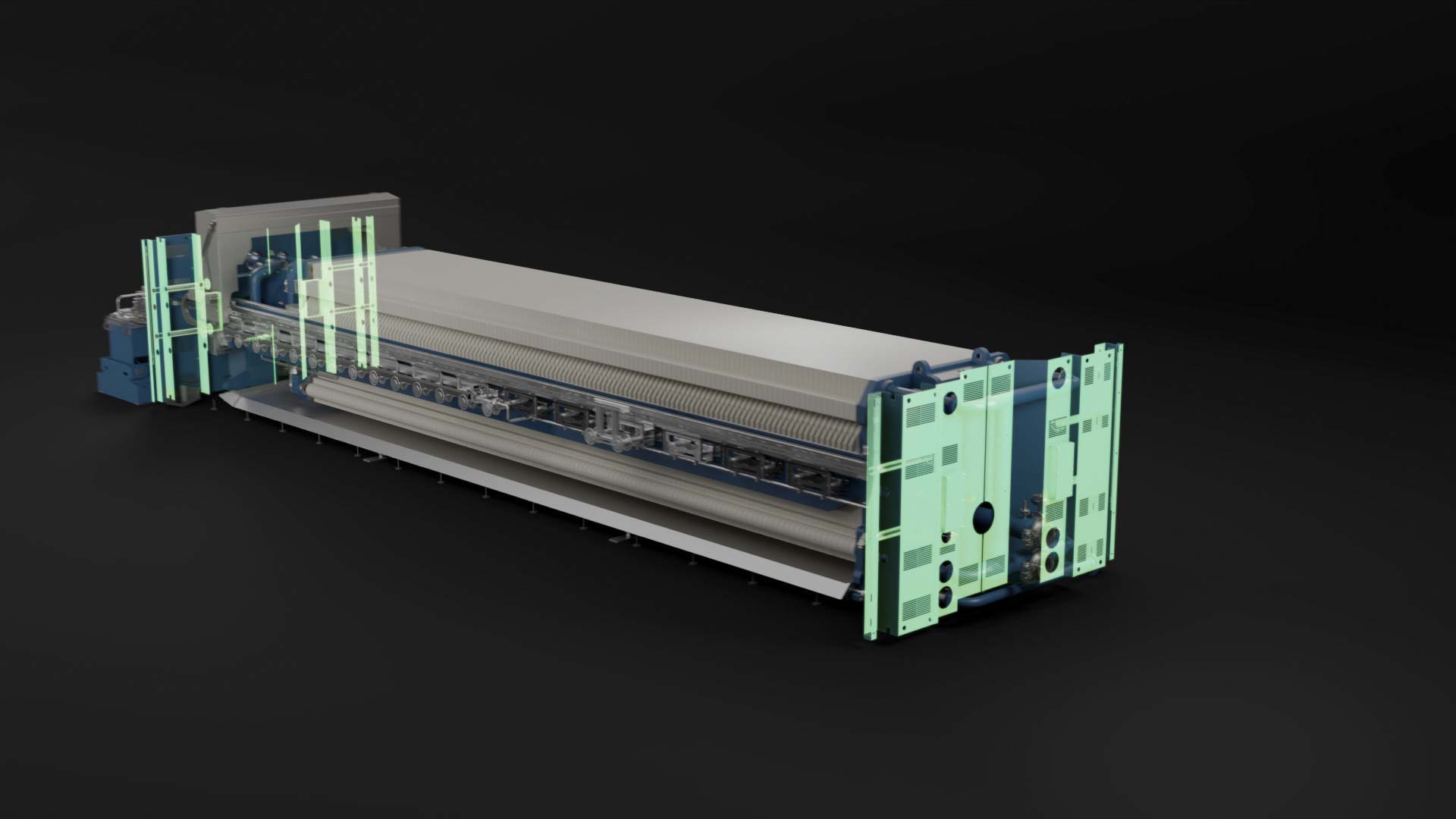

MSE filter press modules are designed for seamless adaptability, transforming your filtration system into a high-performance, fully optimized solution. With state-of-the-art modular configurations that align precisely with your filtration process requirements, our tailored solutions guarantee maximum performance and process stability.

At MSE, customization goes beyond technology—we work with you to create a solution that not only meets your current needs but is also future-proof. For us, efficiency isn’t just a goal—it’s the standard.

Advanced System Technologies

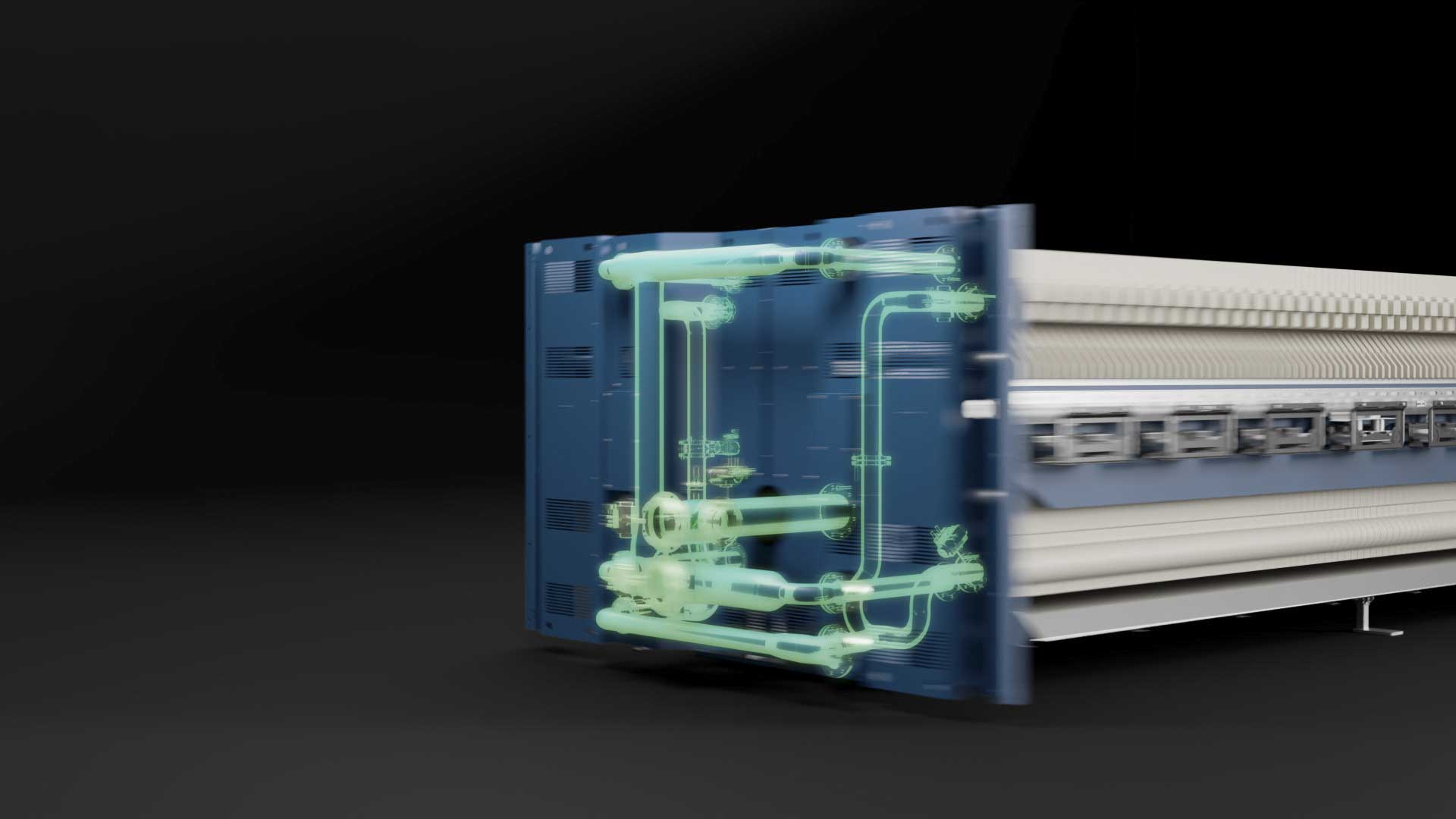

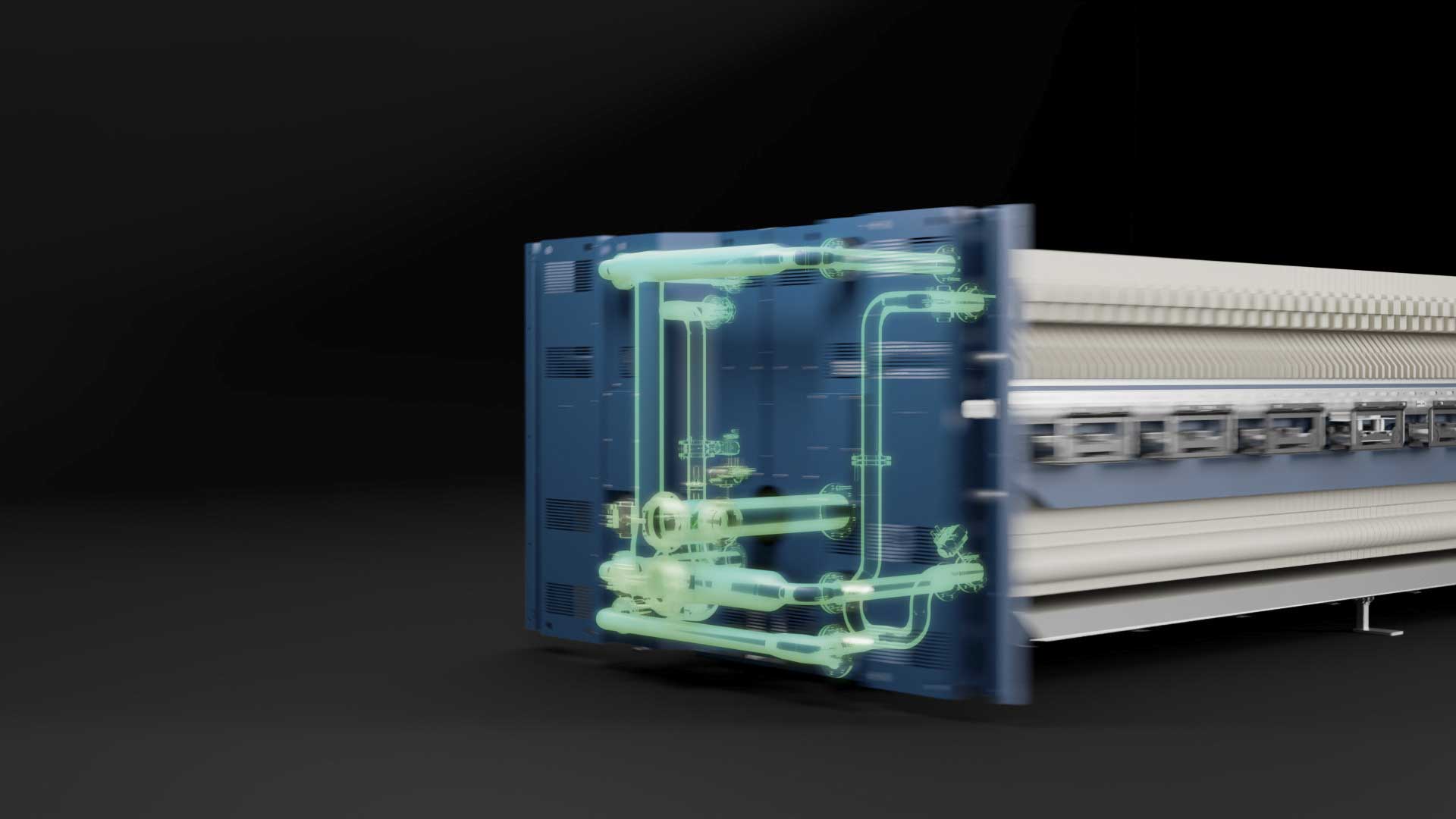

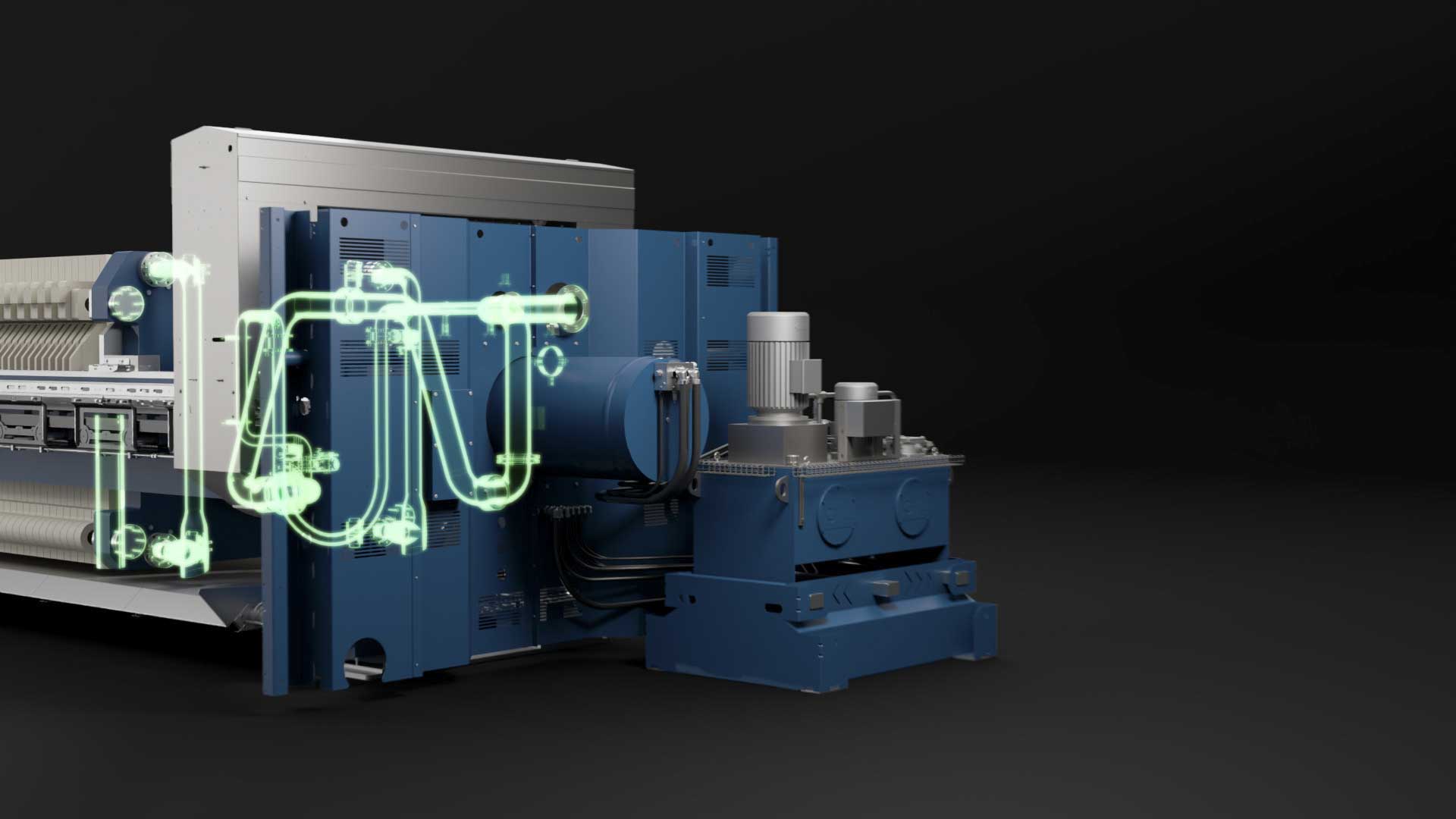

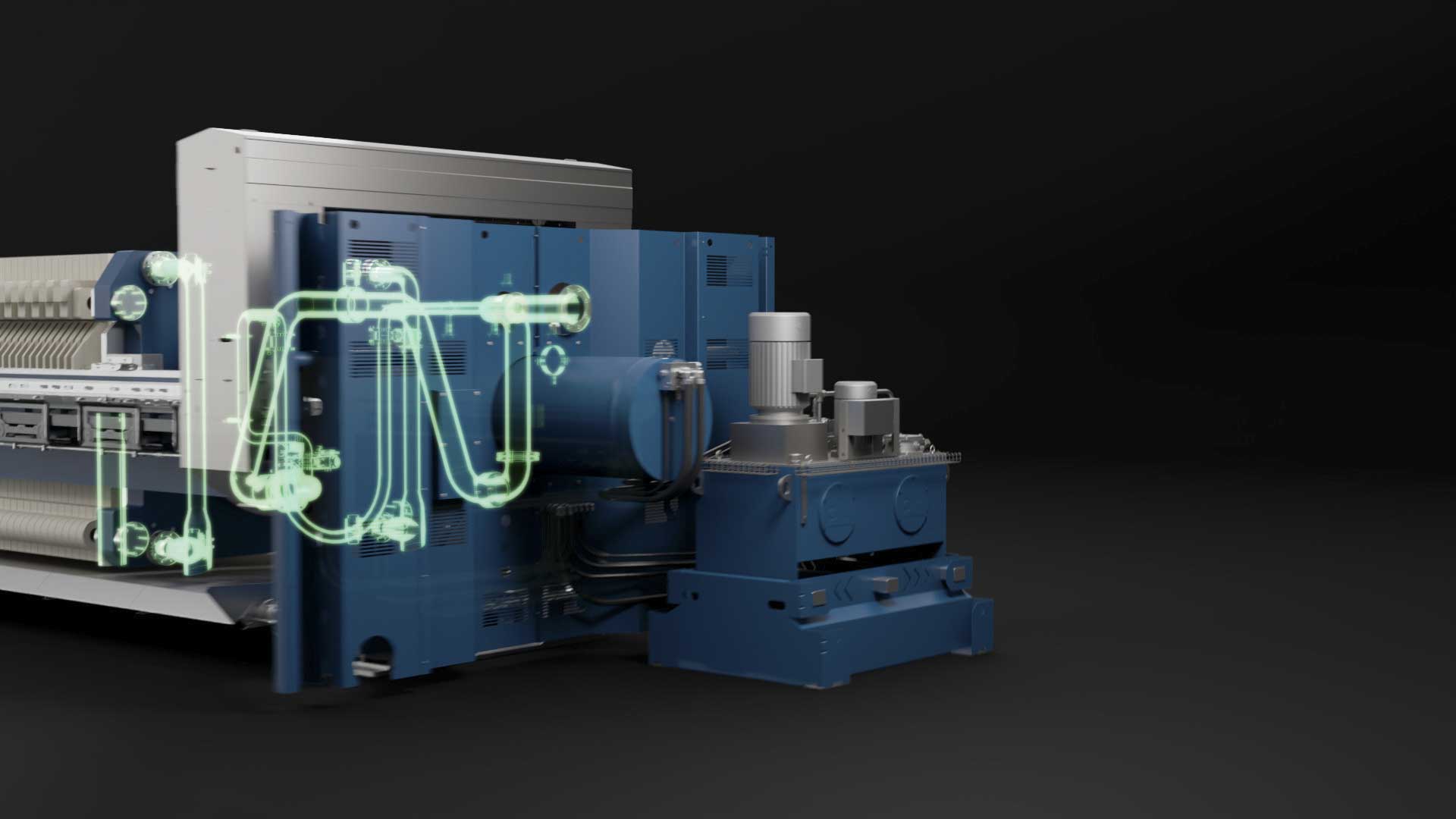

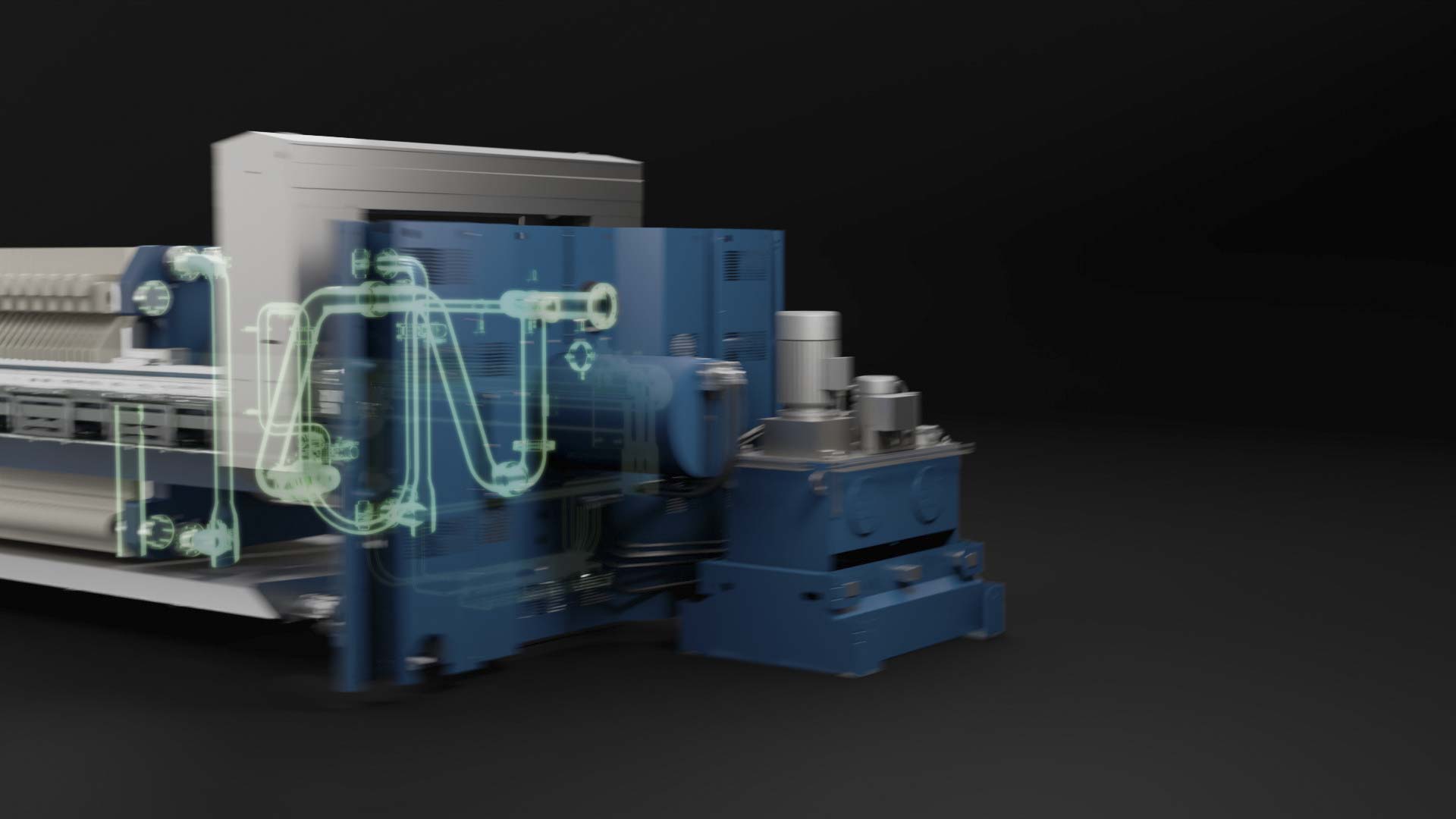

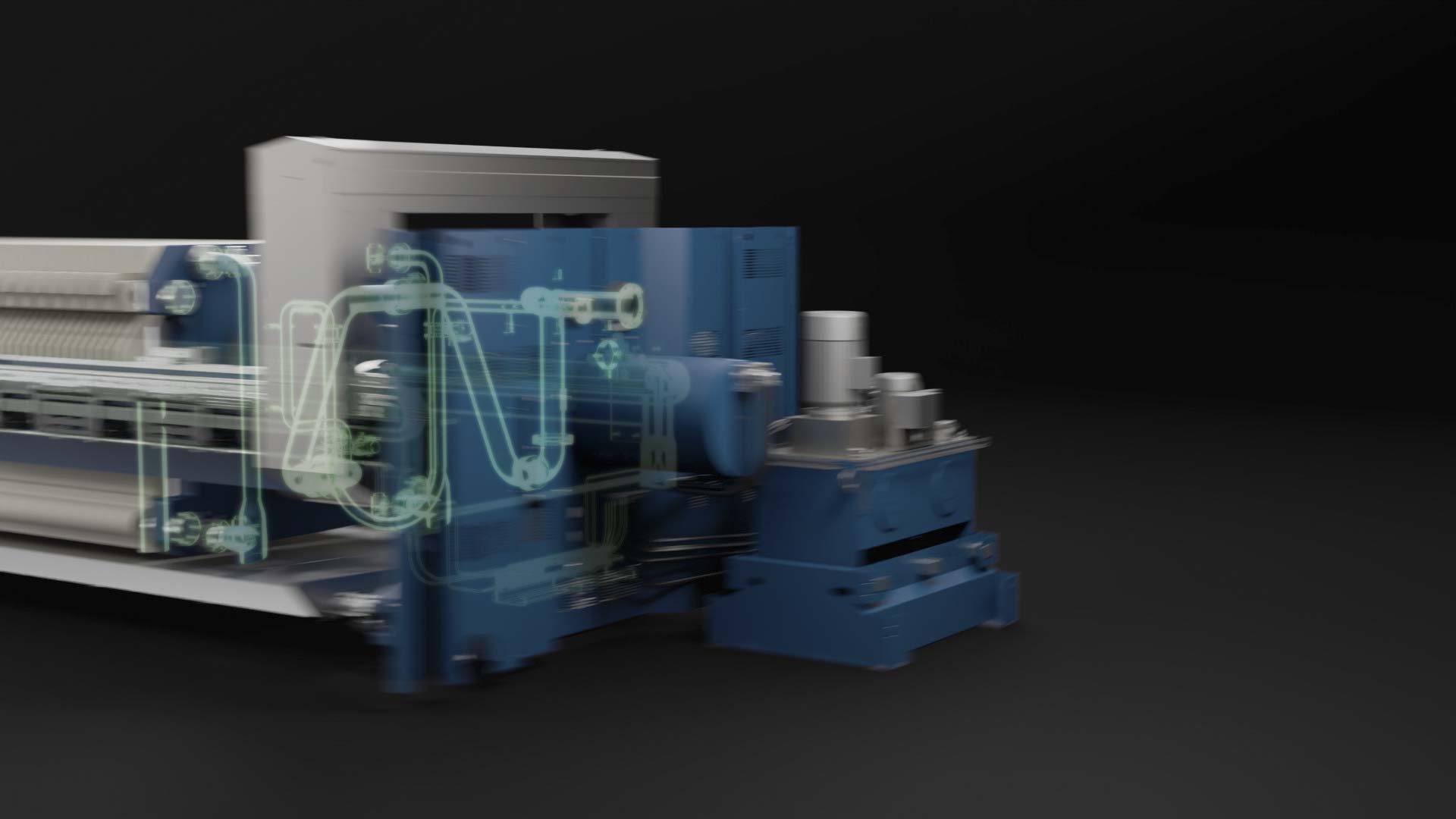

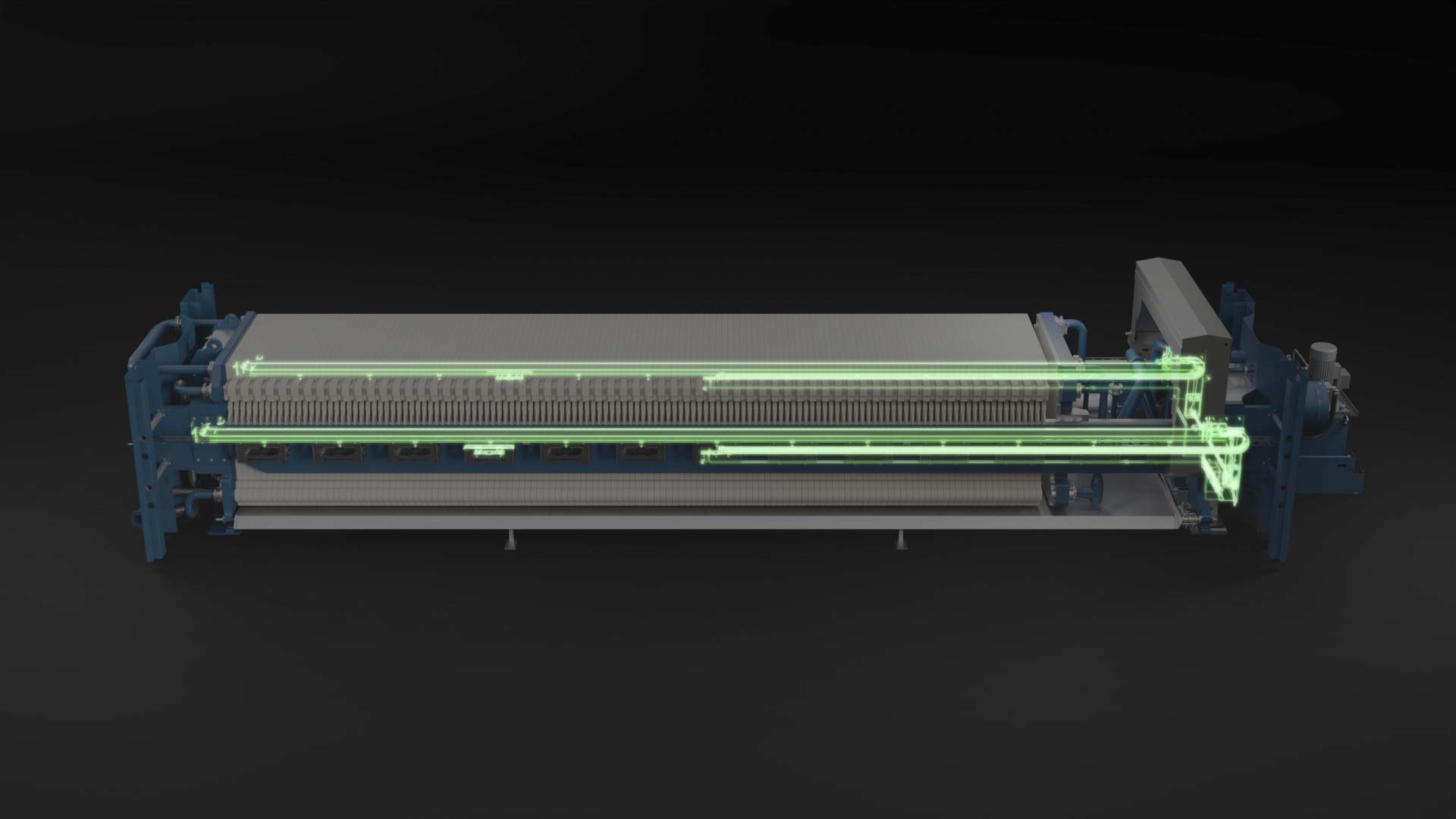

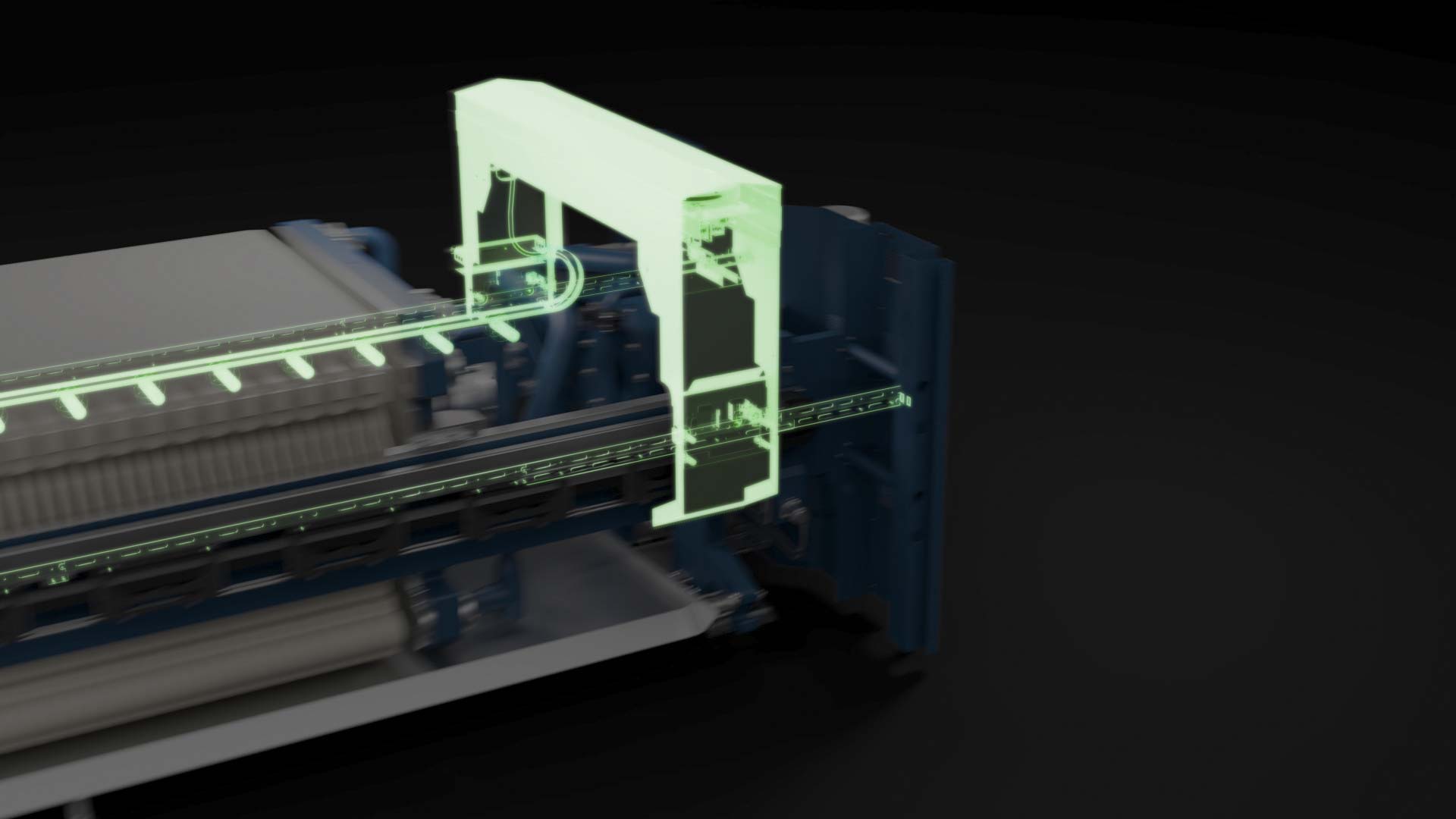

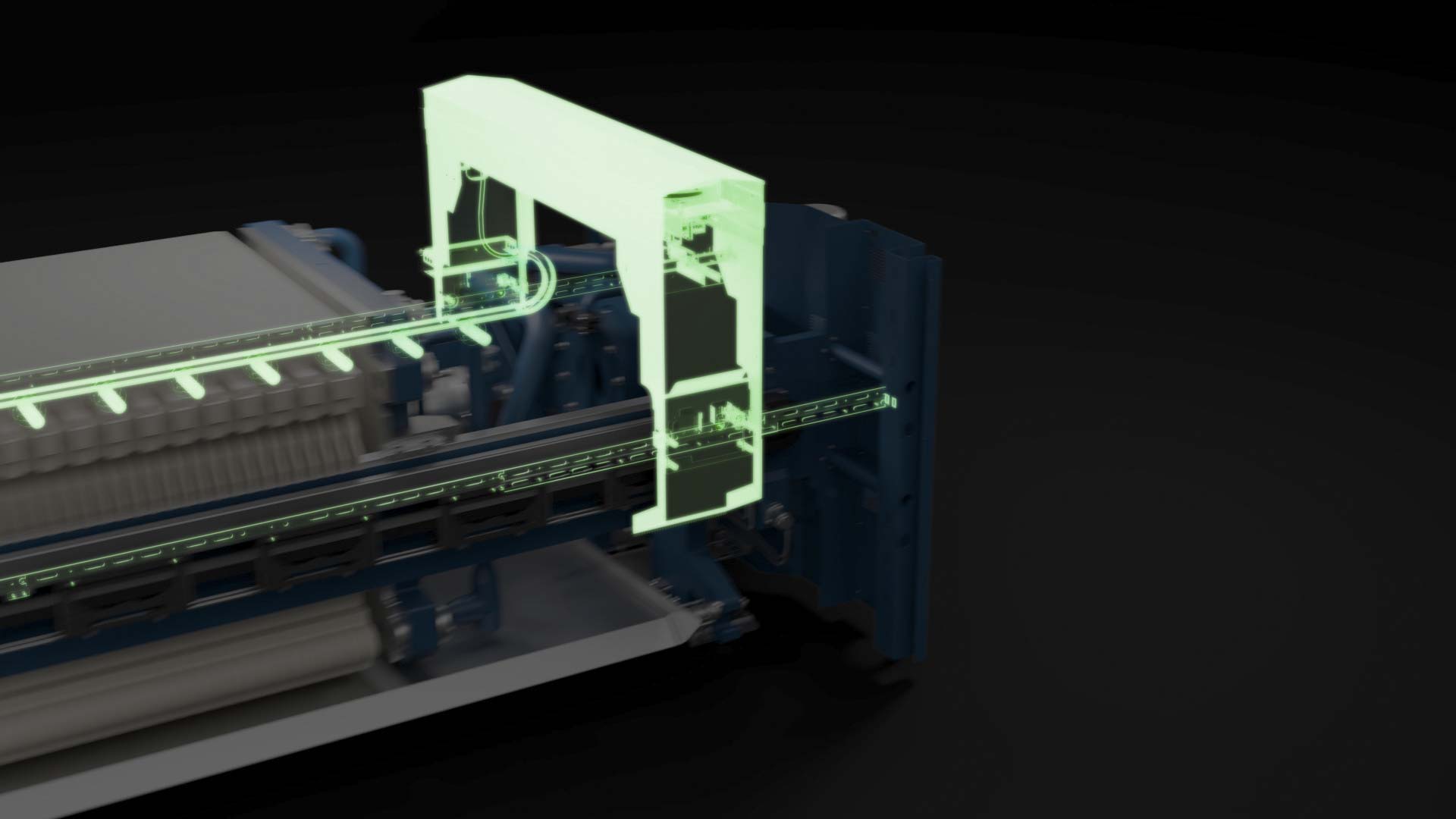

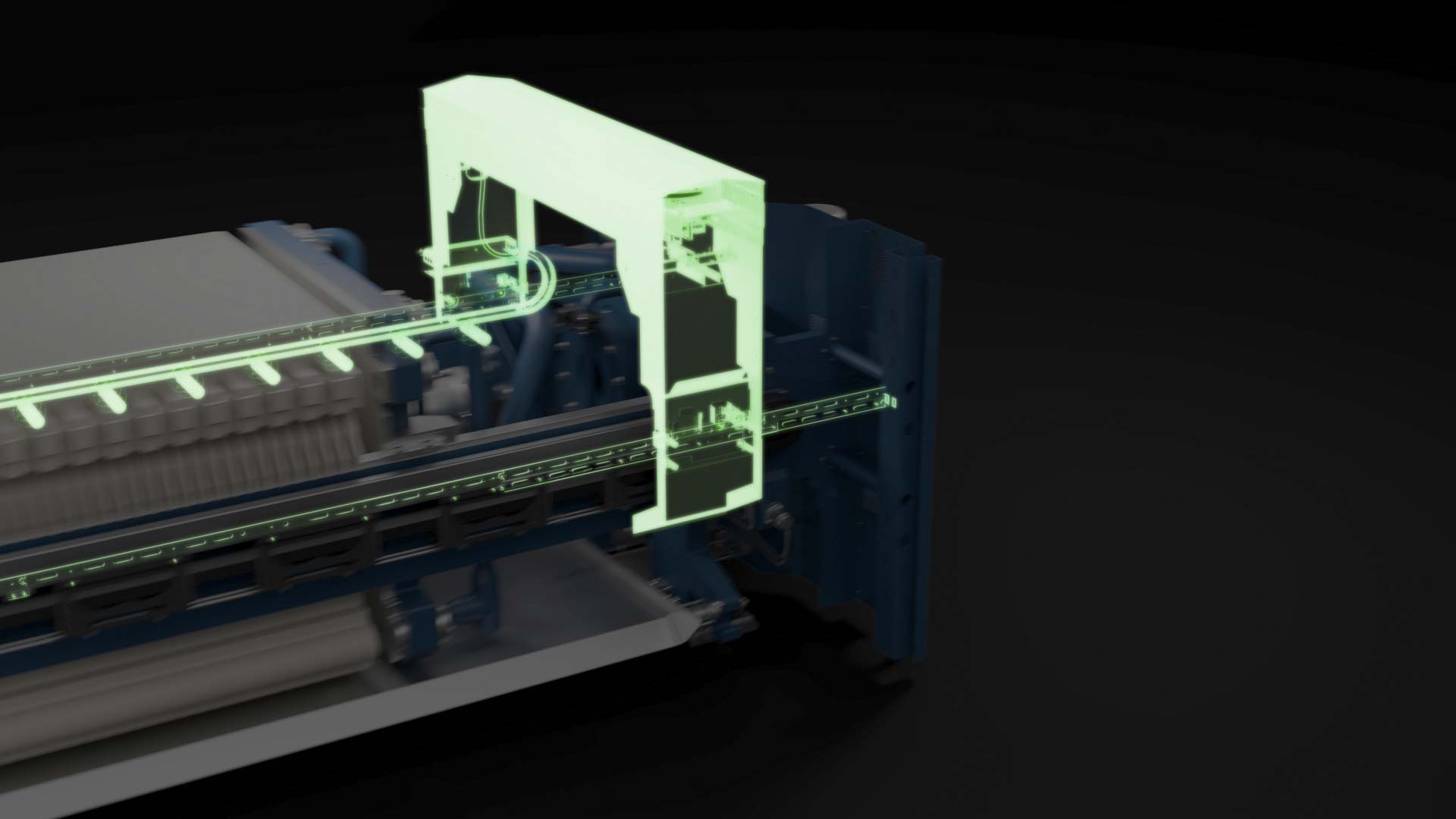

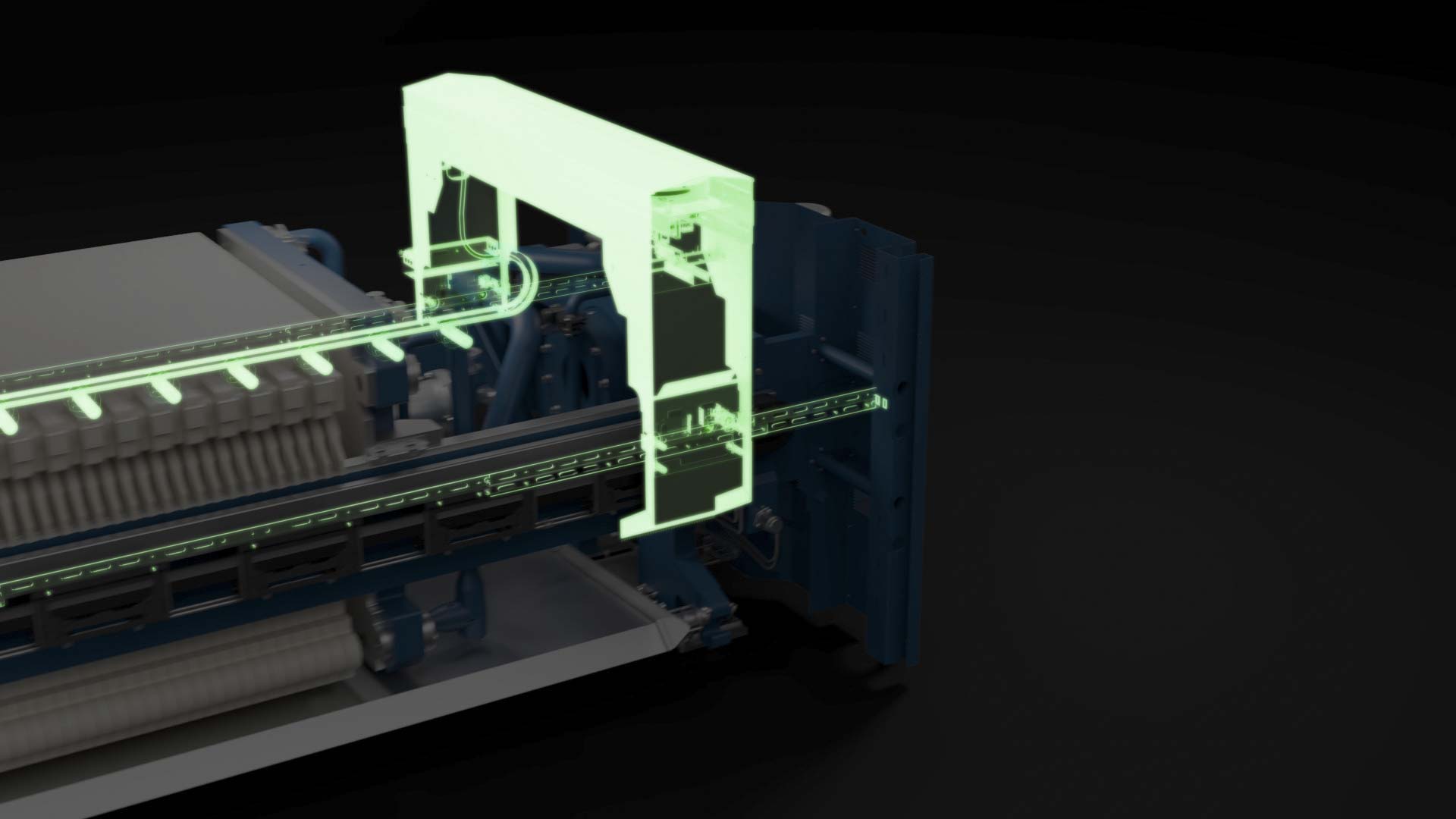

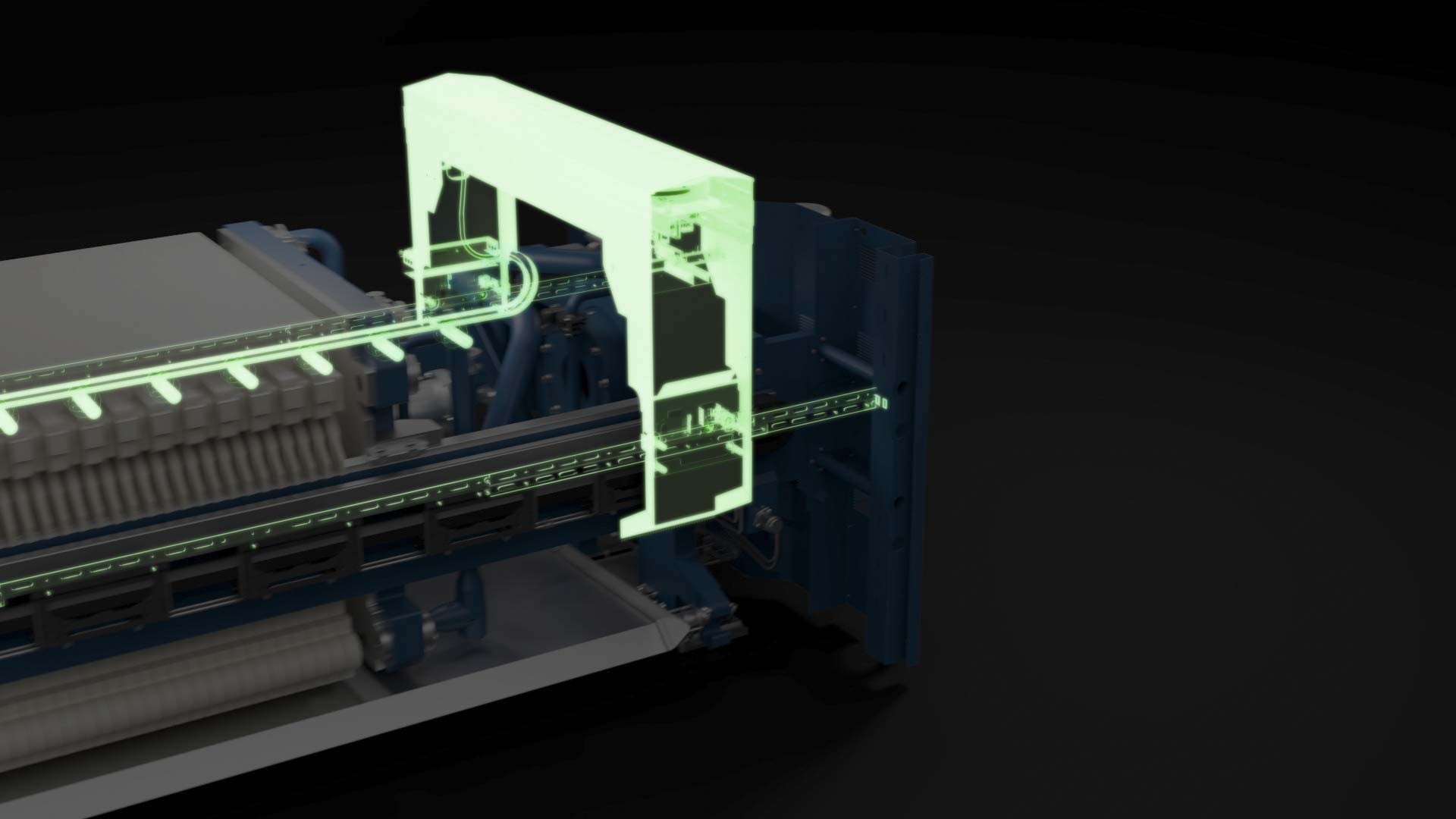

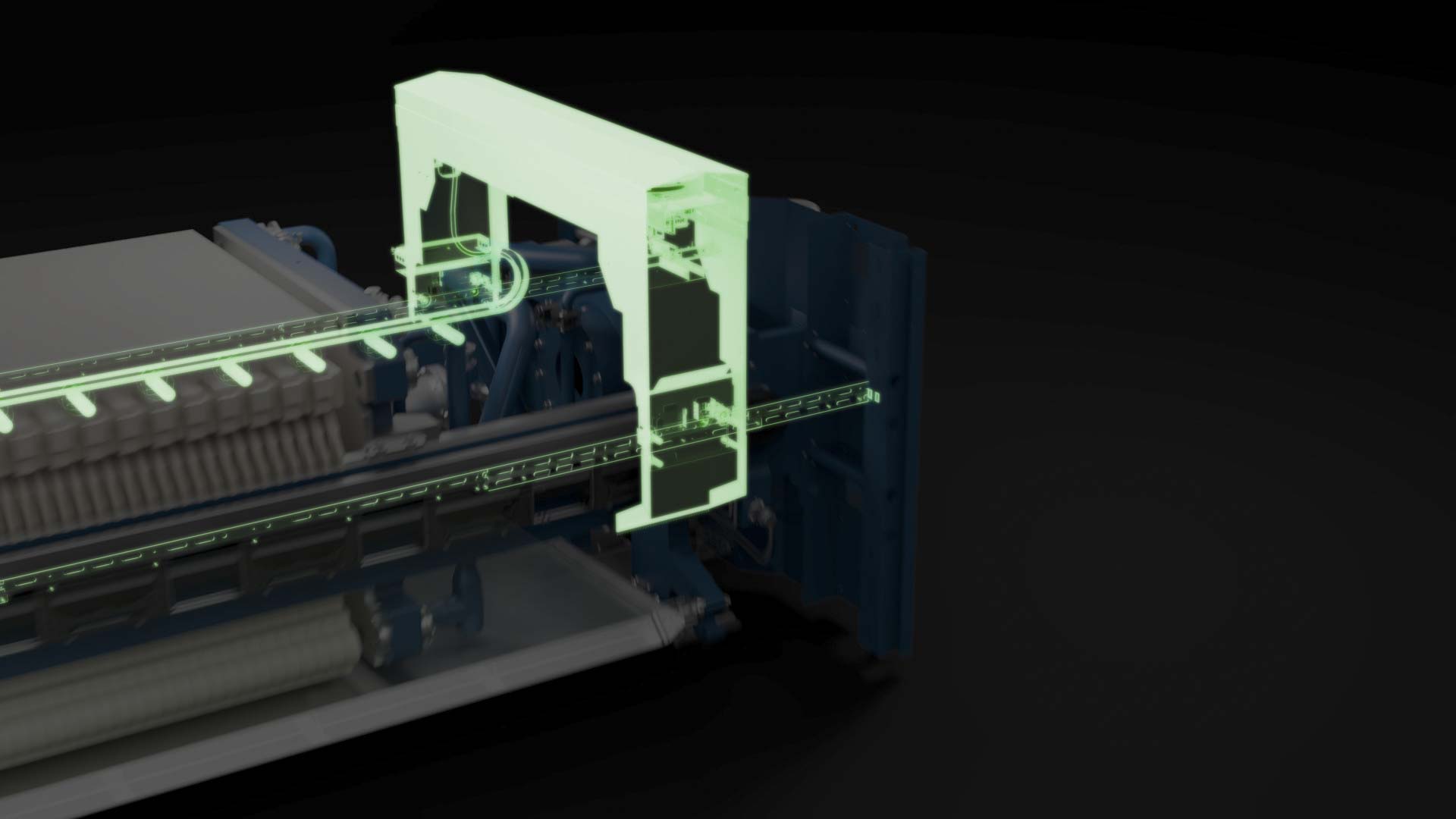

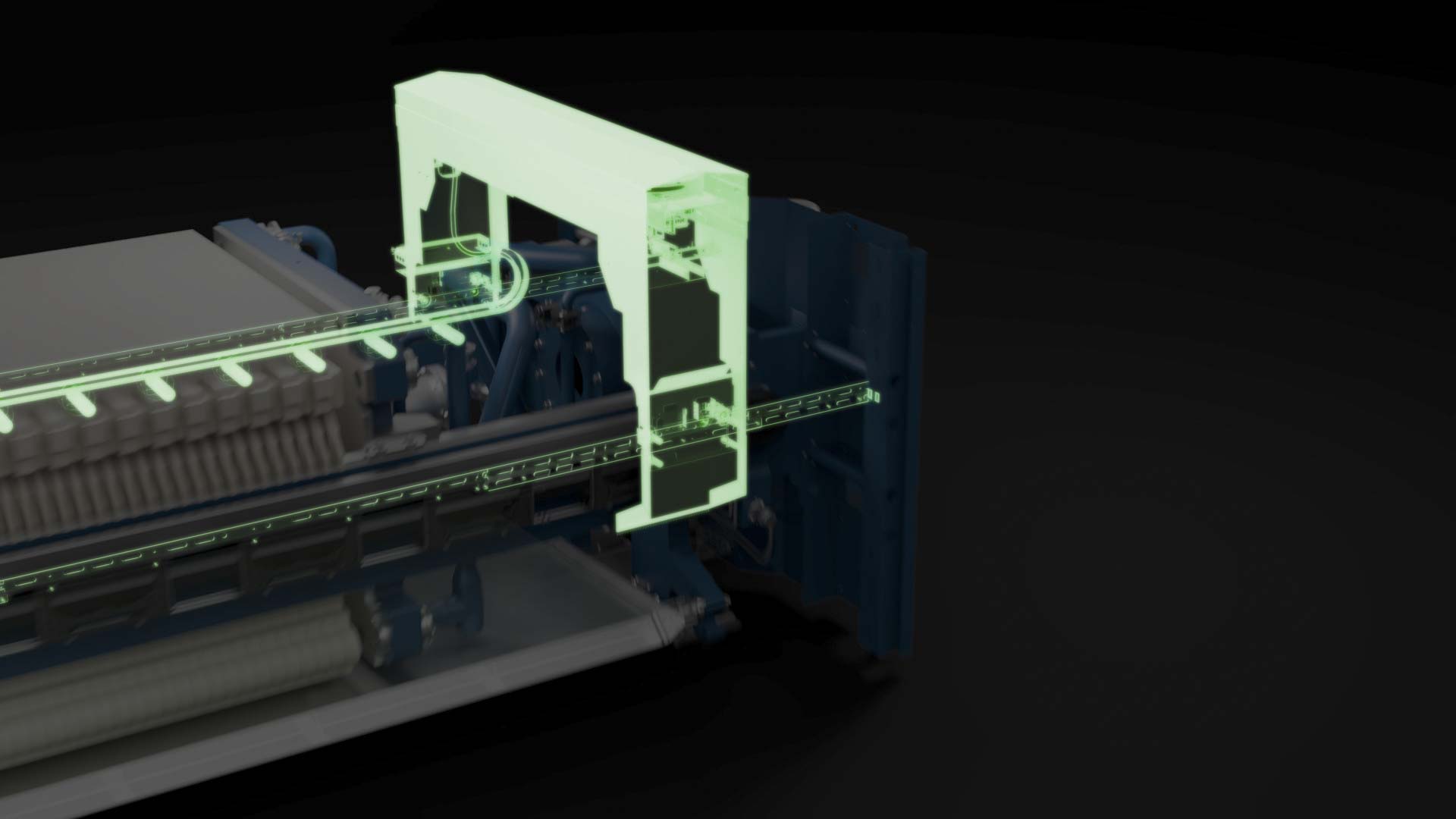

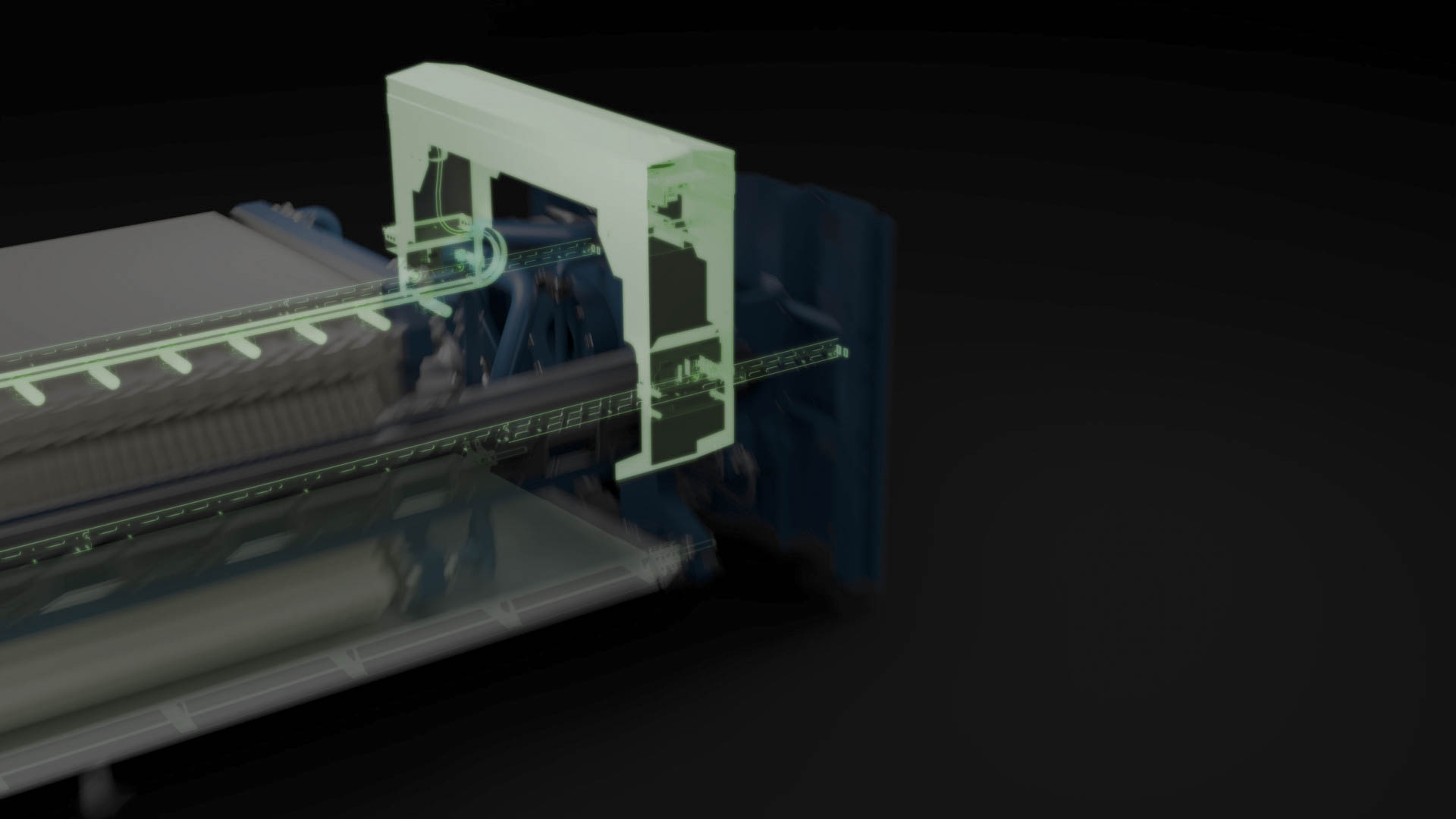

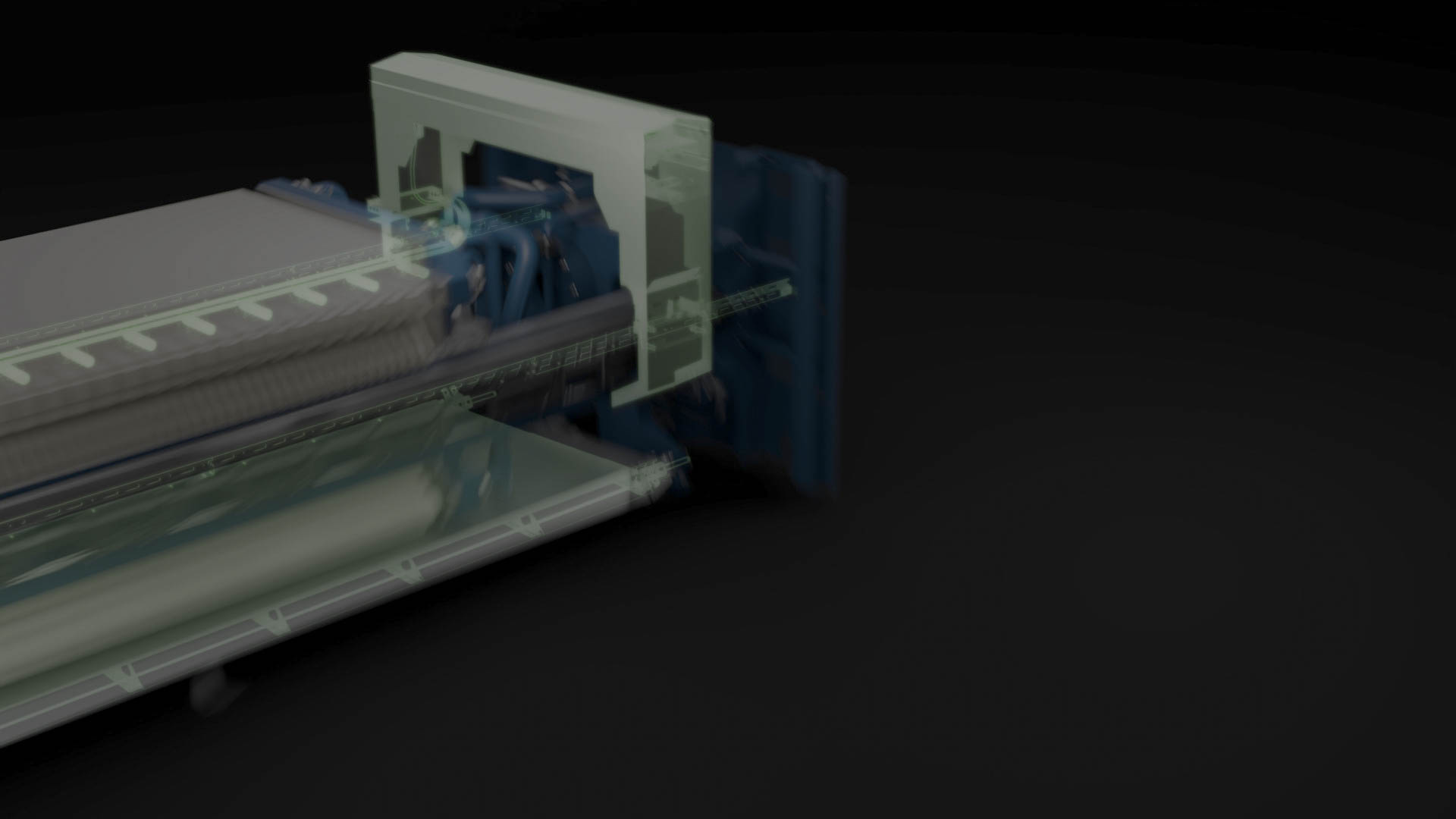

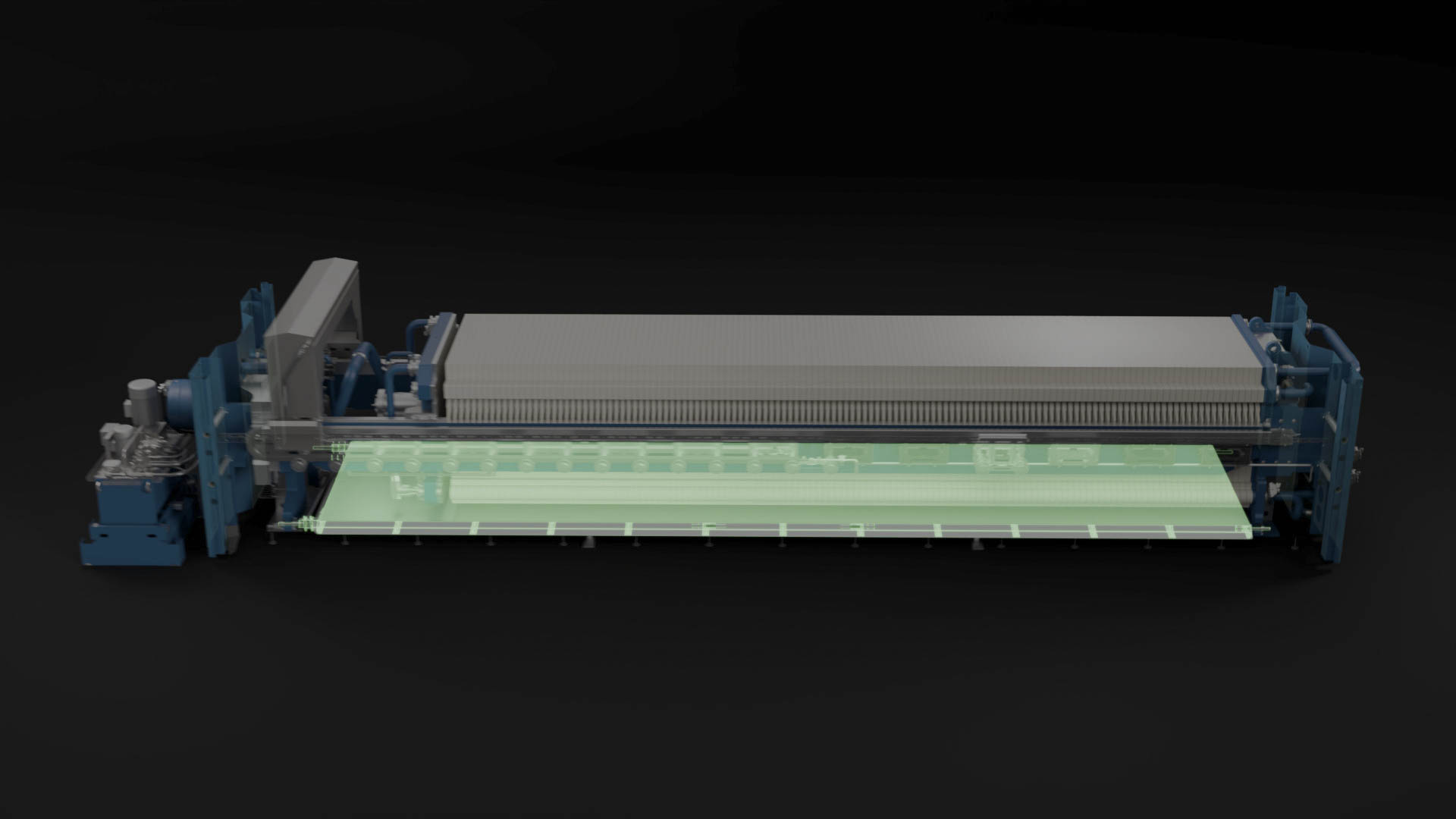

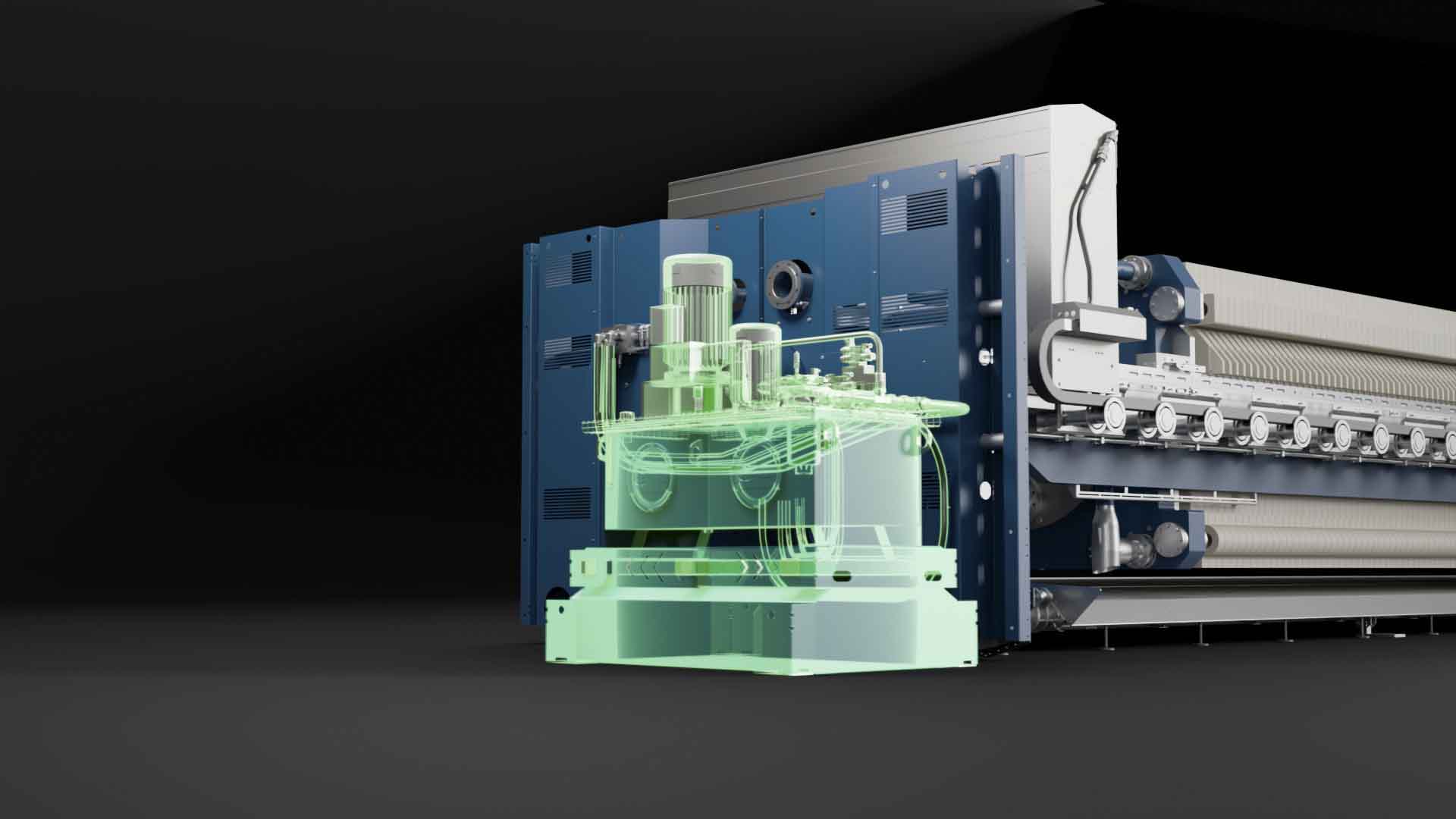

More Than Just Add-Ons: Engineering & Automation Modules

Our automation modules are precision-engineered tools that transform your filter press into a high-performance, safe, and efficient system. Whether it’s automated plate shifting, innovative filter cake discharge systems, or seamlessly integrated real-time monitoring systems and cleaning technologies, each module is designed to enhance operational efficiency and minimize downtime.

With cutting-edge technology and intelligent automation, you can maximize performance without compromising on safety or efficiency.

Additional Modules

Optimized Performance Down to the Last Detail

Advanced Cake Treatment & Filter Cloth Cleaning

Optimized for Maximum Performance & Longevity

Our advanced cleaning and cake treatment systems are more than just maintenance tools—they are essential for ensuring the long-term efficiency and durability of your filter press. By thoroughly cleaning and drying the filter cake, even under demanding conditions, we help maintain consistent high performance.

Filter Cake Washing

Precision Cleaning for Optimized Processes

Our high-efficiency filter cake washing systems ensure complete penetration and removal of residues and unwanted substances.

- Diagonal or Crossflow Washing: Delivers uniform washing across the entire cake structure.

- Gap Washing: Targets stubborn deposits for thorough cleaning.

- Optional Filter Cake Washing Skid: A versatile, fully integrated system customized to your specific process requirements.

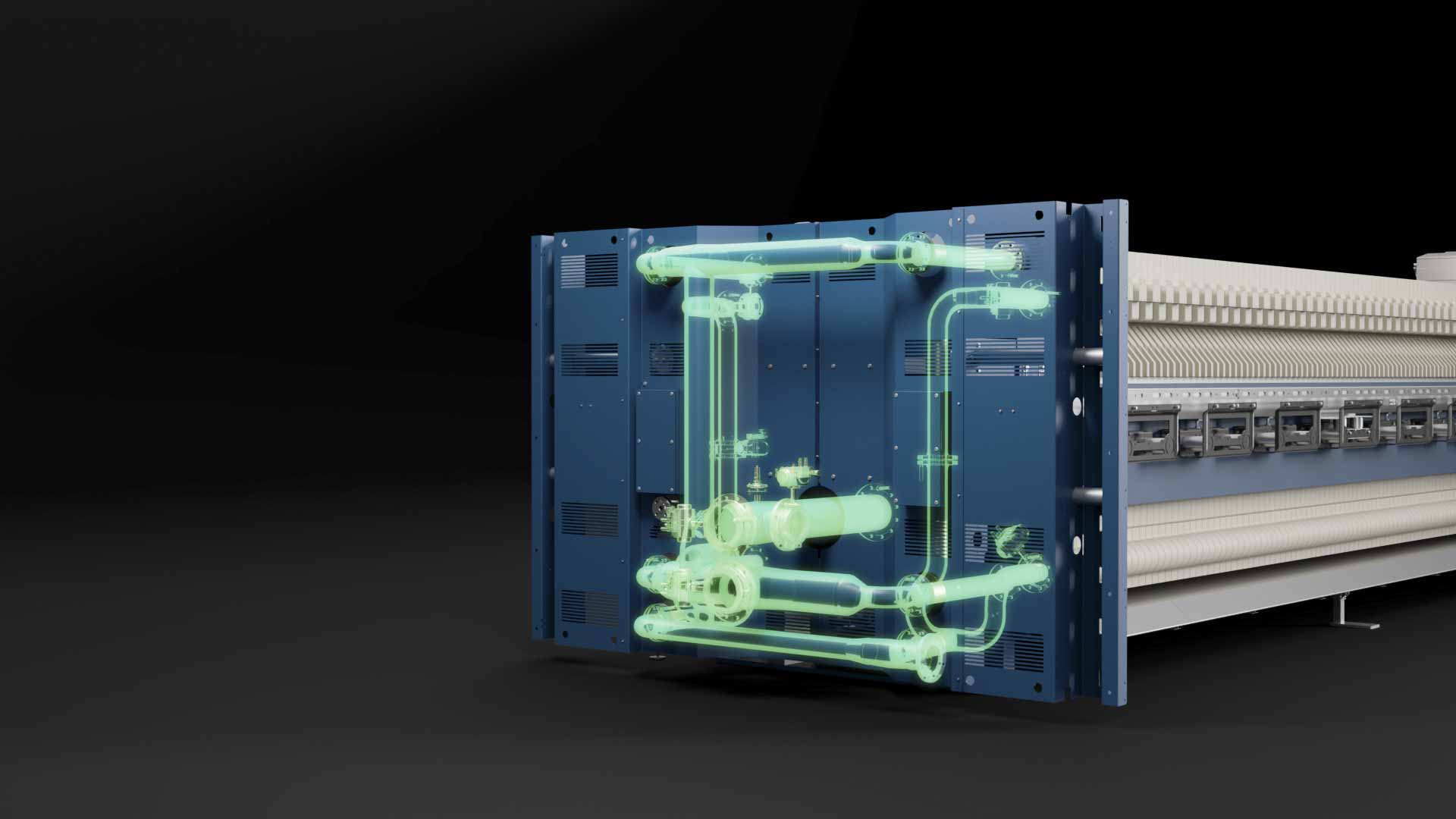

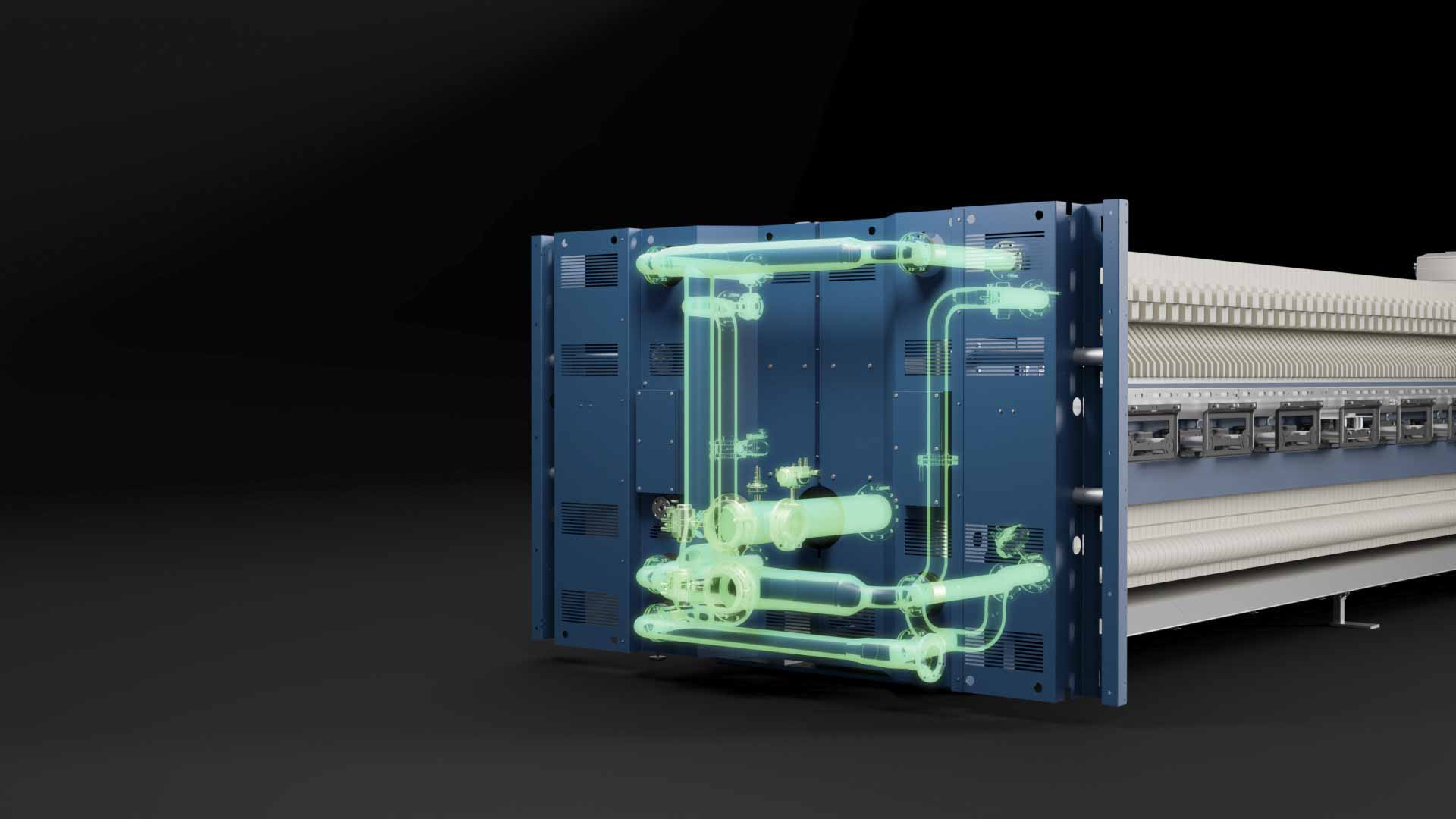

Advanced Cake Treatment

Maximum Drying Efficiency & Purity

Our core rinsing and core blowing systems ensure thorough flushing and removal of residual filtrate from the plate pack, preventing clogging and contamination.

- Core Rinsing – Removes trapped solids and ensures consistent filter performance.

- Core Blowing – Clears residual slurry, improving cake dryness.

- Filter Cake Dry Blowing – Reduces moisture content for enhanced downstream processing.

- Filtrate Blowing – Clears the filtrate channel for optimized drying efficiency.

- Optional Hot Water Cake Drying – Increases solid concentration significantly, preparing the cake for further processing or disposal.

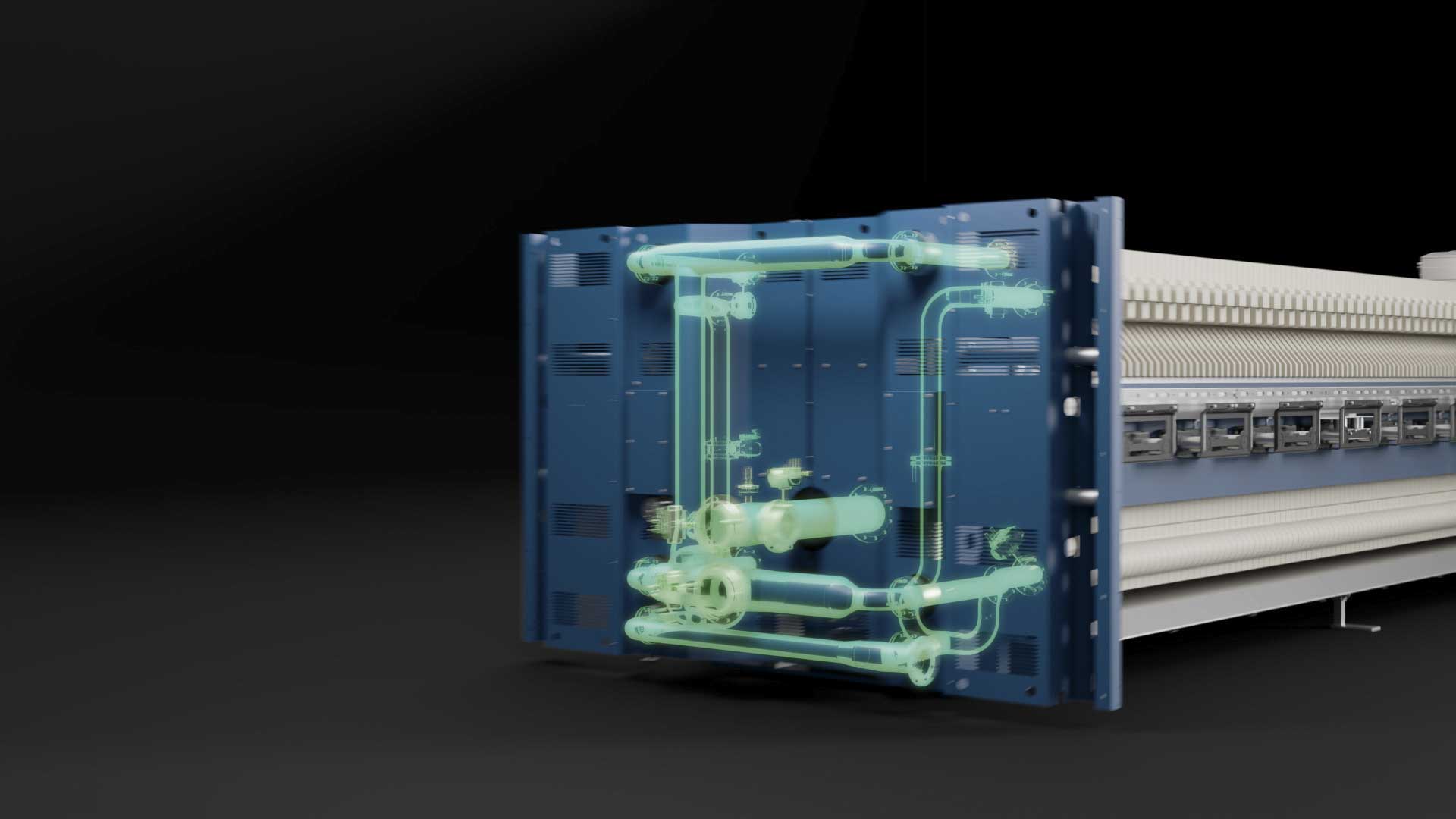

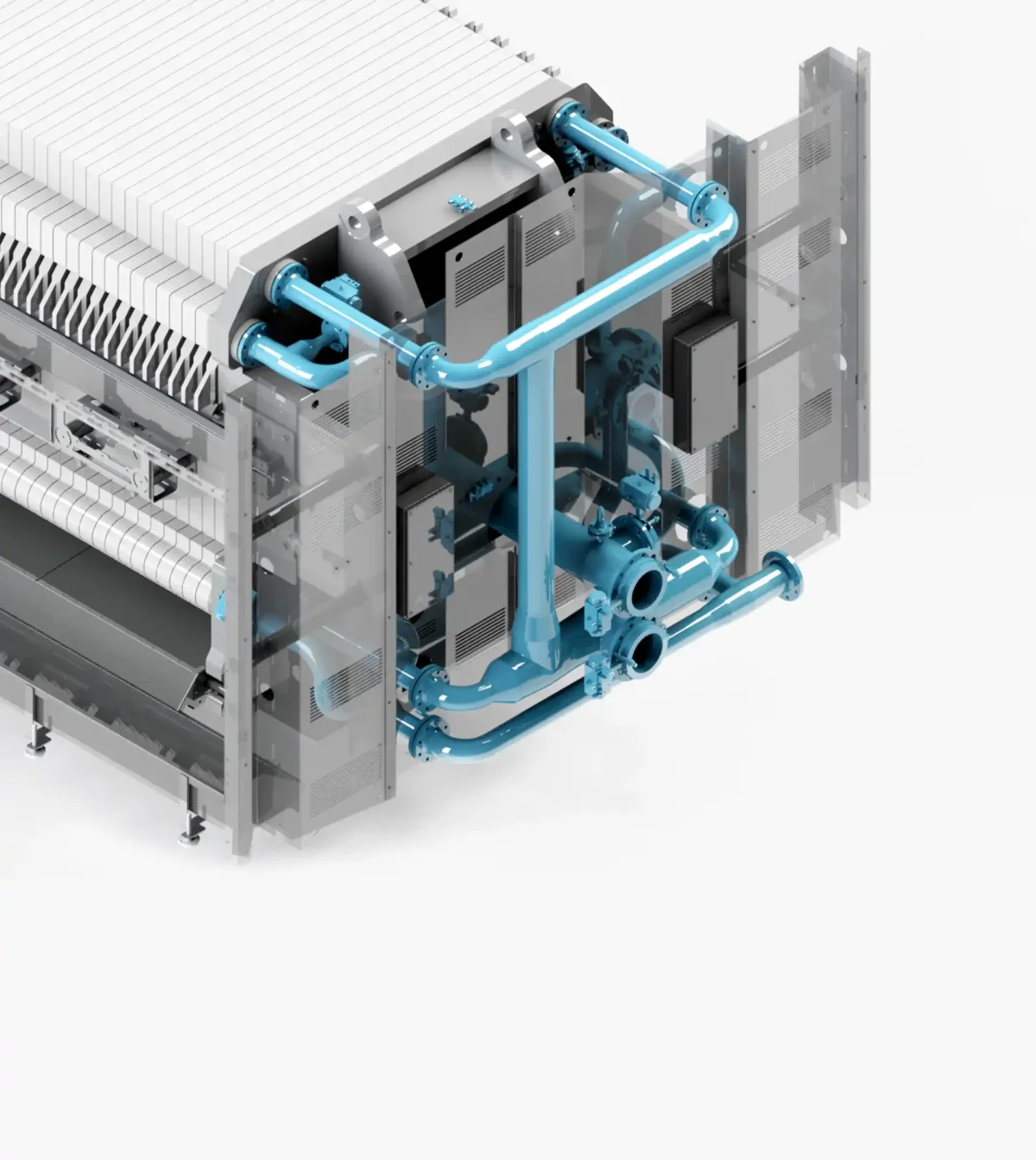

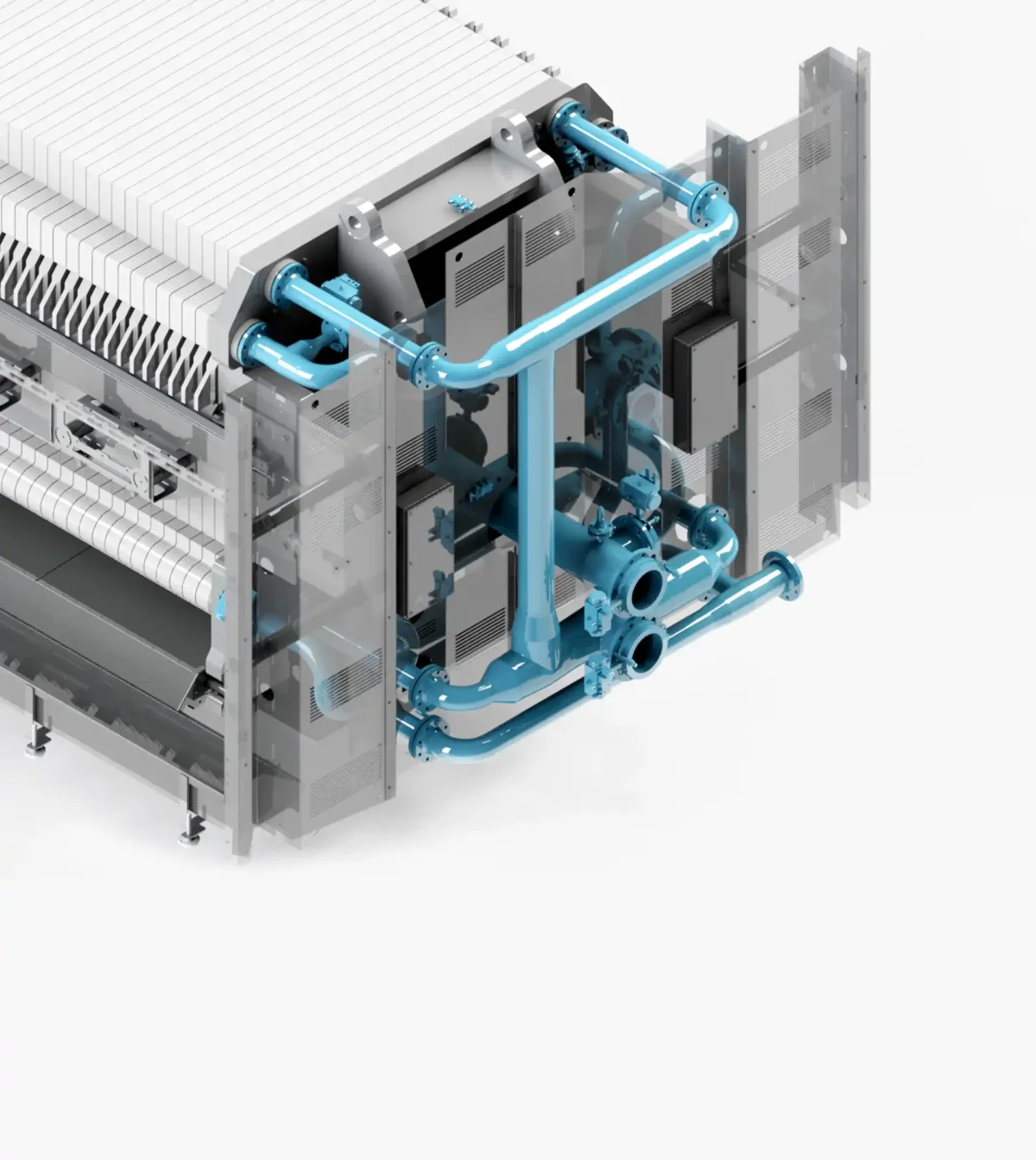

Filter Cloth Acid Washing

Superior Cleaning for Extended Lifespan & Optimal Filtration Performance

Our filter cloth acid washing systems effectively remove lime and metal deposits directly within the filter press. Available in both dynamic and static configurations, they provide maximum flexibility to accommodate various operational needs.

- Dynamic Acid Washing – High-performance cleaning for continuous operation.

- Static Acid Washing – Optimized for batch processing and deep cleaning.

- Acid Washing Skid – Fully integrated system for controlled, efficient cleaning.

- Acid Mixing Station – Ensures precise dosing and safe acid preparation.

Detailed consulting & innovative engineering

We implement your requirements quickly and precisely! With our in-house development and production, we work with you to create tailor-made solutions. We master even complex challenges! See for yourself.

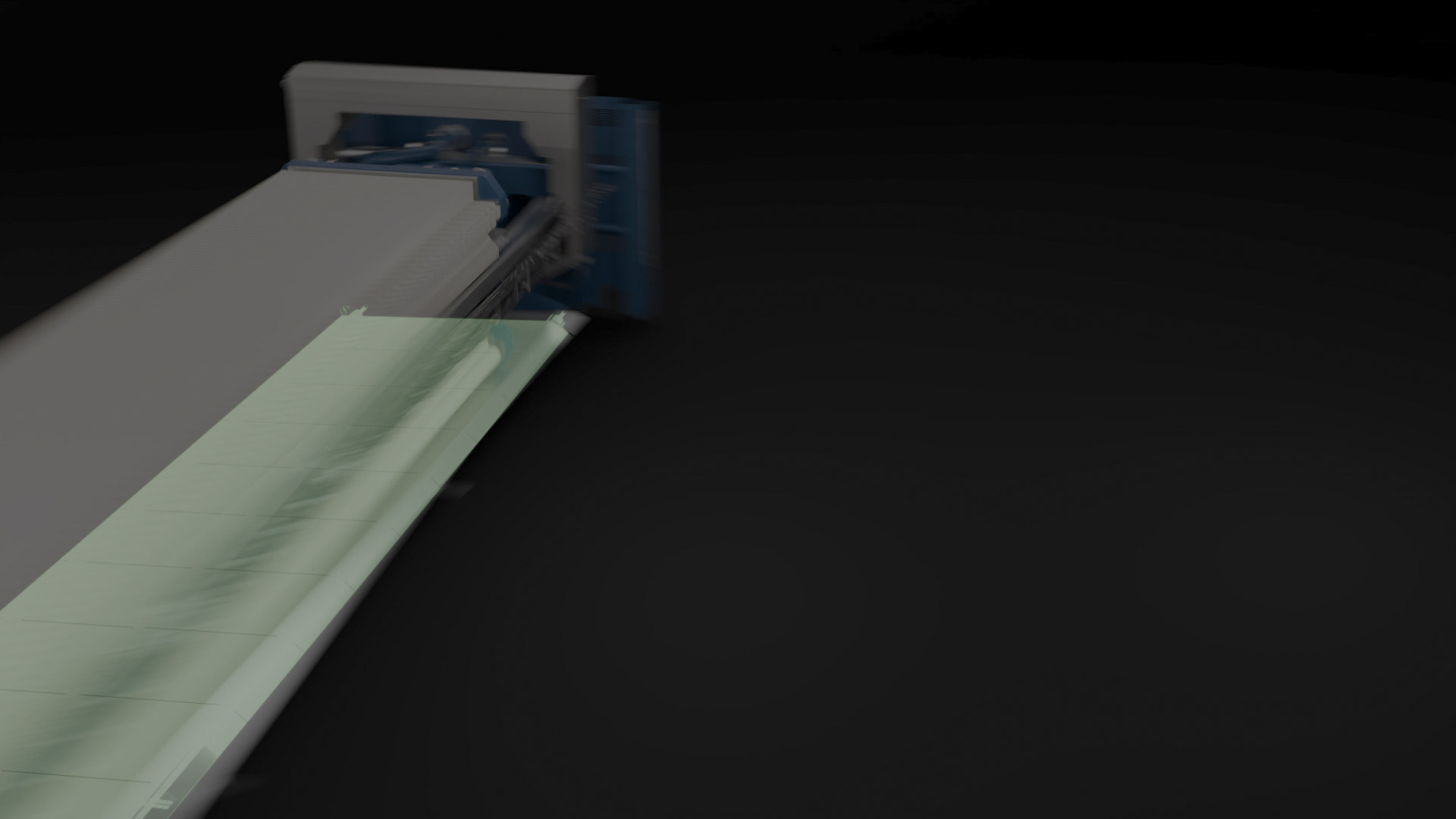

Custom System Peripherals

From robust platforms and intelligent conveyor systems to custom-built containers—MSE provides fully integrated solutions that seamlessly enhance your filter press operations.

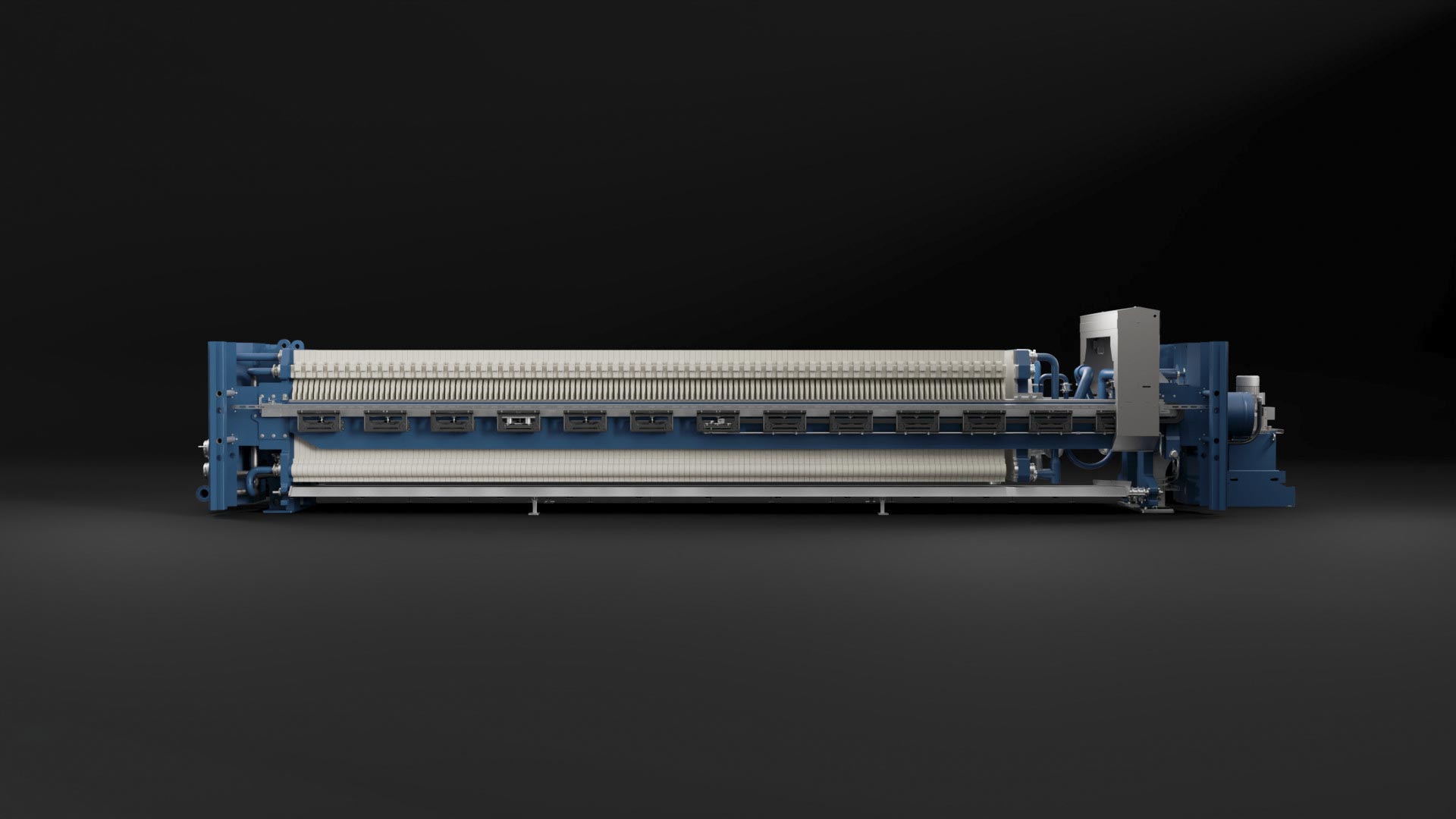

Membrane Filter Presses & Chamber Filter Presses

MSE filter presses deliver top efficiency, durability, and customized technology—designed to meet your industry’s highest standards.

Contact

Get in Touch Speak with Our Experts

How can we support you? We’re here for you throughout the entire

lifecycle of your filter press.